13

English

Note

If moisture might enter the piping, follow belows.

(I.e., if doing work during the rainy season, if the actual work

takes long enough that condensation may form on the inside of

the pipes, if rain might enter the pipes during work, etc.)

(1) After performing the vacuum drying for two hours, pressurize to

0.05 MPa (i.e., vacuum breakdown) with nitrogen gas, then

depressurize down to –100.7 kPa for an hour using the vacuum

pump (vacuum drying).

(2) If the pressure does not reach –100.7 kPa even after depressur-

izing for at least two hours, repeat the vacuum breakdown - vac-

uum drying process.

After vacuum drying, maintain the vacuum for an hour and make sure

the pressure does not rise by monitoring with a vacuum gauge.

9.

PIPE INSULATION

•

Insulation of pipes should be done after performing “

8. AIR TIGHT

TEST AND VACUUM DRYING

”.

•

Always insulate the liquid side piping and gas side piping in the

interunit piping and refrigerant branching kit. Failing to insulate

the pipes could cause leaking or burns. (The gas side piping can

reach temperatures of 120°C. Be sure the insulation used can

withstand such temperatures.)

•

Reinforce the insulation on the refrigerant piping according to the

installation environment. Condensation might form on the surface

of the insulation.

Ambient temperature: 30°C, humidity: 75% to 80% RH: min.

thickness: 15 mm.

If the ambient temperature exceeds 30°C and the humidity

80% RH, then the min. thickness is 20 mm.

•

If there is a possibility that condensation on the shutoff valve

might drip down into the indoor unit through gaps in the insulation

and piping because the outdoor unit is located higher than the

indoor unit, etc., this must be prevented by caulking the connec-

tions, etc.

(Refer to figure 29)

•

The piping lead-out hole lid should be attached after opening a

knock hole.

(Refer to figure 30)

•

If small animals and the like might enter the unit through the pip-

ing lead-out hole, close the hole with blocking material (procured

on site) after completion of “

11. ADDITIONAL REFRIGERANT

CHARGE AND CHECK OPERATION

”.

(Refer to figure 30)

(Refer to figure 29)

1.

Liquid side shutoff valve

2.

Gas side shutoff valve

3.

Indoor interunit piping

4.

Insulation material

5.

Coking, etc.

6.

Refrigerant charge port

(Refer to figure 30)

1.

Piping lead-out hole lid

2.

Open a knock hole at “

”.

3.

Block “

”.

4.

Liquid side piping

5.

Gas side piping

Note

•

After knocking out the holes, we recommend you remove burrs in

the knock holes (see figure 30) and paint the edges and areas

around the edges using the repair paint.

10. CHECKING OF DEVICE AND INSTAL-

LATION CONDITIONS

Be sure to check the followings.

For those doing electrical work

1.

Make sure there is no faulty transmission wiring or loosing of a

nut.

See “

7-4 Transmission Wiring Connection Procedure

”.

2.

Make sure there is no faulty power wiring or loosing of a nut.

See “

7-5 Power Wiring Connection Procedure

”.

3.

Has the insulation of the main power circuit deteriorated?

Measure the insulation and check the insulation is above regular

value in accordance with relevant local and national regulations.

For those doing pipe work

1.

Make sure piping size is correct.

See “

6-1 Selection of piping material and Refrigerant branch-

ing kit

”.

2.

Make sure insulation work is done.

See “

9. PIPE INSULATION”

.

3.

Make sure there is no faulty refrigerant piping.

See “

6. REFRIGERANT PIPING

”.

11. ADDITIONAL REFRIGERANT

CHARGE AND CHECK OPERATION

The outdoor unit is charged with refrigerant when shipped from the

factory, but depending on the size and length of the piping when

installed, it may require additional charging.

For charging the additional refrigerant, follow the procedure in this

chapter.

And then carry out the check operation.

