48

Step 5: Perform a trial run

To commission the machine it is necessary (tick "

√

" the operations completed):

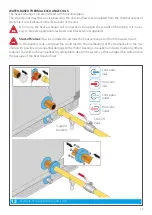

Check the proper connection of the fluid inlet and outlet piping to the thermal (if present) ex-

change coils (if present).

Vent the air from the heat exchange coils.

Check that there is a suitable siphon for all the water being drained.

Inspect the correct installation and adequate electrical connection of the energy recovery equip-

ment, together with a mechanical and electrical check.

Insert an anti-vibration coupling between the machine and the ducts.

Check the tightening of screws and bolts (especially those used to attach motors and fans).

Check the integrity of the anti-vibration supports and the various accessories.

Remove extraneous materials (e.g., assembly sheets, tools, clips, etc.) and dirt (footprints, dust, etc.)

from inside the sections.

Summary of Contents for Modular Rotary

Page 15: ...15 Notes...

Page 28: ...28 Notes...

Page 33: ...33 VDI 6022 6...

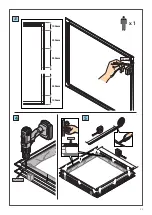

Page 34: ...34 1 x TE8x35 1 x 8 5 1 x M8 2 x TE8x35 2 x 8 5 2 x M8 7...

Page 43: ...43 3 4 5 x 1 100mm 100mm 250mm 250mm 250mm 10 100mm 5mm...

Page 44: ...44 6 7 NO OK...

Page 45: ...45 H2O SOAP 8...

Page 46: ...46 9...

Page 47: ...47 Notes...

Page 62: ...62 Repair log DATE SERVICE TYPE TIME REQUIRED SIGNATURE...