Cascade Controller Option

Description of choice:

Set the desired feedback minimum within the

programmed minimum and maximum in Quick Menu

items 14 and 15. The process unit is selected in

Quick menu item 13,

Process Units

.

NB!:

Factory setting is for a single 4 - 20 mA current

signal transmitter for process feedback. In

all other cases, see instructions in Chapter

10,

Feedback Transmitter Wiring

.

Quick Menu 029 Par. 419 Setpoint 2

(SETPOINT 2)

Value:

Feedback Min. to Feedback Max.

✭

0.000

Function:

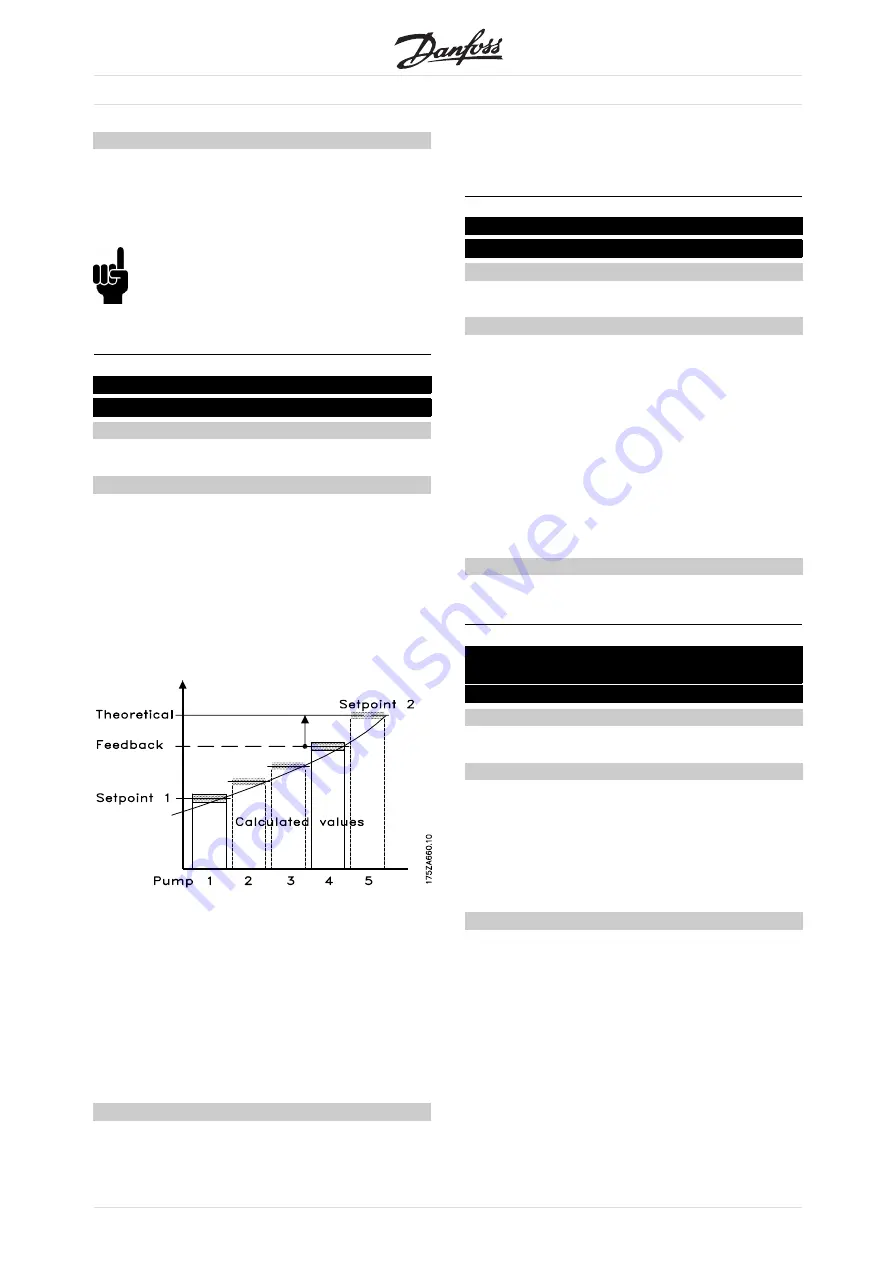

The default feedback process is used when a pressure

feedback signal is measured at the outlet of the

pumps. The cascade controller uses the feedback to

estimate the setpoint required at various rates of flow.

Setpoint 2 is the maximum pressure required when

the system is running with all pumps at full capacity. A

theoretical value calculates pressure loss in the system

under maximum load. The controller adjusts the

loading based upon the number of pumps in operation.

The range is determined by Quick Menu item 14

(parameter 413,

Minimum Feedback

) and Quick Menu

item 15 (parameter 414,

Maximum Feedback

).

When the pressure feedback signal originates at

the far end of the system, the drive does not

need to compensate for system pressure changes

due to flow. For this system configuration, or

for two setpoint PID control, see

Alternative

Programming

at the end of this chapter.

Description of choice:

Set the desired feedback maximum within the

programmed minimum and maximum in Quick Menu

items 14 and 15. The process unit is selected in

Quick menu item 13,

Process Units

.

Quick Menu 031 Par. 722 Pump cycling

(PUMP CYCLING)

Value:

Enabled - Disabled

✭

Enabled

Function:

To achieve equal hours of operation, use of pumps

or fans can be cycled. Timers on the relay outputs

(relays 6, 7, 8, and 9) monitor the running hours of

each pump. In staging on, the relay with the least

hours is switched on. In destaging, the relay with the

most hours is switched off. Not operating a pump

over long time periods can create corrosion concerns.

If cycling is disabled, the controller follows the fixed

pattern of relay activation (6, 7, 8 and 9) regardless of

the running hours. Destaging is in the reverse order.

Description of choice:

Choose whether to enable or disable the function.

Quick Menu 032 Par. 319 Analog output,

terminal 42

(AO 42 FUNCTION)

Value:

Output, terminal 42

✭

Output current 4-20 mA

Function:

An analog/digital output is available through terminal

42 and can be programmed to show a status or an

analog value such as frequency. For the analog output,

there are three types of output signals: 0 to 20 mA, 4

to 20 mA, or 0 to 32000 pulses. The pulse rate is set

by parameter 320,

Terminal 42, Output, Pulse Scaling

.

Description of choice:

Set the output of terminal 42 to

Output Frequency

(pulse sequence)

, (OUT.FREQ.PULSE) for Master/Slave

operation as shown in the wiring diagram in Chapter

4. Using frequency pulse is a reliable way of providing

the same speed reference to all slave drives. Current

output is limited to two slave drives.

System pressure and flow requirements can often be

generated using parallel pumps at different efficiencies.

The cascade controller can automatically configure

the number of pumps in operation to achieve the

highest system efficiency. Running three pumps at full

MG.60.I3.02 - VLT is a registered Danfoss trademark

48