55

Installation Guide

AME 130(H), AME 140(H)

Danfoss Heating

VI.KU.M4.90

DH-SMT/SI

ENGLISH

Safety Note

To avoid injury and damage to persons and

devices, it is absolutely necessary these

instructions are carefully read and observed

prior to assembly and commissioning.

Necessary assembly, start-up, and

maintenance work must be performed

only by qualified, trained and authorised

personnel.

Prior to assembly and maintenance work on

the controller, the system must be:

- depressurised

- cooled down

- emptied and

- cleaned

Please comply with the instructions of the

system manufacturer or system operator.

Do not remove the cover before

the power supply is fully

switched off.

Disposal instruction

This product should be

dismantled and its

components sorted, if

possible, in various groups

before recycling or disposal.

Always follow the local disposal

regulations.

Mounting

➊

The actuator should be mounted with the

valve stem in either horizontal position or

pointing upwards.

The actuator is fixed to the valve body by

means of a ribbed nut which requires no

tools for mounting. The ribbed nut should be

tightened by hand.

Installation

❷

1. Check the valve neck. The actuator should

be in steam up position (factory setting).

Ensure that the actuator is mounted

securely on the valve body

2. Wire the actuator according to the wiring

diagram

3 The direction of stem movement can be

observed on the position indicator

①

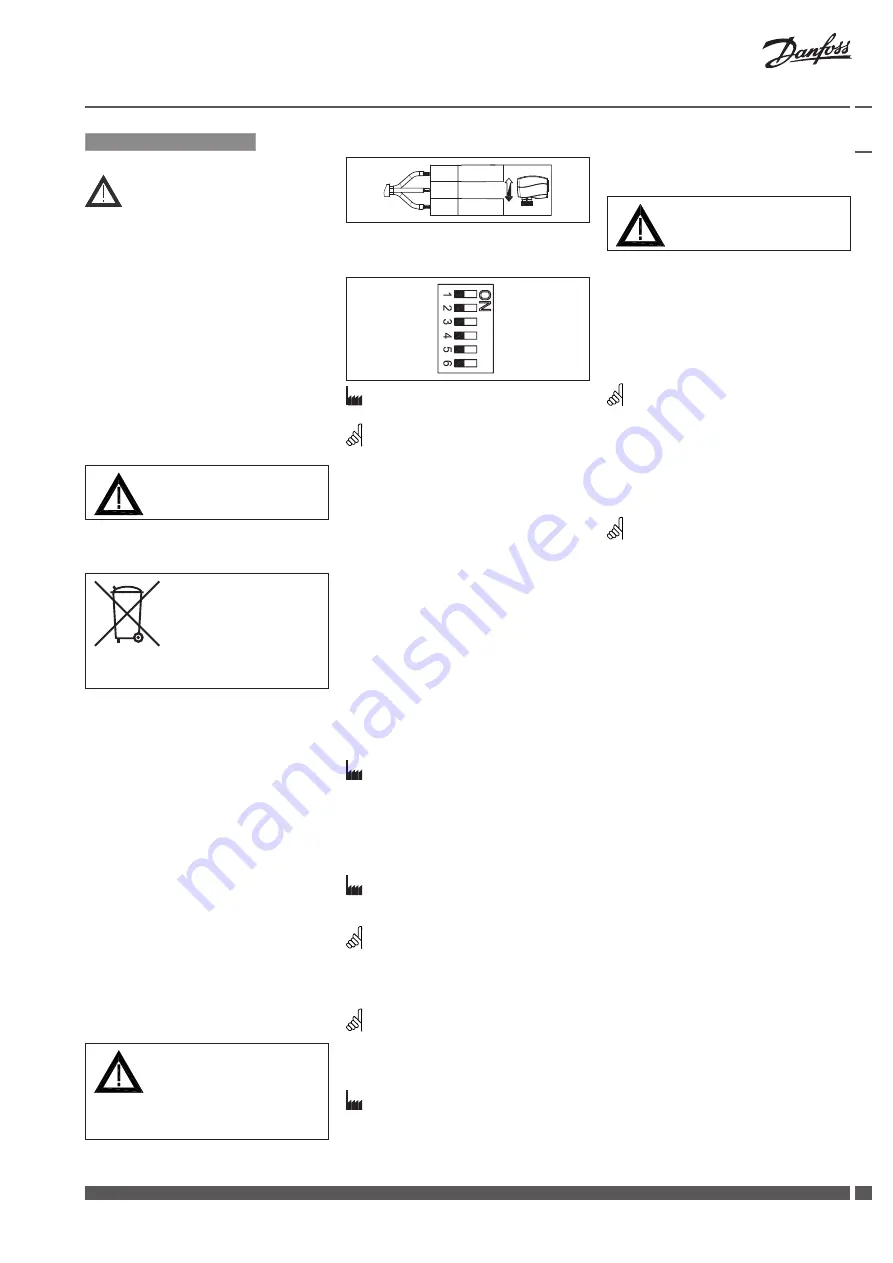

Wiring

❸

Do not touch anything on the

PCB! Switch off the power line

before wiring the actuator!

Lethal voltage!

Wire the actuator according to the

wiring diagram.

Red

Gray

Black

24 VAC

Y 0 - 10 VDC

Common

DIP switch settings

Reset

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

Reset

2V…---V

Direct

- - -

0(2)…5(6) V

U

Reset

2 V...---V

0V...---V

Direct

Inverse

---

Sequential

0(2)...5(6)V

5(6)...10V

U

I

Factory settings:

ALL switches are on OFF position!

NOTE:

All combinations of DIP switches are allowed.

All functions that are selected are added

consecutively.

SW1: Reset

❹

After the actuator has been connected to

power supply, the actuator will start the self-

