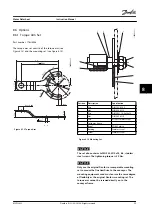

4.4 Cage Clamp Connection Diagram

shows the OneGearDrive DA09LA10 with terminal box in Y-connection and the connection to the thermal

protection.

130BD422.10

V1

W1

U1

U

V

W

PE

U

V

W

T1

T2

Figure 4.3 Cage Clamp Connection Diagram

Description

Inverter output

Color

Typical cross-section

Maximum cross-section

Motor winding

U

Black

1.5 mm

2

/AWG 16

2.5 mm

2

/AWG 14

V

Blue

W

Brown

Protective ground

PE

Yellow/green

1.5 mm

2

/AWG 16

2.5 mm

2

/AWG 14

Temperature protection

1)

KTY 84-130

T1

White

0.75 mm

2

/AWG 20

1.5 mm

2

/AWG 16

T2

Brown

Table 4.1 Cage Clamp Connections

1) When connected to VLT

®

AutomationDrive FC 302 and VLT

®

Decentral Drive FCD 302, use analog input terminal 54, KTY sensor 1. For

information about parameter setting and programming, refer to the corresponding instruction manual.

T1

KTY 84-130

VLT

®

AutomationDrive FC 302

1)

VLT

®

Decentral Drive FCD 302

1)

T2

KTY sensor 1

Analog input 54

Table 4.2 Connections T1 and T2

1) Only if connected

NOTICE!

After connection, tighten all four screws on the terminal box cover. The tightening torque is 3 Nm.

Electrical Installation

Instruction Manual

MG75C422

Danfoss A/S © 08/2014 All rights reserved.

15

4

4