4.5 CleanConnect

®

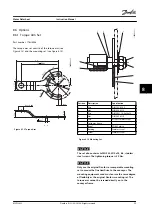

Connection Diagram

shows the connection power plug for OneGearDrive Hygienic DA09LA10 in Y-connection with thermistors.

130BB868.12

V1

W1

U1

U

V

W

2

3

D

C

A

B

1

4

T1

T2

Figure 4.4 CleanConnect

®

OneGearDrive Connection

Description

Inverter output

Pin

Typical cross-section

Maximum cross-section

Motor winding

U

1

1.5 mm

2

/AWG 16

2.5 mm

2

/AWG 14

V

3

W

4

Protective ground

PE

2

1.5 mm

2

/AWG 16

2.5 mm

2

/AWG 14

Temperature protection

1)

KTY 84-130

T1

A

0.75 mm

2

/AWG 20

1.5 mm

2

/AWG 16

T2

B

Table 4.3 CleanConnect

®

OneGearDrive Connection

1) When connected to VLT

®

AutomationDrive FC 302 and VLT

®

Decentral Drive FCD 302, use analog input terminal 54, KTY sensor 1. For

information about parameter setting and programming, refer to the corresponding instruction manual.

T1

KTY 84-130

VLT

®

AutomationDrive FC 302

1)

VLT

®

Decentral Drive FCD 302

1)

T2

KTY sensor 1

Analog input 54

Table 4.4 Connections T1 and T2

1) Only if connected

4.6 Overload Protection

Take note of the relevant circuit diagram for motors with thermally activated winding protection (see

Avoid automatic resetting after the winding has cooled.

The output of the motors is normally adequately rated. The rated current does not represent a measure of gear unit

utilization in these cases and cannot be used as overload protection for the gear unit. In some cases, the way in which the

machine being driven is loaded can exclude any overloading as a matter of course. In other cases, it is necessary to protect

the gear unit by mechanical means (e.g., slip clutch, sliding hub, etc.). This depends on the maximum permissible limit

torque M

LT

in continuous running duty specified on the nameplate.

Electrical Installation

Instruction Manual

16

Danfoss A/S © 08/2014 All rights reserved.

MG75C422

4

4