Most paper jams can be avoided by correctly loading paper and specialty media in the printer.

The following hints can help prevent paper jams:

•

Use only the recommended print media.

•

Do not overload the print media sources. Make sure the stack height does not exceed the maximum height

indicated by the stack line on the labels in the sources.

•

Do not load wrinkled, creased, damp, or curled print media.

•

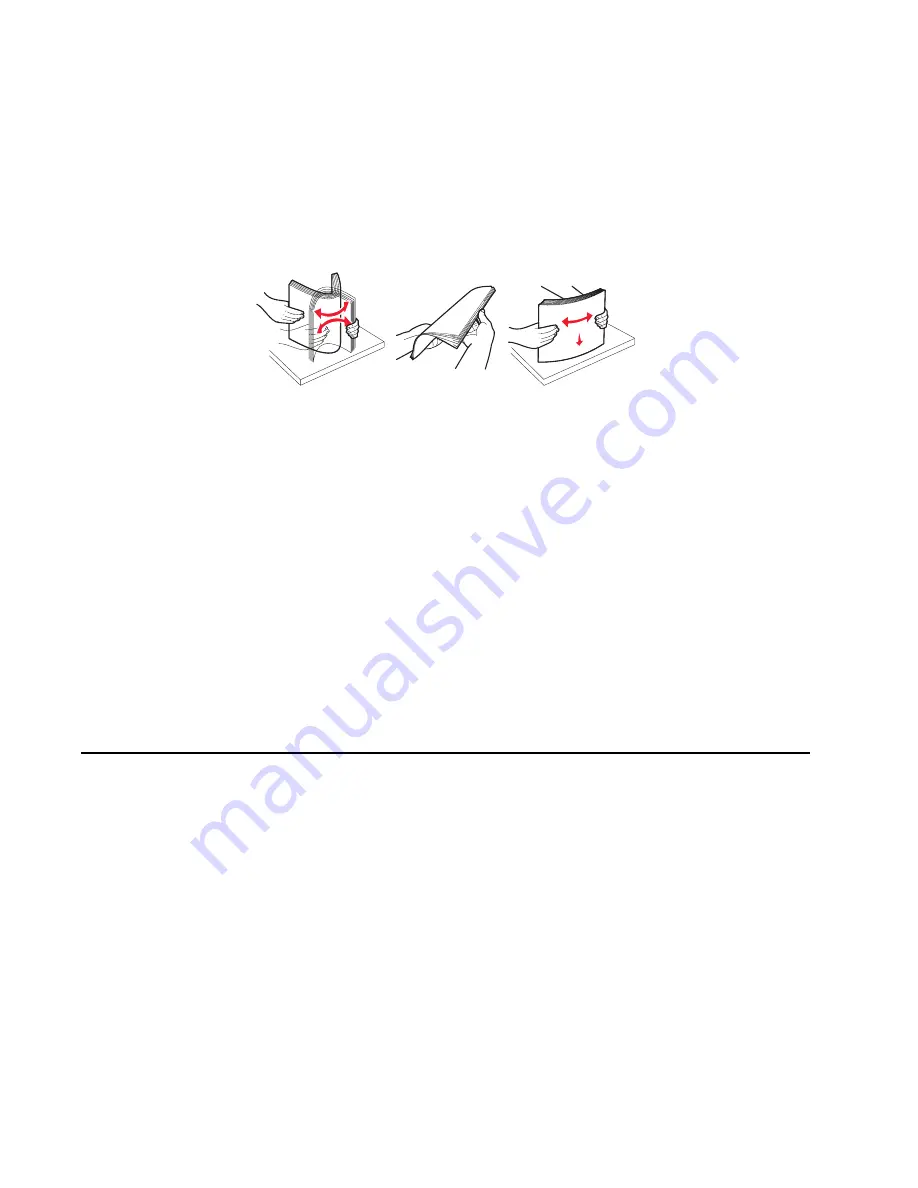

Flex, fan, and straighten print media before loading it. If jams do occur with the print media, then try feeding

one sheet at a time through the manual feeder.

•

Do not mix print media sizes, weights, or types in the same print media source.

•

Push all trays in firmly after loading them.

Note:

Make sure the media stack is below the maximum media fill indicators on the 250-sheet tray before

pushing the tray into the printer.

•

Make sure paper guides are positioned before loading the paper or specialty media.

•

Do not remove trays while a job is printing.

•

Before loading transparencies, fan the stack to prevent sheets from sticking together.

•

Do not use envelopes that:

–

Have excessive curl

–

Are stuck together

–

Are damaged in any way

–

Contain windows, holes, perforations, cutouts, or embossments

–

Have metal clasps, string ties, or metal folding bars

–

Have postage stamps attached

–

Have any exposed adhesive when the flap is in the sealed position

printing environment.

Tools

The removal and adjustment procedures require the following tools and equipment:

•

Spring hook

•

Needle nose pliers

•

Volt-ohmmeter

•

#1 and #2 Phillips screwdriver

•

Slotted screwdriver

1-8

•

Use only recommended media. Refer to the

Card Stock & Label Guide

available on the Dell Web site

at

www.dell.com

for more information about which media provides optimum results for the current

Summary of Contents for Inspiron One 2330

Page 1: ...Dell 2330d dn Service Manual 11 Dec 2008 ...

Page 6: ...vi ...

Page 11: ...Notices and safety information xi ...

Page 12: ...xii ...

Page 26: ...1 10 ...

Page 96: ...6 Remove the screw D from the gear E 7 Remove the plastic bushing F 4 14 ...

Page 103: ...Repair information 4 21 5 Disconnect the AC cable C 6 Disconnect the thermistor cable D C B D ...

Page 117: ...Repair information 4 35 5 Remove the three screws B from the left door mount B ...

Page 120: ...8 Use a screwdriver to pop the inner shaft lock B loose 9 Remove the inner shaft lock C 4 38 ...

Page 123: ...Repair information 4 41 5 Remove the e clip B 6 Remove the media feed clutch with cable C ...

Page 129: ...Repair information 4 47 7 Open the front access door and remove the lower paper guide ...

Page 137: ...Repair information 4 55 4 Tilt the rear cover and remove ...

Page 150: ...Controller board connector pin values 5 2 ...

Page 154: ...6 2 ...

Page 156: ...Assembly 1 Covers 4 3 1 5 2 9 10 6 7 8 11 12 13 7 2 ...

Page 158: ...Assembly 2 Electronics 5 2 6 3 4 10 11 12 7 13 8 9 1 7 4 ...

Page 160: ...Assembly 3 Frame 7 1 2 5 6 7 12 8 See instruction sheet in the FRU 9 10 11 3 4 3 7 6 ...

Page 164: ...7 10 ...