adjustment procedure. The indicator LED

①

flashes until self adjustment is finished. The

duration depends on the spindle travel and

will normally last a few minutes. The stroke

length of the valve is stored in the memory

after self adjustment has been completed. To

restart self adjustment, change the position

of the RESET switch (switch No.1). If the

supply voltage is switched off or falls below

80 % in more than 0.1 s, the current valve

position will be stored in the memory and all

data remain saved in the memory also after a

power supply cut-out.

SW2: 2-10 V/0-10 V

❺

Factory setting is:

2-10 V.

SW3: Direct/Inverse

❻

The actuator can be set for the spindle to

travel downwards on the rising control signal

(DIRECT), OR for the spindle to travel upwards

on the rising control signal (INVERSE)

Factory setting is:

DIRECT

SW4: ---/Sequential

❼

NOTE:

This combination works in combination with

switch No.5: 0(2)-5(6) V/5(6)-10 V.

SW5: 0(2)-5(6) V/5(6)-10 V

❽

NOTE:

This function is available if switch No.4: ---/

Sequential is set.

SW6: U/I

❾

Factory setting:

voltage control signal (2-10 V).

Manual override

(for service purposes only)

Do not manually operate the

drive under power!

AME 130, AME 140

❿

①

Remove the cover

②

Insert the Allen key 6 into the spindle

③

Press and hold the button (on the bottom

side of the actuator) during manual

override

④

Pull out the tool

⑤

Replace cover

Remark:

A ‘click’ sound after energising the actuator

means that the gear wheel has jumped into

normal position.

AME 130H, AME 140H

⓫

Press and hold the button

①

(on the bottom

side of the actuator) during manual override.

Remark:

A ‘click’ sound after energising the actuator

means that the gear wheel has jumped into

normal position.

Function test

The light emitting diode (LED)

❹①

indicates

whether the actuator is in operation or not,

the operating status, and failures, if any.

• No light

- no operation or no power supply

• Constant light

- normal operation

• Flashing light (1 Hz)

- self-adjusting mode

• Flashing light (~ 3 Hz):

- power supply too low

- initial self-adjusting time to short

due too short valve’s stroke must

last more than 12 sec.