19

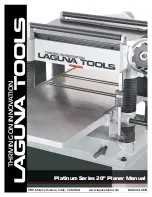

3. Move the gauge block (A) Fig. 52 without the feeler

gauge under one end of the infeed roller (C). The

bottom of the infeed roller (C) should touch the top

of the gauge block (A).

4. To adjust, loosen the nut (D) Fig. 52 and turn the

adjusting screw (E) until that end of the infeed roller

touches the top of the gauge block. Tighten the nut

(D).

5. Repeat this adjustment with the gauge block on the

opposite end of the infeed roller.

1. Make sure the knives are adjusted properly as ex plained under

How To Check, Adjust, And Re place Knives.

2. Place the gauge block (A) Fig. 53 on the table directly underneath the cutterhead. Place a 0.040" (1.01 mm) feeler

gauge (B) on top of the gauge block. Raise or lower the head assembly until one of the knives touches the feeler

gauge. Tighten the head locking knobs.

3. Move the gauge block (A) Fig. 54 without the feeler gauge under the end of the outfeed roller (C). The bottom of the

out-feed roller (C) should touch the top of the gauge block (A).

4. To adjust, loosen the nut (D) Fig. 54 and turn the screw (E) until the outfeed roller is properly adjusted.

5. Repeat this adjustment procedure on the opposite end of the outfeed roller.

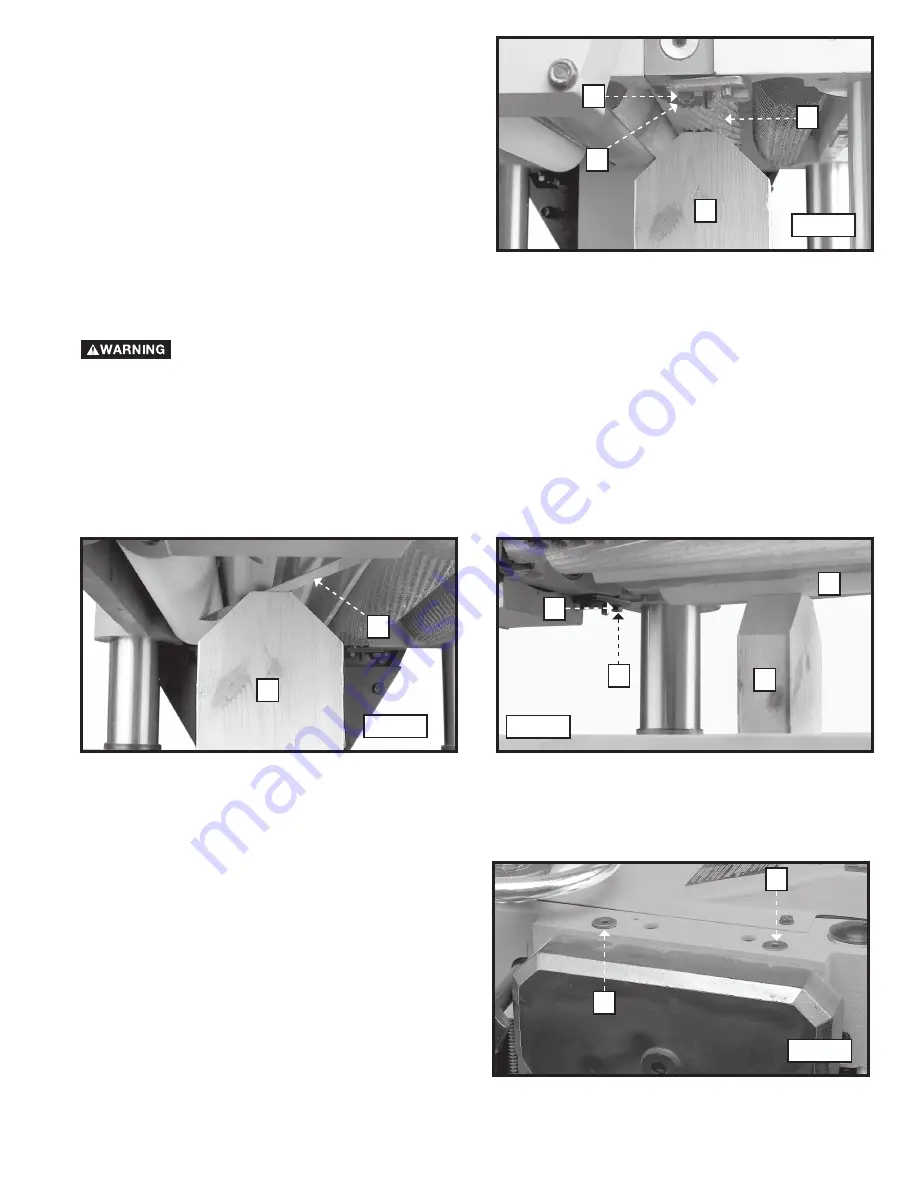

HOW TO ADJUST THE TENSION OF THE INFEED AND OUTFEED ROLLERS

The infeed and outfeed are under spring tension. The

tension should be sufficient to feed the stock uniformly

without slip ping, but should not be so tight that it causes

damage to the board. The tension should be equal at

both ends of each roller.

To adjust the spring tension of the infeed roller, turn two

screws, one of which is shown at (A) Fig. 55. The other

screw is located on the opposite side of the machine.

Adjust the two screws (A) until

FOUR

threads show

above the table casting. Further tension adjustment may

be necessary.

To adjust the spring tension of the outfeed roller, turn two

screws, one of which is shown at (B) Fig. 55. The other

screw is located on the opposite side of the machine.

Adjust the two screws (B) until

ONE

thread shows above

the table casting. Further tension adjustment may be

necessary.

A

E

D

C

HOW TO ADJUST THE HEIGHT OF THE OUTFEED ROLLER

A

B

Fig. 52

Disconnect the machine from the power source.

The outfeed roller was adjusted at the factory to be

0.040" (1.01 mm) below the cutting circle

. To check and adjust

the height of the outfeed roller:

A

C

E

D

Fig. 53

Fig. 54

A

B

Fig. 55