11-1 Before working

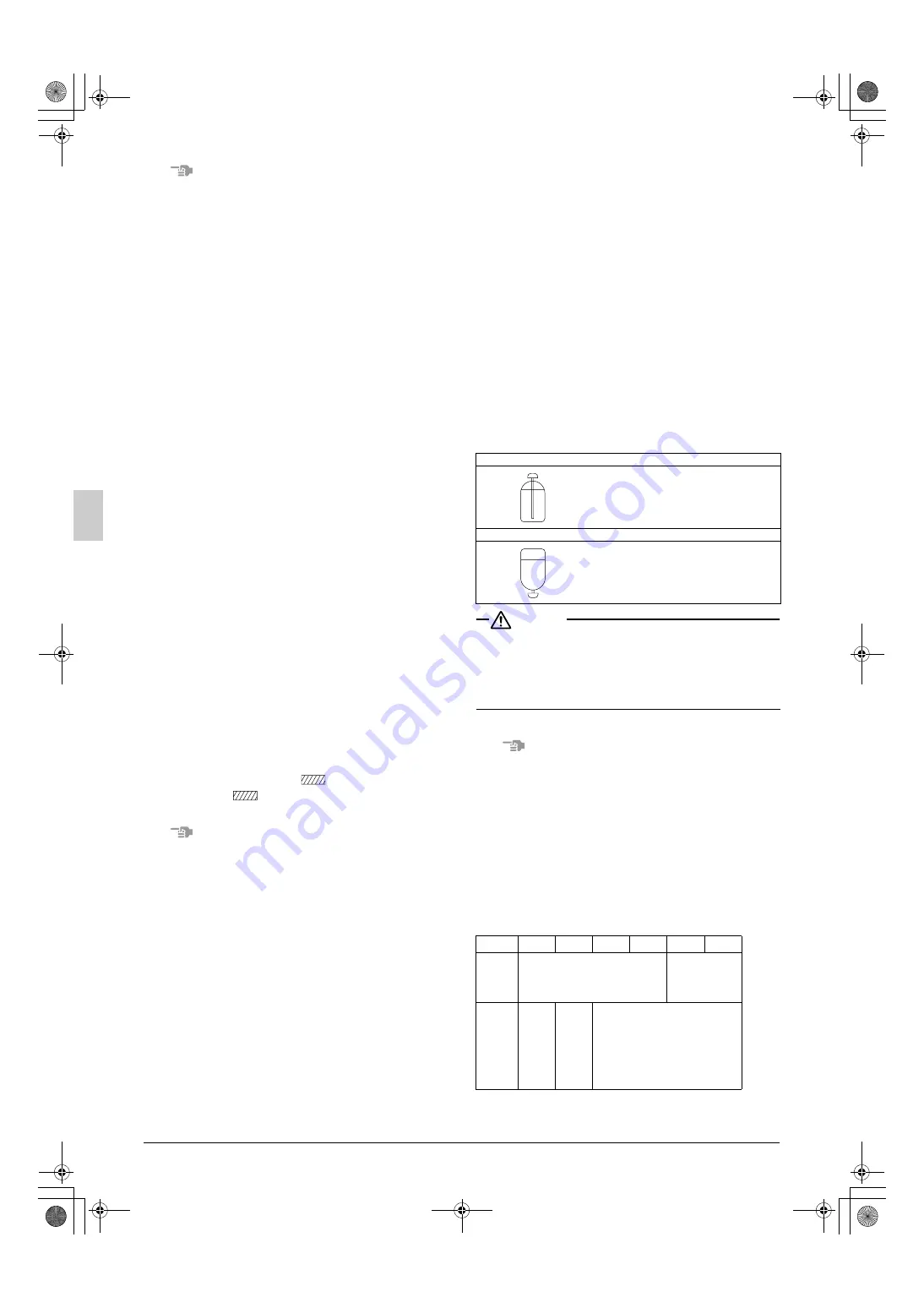

[About the refrigerant tank]

Check whether the tank has a siphon pipe before charging and place

the tank so that the refrigerant is charged in liquid form. (See the fig-

ure below.)

CAUTION

• Always use the proper refrigerant (R410A). If charged with the

refrigerant containing an improper material, it may cause an

explosion or accident.

•

R410A is a mixed refrigerant, so charging it as a gas will cause

the refrigerant composition to change, which may prevent normal

operation.

[Shutoff valve operation procedure]

When operating the shutoff valve, follow the procedure instructed below.

Note

•

Do not open the shutoff valve until “10. CHECKING OF DEVICE

AND INSTALLATION CONDITIONS” are completed. If the shutoff

valve is left open without turning on the power, it may cause refrig-

erant to buildup in the compressor, leading insulation degrada-

tion.

•

Be sure to use the correct tools.

The shutoff valve is not a back-seat type. If forced it to open, it

might break the valve body.

•

When using a service port, use the charge hose.

•

After tightening the cap, make sure no refrigerant gas is leaking.

[Tightening torque]

The sizes of the shutoff valves on each model and the tightening

torque for each size are listed in the table below.

<Size of Shutoff Valve>

With siphon pipe

Other tanks

Q8 type

Q10 type

Q12 type

Q14 type

Q16 type

Liquid

side shut-

off valve

φ

9.5

The Q12 type corresponds to the

12.7-diameter onsite piping using

the included piping.

φ

12.7

Gas side

shutoff

valve

φ

15.9

φ

19.1

φ

25.4

The Q10 type corresponds to the

22.2-diameter onsite piping using

the accessory pipe.

The Q12 ~ 16 type corresponds to

the 28.6-diameter onsite piping

using the accessory pipe.

Stand the tank upright and charge.

(The siphon pipe goes all the way inside,

so the tank does not need be put

upside-down charge in liquid form.)

Stand the tank upside-down and charge.

01_EN_3P226891-13Q.fm Page 13 Thursday, December 2, 2010 10:15 AM