•

•

•

•

•

•

•

•

•

•

-

Use 1 instance of function block

MC_Power_DDS

for every axis to control its power stage. Call up this function block in every PLC

cycle.

Use 1 instance of function block

DD_Power_PSM

for every PSM 510 to control the DC-link voltage on the output lines. Call up

this function block in every PLC cycle.

Use 1 instance of function block

DD_Power_DAM

for every DAM 510 to control the DC-link voltage on the output lines. Call up

this function block in every PLC cycle.

Use 1 instance of function block

DD_Power_ACM

for every ACM 510 to control the DC-link voltage on the output lines. Call up

this function block in every PLC cycle

Call up function blocks that execute (motion) commands at the end of the program.

Do not use any UDTs, POUs, enumerations, or constants starting with the prefix

iDD_

.

Do not change the reference to the axis on a function block while it is busy.

6.17 VLT® Servo Toolbox Software

6.17.1 Overview

The VLT

®

Servo Toolbox is a standalone PC software designed by Danfoss. It is used for parameterization and diagnostics of the

system modules. It is also possible to operate the devices in a non-productive environment.

N O T I C E

The VLT® Servo Toolbox software must be allowed for every firewall profile (private/public/domain).

The VLT

®

Servo Toolbox contains several subtools that provide various functionalities.

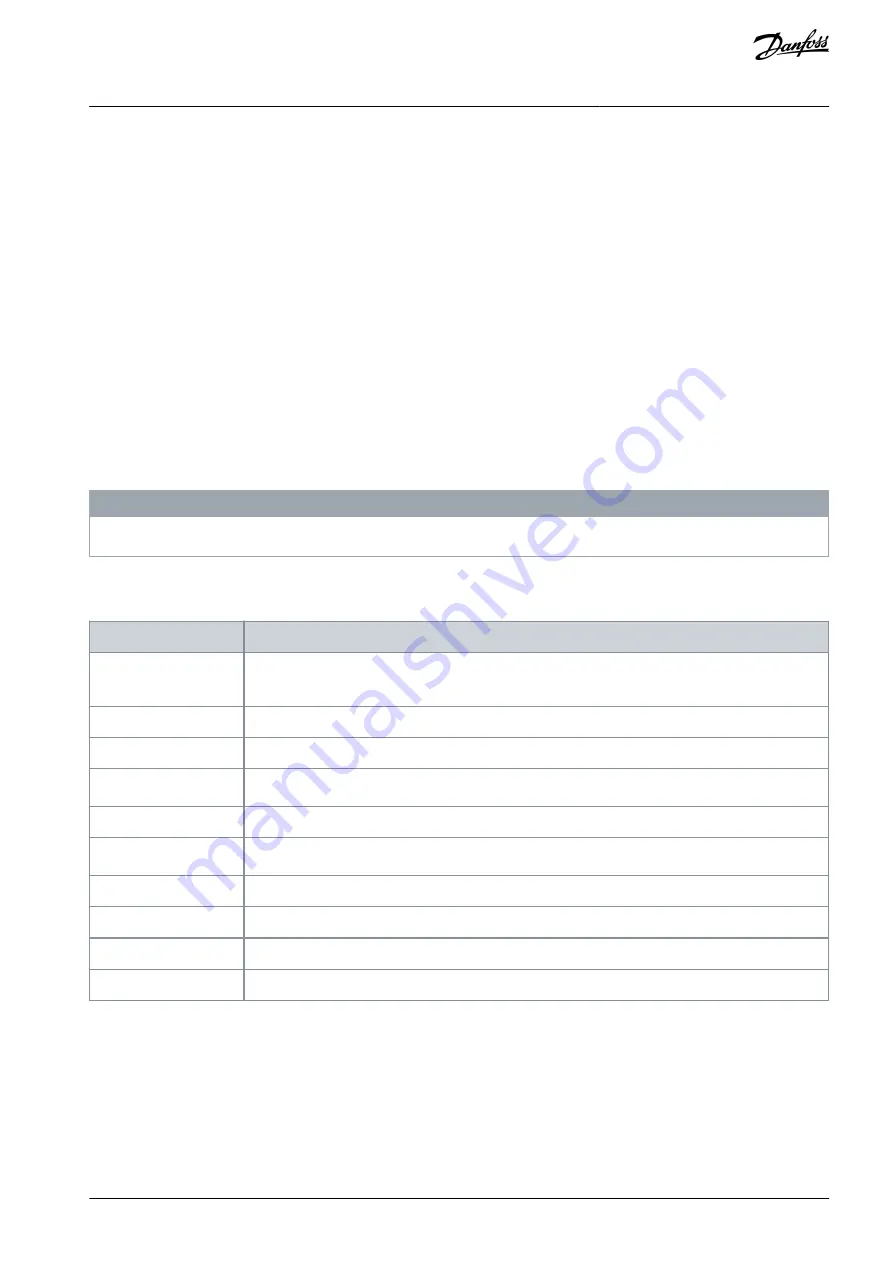

Table 28: Important Subtools

Subtool

Description

Scope

For visualization of the tracing functionality of the servo drives, the Power Supply Module (PSM 510),

the Decentral Access Module (DAM 510), and the Auxiliary Capacitors Module (ACM 510).

Parameter list

For reading/writing parameters.

Firmware update

For updating the firmware on the devices.

Drive control

For operating the servo drives for testing purposes.

PSM control

For operating the Power Supply Module (PSM 510) for testing purposes.

DAM control

For operating the Decentral Access Module (DAM 510) for testing purposes.

ACM control

For operating the Auxiliary Capacitors Module (ACM 510) for testing purposes.

CAM editor

For designing CAM profiles for the servo drives.

Configuration parameter For setting up the motor and feedback parameters, and PID settings.

Drive commissioning

For motor feedback adjustment and inertia measurement.

The detailed description of the VLT

®

Servo Toolbox functionality and the full parameter lists can be found in the

VLT® Servo Drive

System ISD 510, DSD 510, MSD 510 (VLT® Flexmotion

™

) Programming Guide

.

6.17.2 System Requirements

To install the VLT

®

Servo Toolbox software, the PC must meet the following requirements:

Supported hardware platforms: 32.bit, 64-bit.

Supported operating systems: Windows 7, Windows 8.1, Windows 10.

.NET framework version: 4.7.

AQ262449648484en-000101 / 175R1135 | 131

Danfoss A/S © 2020.08

Commissioning

VLT® Servo Drive System ISD 510/DSD 510

Operating Guide