8

DKRCC.PS.RQ0.B7.02 /520H8832

© Danfoss A/S (AC-MCI / sw), 2014-11

Manual

Superheat Controller EIM 336

Operation

1.

Selecting a refrigerant

The controller needs to know which refrigerant is used in order to

accurately control the superheat. This can be selected by setting

the “o30 Refrigerant” to the desired refrigerant as defined in the list

below.

If no refrigerant is selected (“o30 Refrigerant” is set to 0 or an

undefined refrigerant), the “No Rfg. Sel.” alarm is set and the

controller will not start regulating.

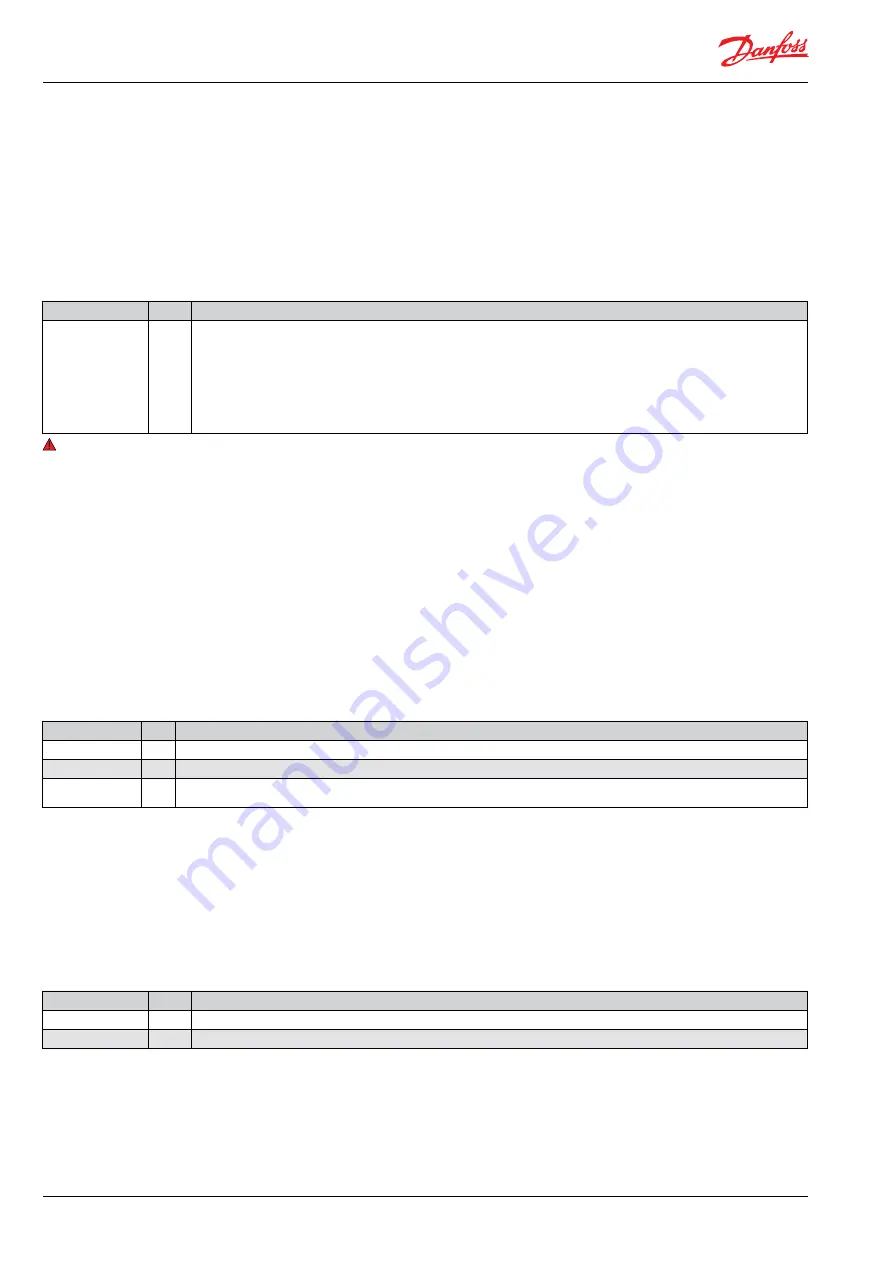

Refrigerant setting

Before refrigeration can be started , the refrirant has to be defined.

You can select the following refrigerant.

Related parameters:

Symbolic name

PNU

Description

o30 Refrigerant

2551

1 = R12

2 = R22

3 = R134a

4 = R502

5 = R717

6 = R13

7 = R13b1

8 = R23

9 = R500

10 = R503

11 = R114

12 = R142b

13 = User defined

14 = R32

15 = R227

16 = R401A

17 = R507

18 = R402A

19 = R404A

20 = R407C

21 = R407A

22 = R407B

23 = R410A

24 = R170

25 = R290

26 = R600

27 = R600a

28 = R744

29 = R1270

30 = R417A

31 = R422A

32=R413A

33=R422D

34=427A

35=R438A

R36=Opteon

XP10

37 =R407F

Warning: Wrong selection of refrigerant may caurse damage to the compressor.

2.

Connecting and setting up a valve

The EIM 336 controller is designed to be used with Danfoss

ETS 6 valves with a maximum of 480 pulses from fully closed to

fully open. This setting should not be changed.

The speed of the valve can be changed by increasing or

decreasing the number of pulses per second, “n38 Max StepsSec”.

A larger value will make the value open or close faster. Note that

the torque of a stepper motor decreases as the speed increases.

Too high speeds should therefore be avoided. For the ETS 6 valve,

the recommended speed setting is 31 pulses per second.

When the controller is powered, the valve will first be closed

fully so that the controller starts from a known opening degree

(0%). In order to make sure that it is fully closed, the valve will be

closed 100% plus an additional contribution known as backlash.

The backlash takes into account that the stepper motor may

loose some steps due to too low torque or mechanical slippage

in the gears etc. The start backlash is the amount of extra steps in

percent to close once the valve is closed (less than 1%). If the valve

is opening and reaches its destination, it will move additional steps

in the opening direction, then move the same amount of steps in

the closing direction. This is called backlash and is the amount of

steps to add to compensate for spindle play.

Related parameters:

Symbolic name

PNU Description

n38 Max StepsSec 3033 Steps per second

n39 Start BckLsh

3034 Backlash, is the additional amount of steps, in percent, to close at startup and when the valve opening degree is less than 1%.

n40 Backlash

3035 Start Backlash is the amount of steps to compensate for spindle play

3.

Connecting and setting up a pressure sensor

The pressure sensor input is setup by default to accept an AKS32R

pressure transducer. If another sensor is to be used, it is important

to note that it needs to be a 0.5 - 4.5 V d.c. ratiometric type (10% -

90% of supply voltage).

The default range for the sensor is 0 to 16 bar absolute. Thi s

can be changed by setting the minimum transducer pressure,

“o20 MinTransPres” and the maximum transducer pressure, “o21

MaxTransPres” to the new values. The values must be entered in

bar absolute so a sensor with a range of -1 to 12 bar gauge, needs

to be entered as 0 to 13 bar absolute.

Related parameters:

Symbolic name

PNU

Description

o20 MinTransPres

2034

Minimum transducer pressure (in bar absolute x 10)

o21 MaxTransPres

2033

Maximum transducer pressure (in bar absolute x 10)