I

nsTallaTIon

and

a

pplICaTIon

C

onsIderaTIons

www.DaikinApplied.com 11

IOM 1264-1 • NAVIGATOR

®

MODEL WWV CHILLERS

Table 3: Glycol Performance Factors

%

Freeze Point

Flow

Pressure

Drop

°

F

°

C

Ethylene Glycol

10

26

-3.3

1.028

1.090

20

18

-7.8

1.059

1.216

30

7

-14

1.094

1.379

40

-7

-22

1.132

1.557

50

-28

-33

1.174

1.811

Propylene Glycol

10

26

-3.3

1.011

1.025

20

19

-7.2

1.030

1.150

30

9

-13

1.056

1.375

40

-5

-21

1.090

1.701

50

-27

-33

1.131

2.128

Ice Mode

Ice making chillers will run very cold fluid during off hours,

when energy is least expensive, to build a tank of ice. In ice

building mode, the unit will operate at full load until the shutoff

temperature setpoint is reached. Optional double evaporator

insulation is recommended for ice mode operation. The

standard controller software will require “ice” setpoint changes

and a digital signal into the controller is required to change to

the ice mode and back to standard cooling. Set points related

to ice mode can be found in

See Unit Level Set Points on page

21

and wiring connection points are shown in

Figure 10 on

page 14

.

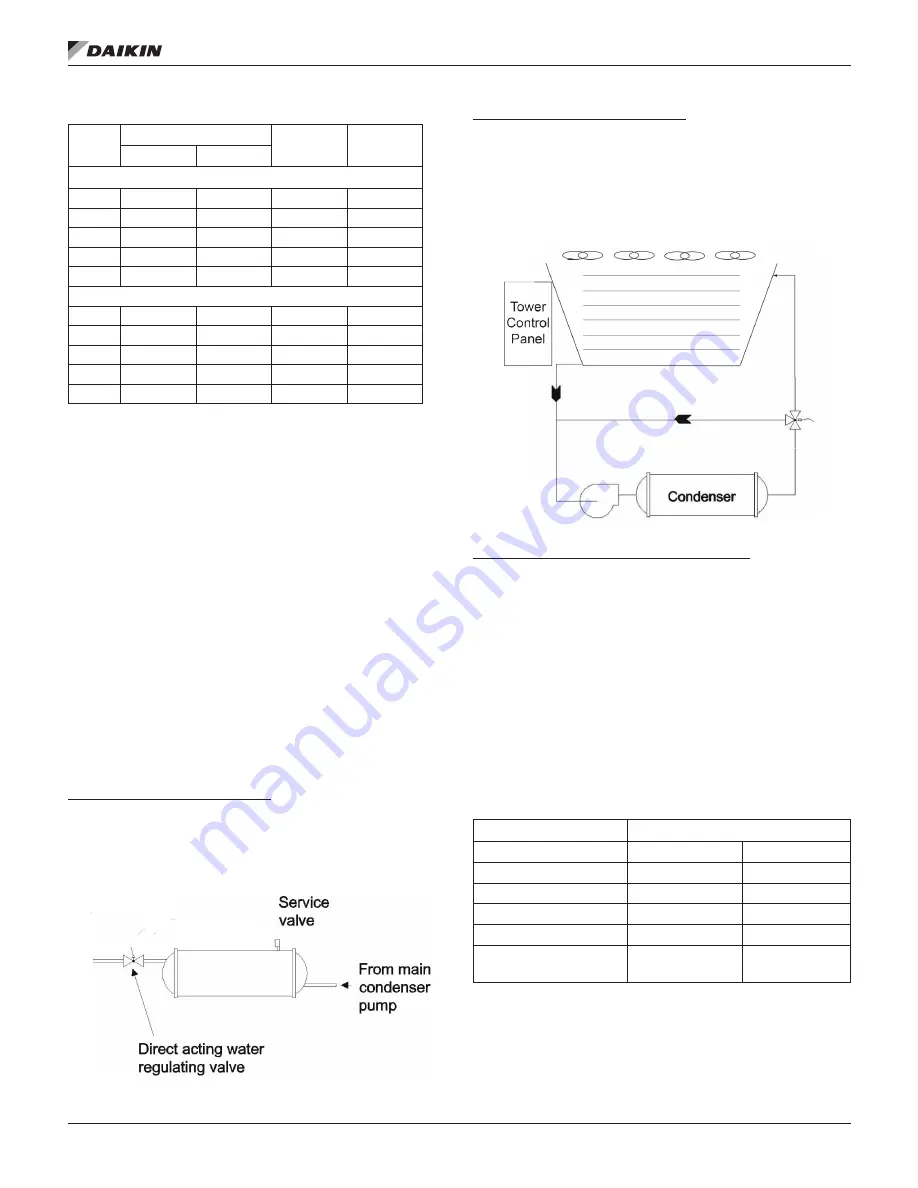

Condenser Water Control

The minimum condenser inlet water temperature should not

be less than 60°F (15.6°C). If the water temperature is lower,

a method of condenser water temperature control will be

required. Cooling tower control is discussed beginning on

page

28.

Two-Way Bypass Valve Operation: A two-way regulating

control valve can control flow to ensure adequated condenser

water temperature. The unit controller can send a 0-10Vdc

signal to the valve to modulate its position.

Figure 4: Water Tower Connections - 2-Way Valve

Three-Way Bypass Valve Operation: To modulate the water

temperature in the condenser, install a three-way by-pass

valve.

Figure 5

shows how the three-way valve is applied in

the condenser water system. The three-way valve position can

be modulated by a 0-10Vdc signal from the unit controller to

regulates proper water temperature.

Figure 5: Water Tower Connections - 3-Way Valve

VFD Operating with a Condenser Water Pump: In place of a

valve, use a circulation pump controlled by an inverter.

The VFD speed may be controlled by an analog 0-10

Vdc signal issued by the controller according to the water

temperature entering the condenser.

Relief Valves

As a safety precaution and to meet code requirements, each

chiller is equipped with pressure relief valves located on the

condenser, evaporator, and compressor suction line(s) for the

purpose of relieving excessive refrigerant pressure (caused by

equipment malfunction, fire, etc.) to the atmosphere.

Table 4: Three-Way Relief Valve Data

Chiller

WWV

Relief Valve

Evaporator

Condenser

Location

Top of vessel

Top of vessel

Pressure Setting (psi)

225

300

Discharge Cap.(lb/min air) 84.4

111

Qty

1 set

1 set

Connection Size

1.0-inch female

NPT

1.0-inch female

NPT

Building codes require that relief valves be vented to the

outside of a building. Relief piping connections to the relief

valves must have flexible connectors.

Remove plastic shipping plugs (if installed) from the inside of

the valves prior to making pipe connections. Whenever vent

piping is installed, the lines must be in accordance with local

Summary of Contents for Navigator WWV

Page 4: ......