Manual

15

BC251686497767en-US0801

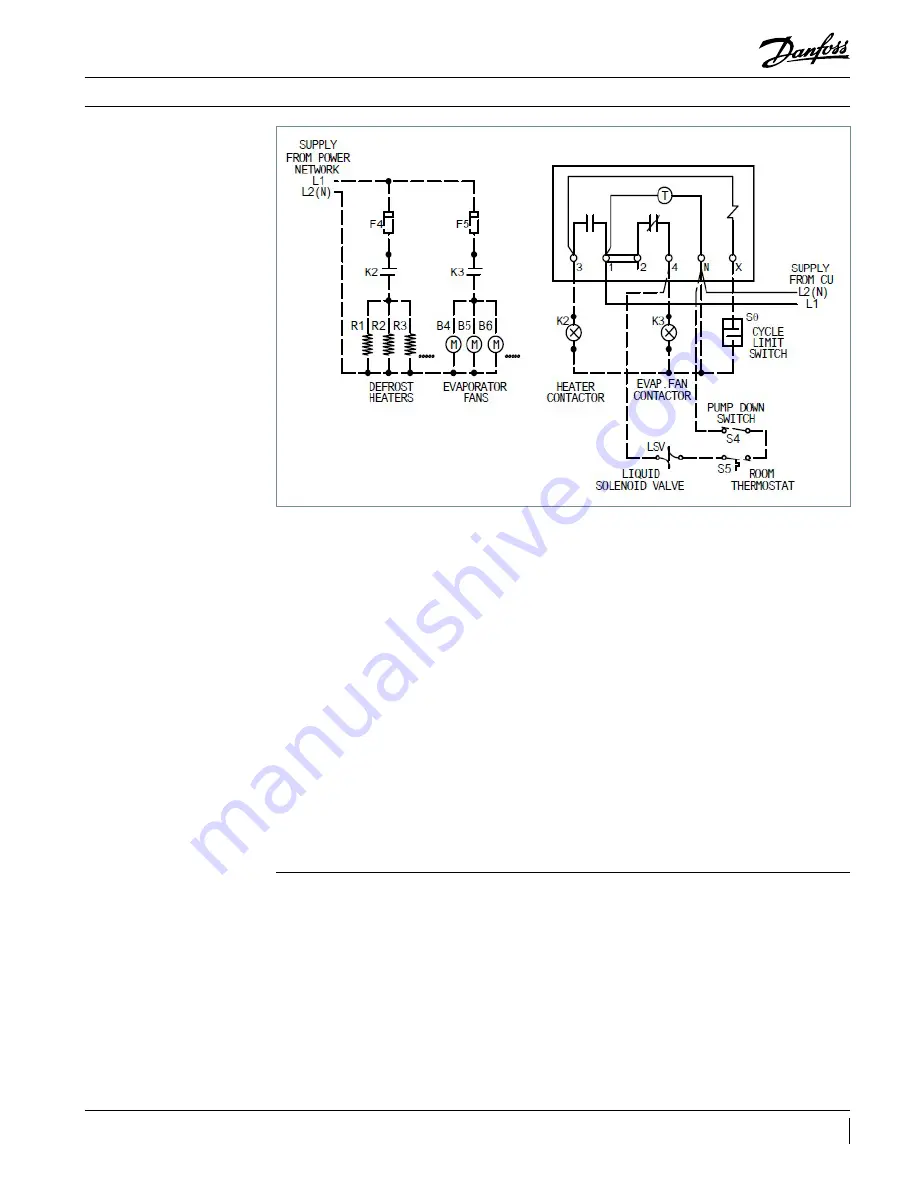

Sequence of operation – Field wiring

Sequence of operation

Refrigeration Cycle

1. Defrost timer is powered by the condensing

unit, connecting the supply to terminal “1” and

“N”.

2. The fan delay and the defrost termination

thermostat is closed in the fan delay position

and open in the defrost termination position.

The evaporator fan(s) run continuously.

3. The defrost heaters are off during refrigeration

cycle.

4. The room thermostat closes when the

temperature rises above the desired setting.

5. The liquid line solenoid valve(LSV) gets

energized and opens to allow the liquid

refrigerant to flow through the evaporator.

6. The low-pressure control switch closes when the

suction pressure rises above the cut-in setting.

7. The compressor contactor gets energized and

supply power to allow the compressor and

condenser fan to run.

8. The room temperature gradually decreases to

the desired temperature.

9. Once the desired temperature is attained, the

thermostat opens and the liquid line solenoid

closes, it will in turn stop the refrigerant flow

through the evaporator.

10. Suction pressure decreases and the

compressor contactor opens when the

pressure drops below the cut-out setting on

the low-pressure control. The compressor and

condenser fan stop running.

11. This cycle is repeated as many times as

necessary to satisfy the room thermostat.

12. Frost may form on the evaporator coil until the

defrost cycle is initiated.

Defrost Cycle

1. The defrost cycle starts automatically by the

timer at predefined intervals. Typical settings

are between two and four defrost cycles per day

for freezers. For heavier frost loads additional

settings may be required.

2. Contacts “2” to “4” opens in the defrost timer and

disconnects the circuit to the room thermostat,

liquid line solenoid, and evaporator fan motors.

This will lead the compressor to pump down

and shut-off. At the same time, Contacts “1”

to “3” closes in the timer and it will allow the

defrost heater to start through the heater

contactor.

3. The defrost heaters rise the temperature of the

coil to 32˚F triggering the frost to melt of the

coil.

4. When the coil temperature rises to 45˚F to 55˚F,

the cycle limit switch closes and it energizes

the Liquid line solenoid valve to allow the

refrigeration cycle to begin again.

Summary of Contents for OP-HJZM

Page 17: ......