PRO-TC-MAN-17V01 (0802)

Copyright © 2017 Define Instruments

14

F

_ _ _ AVERAGING SAMPLES

scrolls across the display and toggles with the cur-

rent averaging. Using the

and

buttons, alter the number of input samples

that the controller will average, and then press

.

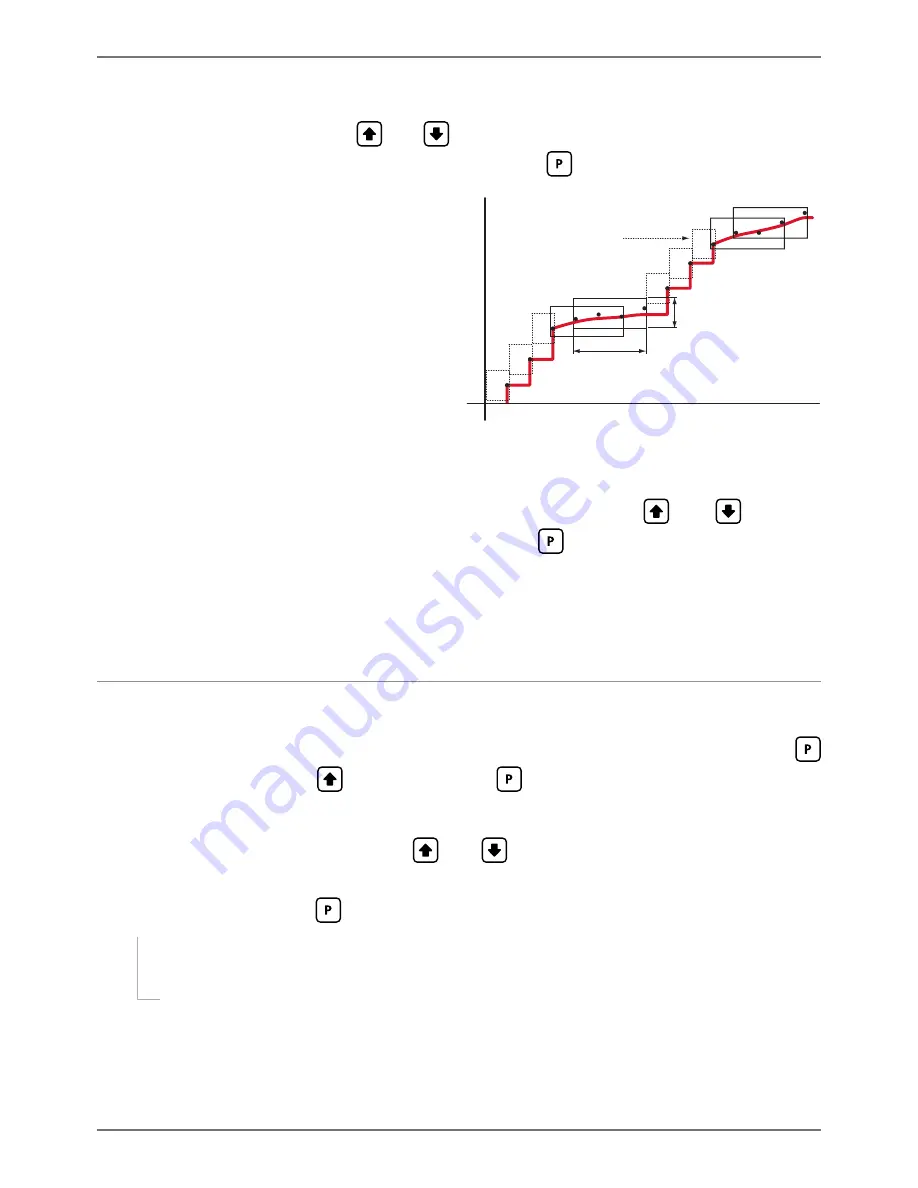

This feature allows signal averaging

of each individual input channel, to

optimise stable measurement. (This is

different from Multi-Channel Averaging,

as explained in 5.4A.)

If the change in input exceeds the averag-

ing window value it will not average, en-

suring fast response when there are large

differences between readings.

Increasing the number of

AVERAGING

SAMPLES

will stabilise measurement, but

it will also slow down response rates.

Inp

ut si

gnal in co

un

ts

Sampling

Averaging window

in displayed counts

Number

of samples

Input exceeds

averaging window

G _ _ _ AVERAGING WINDOW

scrolls across the display and toggles with the cur-

rently selected signal averaging window value. Using the

and

buttons,

alter the signal averaging window. Then press

.

If your input signal contains large noise spikes, you can increase the size of the averaging win-

dow to ensure that these are still averaged. However, increasing the window size too far will re-

duce the ability of the controller to respond quickly to real changes in input signal. Setting

AV-

ERAGING WINDOW

to

0

will give continuous averaging as per the selected averaging samples.

6.3 - Display setup

A _ _ _ DISPLAY SETUP

scrolls across the display and toggles with

SKIP

. Press

to skip to 6.4, or the

button and then

to

ENTER

display setup.

B _ _ _ DISPLAY SOURCE

scrolls across the display and toggles with the currently

selected display source. Use the

and

buttons to choose between:

AUTO

,

TEMP 1

,

TEMP 2

,

TEMP 3

,

TEMP 4

,

AVETMP

,

MAXTMP

, M

INTMP

,

PEAK

, or

VALLEY

. Then press

.

¨

If you selected

AUTO

, continue to 6.3C now.

¨

If you selected something else, skip to 6.3D now.

Note that your options in this step will be limited by the 'Number of Sensors' selected in 6.2D.

For more information about display data sources, see 5.2.

In

Auto

mode, the main display constantly cycles through all available input channels (I.e.

TEMP

1

, followed by the current value for that channel, then

TEMP 2

,

TEMP 3

etc).