13

Step 4

Open the safe guard and clip a 100 gram weight on the inside 12

o’clock position, put down safe guard and press

to start

spin, after spin stop

comes

self-calibration finished

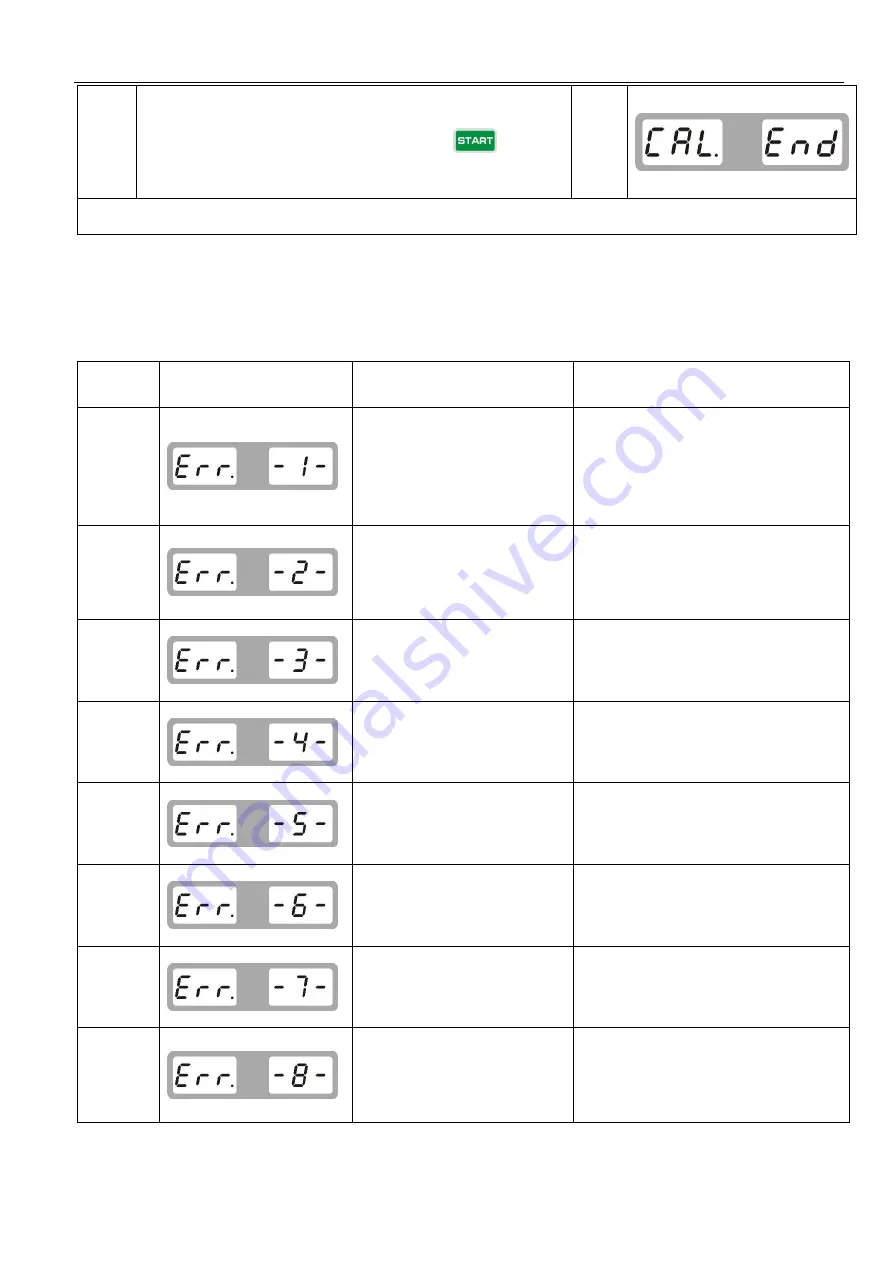

Errors

Various abnormal conditions can arise during machined operation by the microprocessor, if comes the errors, must stop

operation, find the reason and the solution according, if the error persists, consult the supplier.

No.

Errors

Reasons

Solution

1

1

.

No spin

2

.

Shaft spin

1

.

If no spin, check or change power

board

2

.

If spin, check or change position pick

up board and computer board

3. Adjust position pick up board support

2

1

.

No wheel or wheel not locked

tightly

2.Position pick up board

problem

1

.

Lock tightly

2. check or change position pick up board

3

1

.

No enough pressure in wheel

2

.

Wheel distortion

1

.

Add proper pressure in wheel

2

.

Check wheel

4

1.Position pick up board

problem

2. Computer board problem

1.Check or change position pick up board

2.Check or change computer board

5

1. Micro switch problem

2. Computer board problem

1.Check or change Micro switch

2.Check or change computer board

6

1. Power board problem

2. Computer board problem

1.Check or change power board

2.Check or change computer board

7

1.

Program lost

2.

Computer board problem

1.Self calibration

2. Check or change computer board

8

1. No add 100g weight during

self calibration

2

.

Computer board problem

3

.

Power board problem

1. Add 100g weight

2.Check or change computer board

3.Check or change power board