© Danfoss A/S (AC-MCI / sw), 2014-11

DKRCC.PS.RQ0.B7.02 /520H8832

9

Manual

Superheat Controller EIM 336

4.

Using external sensor values

In some applications, the suction pressure and/or the refrigerant

temperature on the evaporator outlet, is measured by a system

controller. This is often the case if the suction pressure is used to

trigger low temperature/pressure alarms by the systems main

controller. In these cases the sensors can be omitted from the EIM

336, and the sensor values can be received via modbus instead.

This requires that the systems main controller continuously

transmits these values to the EIM 336. If no new sensor value is

received within 5 seconds of the last transmission, the sensor will

revert to using the physical sensors.

The suction gas temperature S2 and the evaporator pressure

Pe can be set by writing to the registers “ext S2 Temp” and “ext

EvapPress P0” respectively.

Note

that the external evaporator pressure is received in millibar

so 8.4 bar absolute must be sent as 8400.

It is possible to set the S4 temperature as an external sensor value

also, but since this sensor is not used in the superheat regulation,

this has little practical use.

Related parameters:

Symbolic name

PNU

Description

ext EvapPress P0

2643

External evaporator pressure. This value can be used instead of a sensor.

This register must be written at least every 5 second, otherwise the sensor value will be used.

The entered value is in millibar

ext S2 temp

2644

External S2. This value can be used instead of a sensor.

This register must be written at least every 5 second, otherwise the sensor value will be used.

ext S4 air temp.

2646

External S4. This value can be used instead of a sensor. This register must be written at least every 5 second, otherwise the

sensor value will be used.

5.

Configuring the superheat control

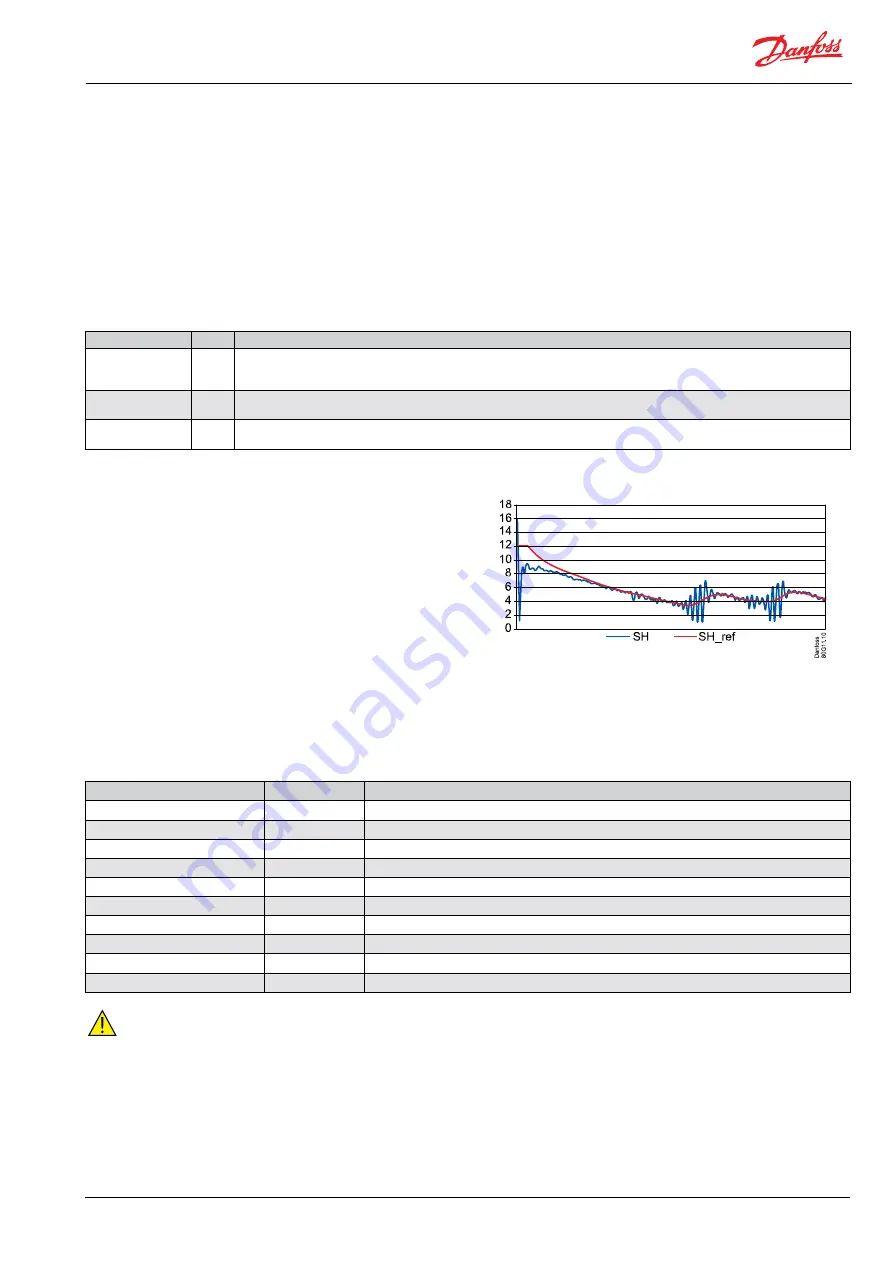

The superheat control algorithm will attempt to regulate the

superheat down to the lowest stable value between the minimum

superheat setting, “n10 Min SH” and the maximum superheat

setting, “n09 Max SH”. If a fixed superheat reference is desired

instead, the “n10 Min SH” and “n09 Max SH” can both be set to

the desired reference value. This will disable the minimum stable

superheat search algorithm and the controller will instead regulate

the superheat according to this reference.

The time constant for the superheat control can be changed by

setting “Tn SH”.

The alpha value is the design time constant and should be in

reasonable proximity to the time constant of the evaporator. A

large alpha means a slow reaction, a small alpha means a fast

reaction.

If the superheat drops below “n22 SH close”, the controller will

close the valve faster to avoid the risk of liquid in the compressors

suction line.

Symbolic name

PNU

Description

n09 Max SH

3015

Maximum superheat reference setting.

n10 Min SH

3021

Minimum superheat reference setting.

n20 Kp T0

3025

Pressure feedback gain.

n22 SH close

3027

Superheat close level. If the superheat goes below this value, the valve will close faster.

--- Tn SH

3103

Integration time for superheat control

--- Alpha

3111

Design time constant. A large alpha means a slow response, a small alpha mean a fast response.

--- Max SH shdw

64301

Copy of 3015. If it is required to write n09 frequently, this should be used instead.

--- Min SH shdw

64302

Copy of 3021. If it is required to write n10 frequently, this should be used instead.

--- Tn SH shdw

64303

Copy of 3103. If it is required to write TnSH frequently, this should be used instead.

--- Alpha shdw

64304

Copy of 3111. If it is required to write alpha frequently, this should be used instead.

Note:

Main Switch r12 should be ON to start the regulation. This can also be

accomplished with the external hardware mainswitch.

See appendix 1 for details.