8 | © Danfoss | 2019.02

VI.GM.A2.02

CCR3+ Controller

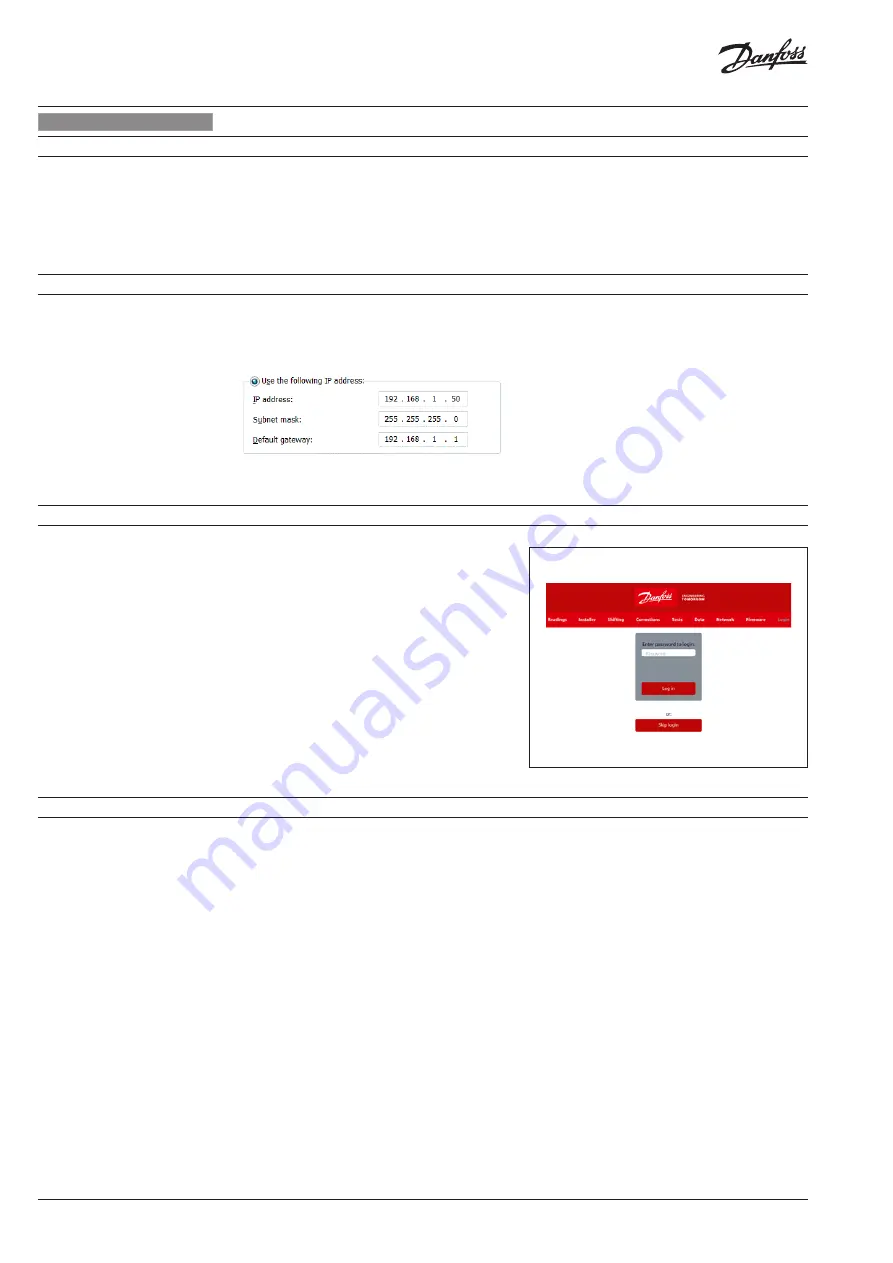

1. Enter »Local Network settings«

2. Go to »Properties« -> »Internet Protocol

Version 4 (TCP/IPv4)

3. Configure IP address:

4. Confirm with »OK« and close menu in PC.

ENGLISH

8. Wi-Fi settings

(no cable needed - recommended for all types of devices)

9. Local Network settings

(only for LAN cable connection with PC)

10. Run CCR3+ application

11. CCR3+ Dashboard (Web App Screen)

1. Switch on Wi-Fi

2. Scan for Wireless Network Connection

3. Select CCR WI-Fi network

4. Enter password (default is »admin1234«)

5. Connect

Launch your browser from a computer or

wireless device that is connected to the CCR3+.

Tap the IP address into web browser window:

1. Wi-FI access: Type 192.168.1.10 into Web

Browser

2. LAN connection: Type 192.168.1.100 into Web

Browser

CCR3+ application will open.

For 1st login enter password »

admin1234

«

Important:

Change of password to secure any

unauthorized interaction from 3rd parties.

Note:

You can Skip login for access to data only

in CCR3+ (reading, overview only).

When the setup and is complete, the reading

display will be shown on the screen.

The CCR3+ App screen has a dashboard that

offer plenty of status overview, basic and

advanced settings. The manufacturer reserves

the right to change Firmware in production to

improve handling and functionality. An up - to

- date list of settings for the given firmware is

available on the Danfoss website.

New settings can automatically upgrade

according to guidelines in instruction.

•

Readings:

Informations about basic settings,

device status, current time and date, storage

capacity

•

Installer:

Advanced and service settings

•

Shifting:

Shift return temperature

•

Corrections:

Temperature sensor calibration

settings

•

Tests:

Device outputs testing tool

•

Data:

Access to Data log file

•

Network:

BMS and IP/TPC settings

•

Firmware:

Firmware upgrade tool

•

Login:

Login option