37

9

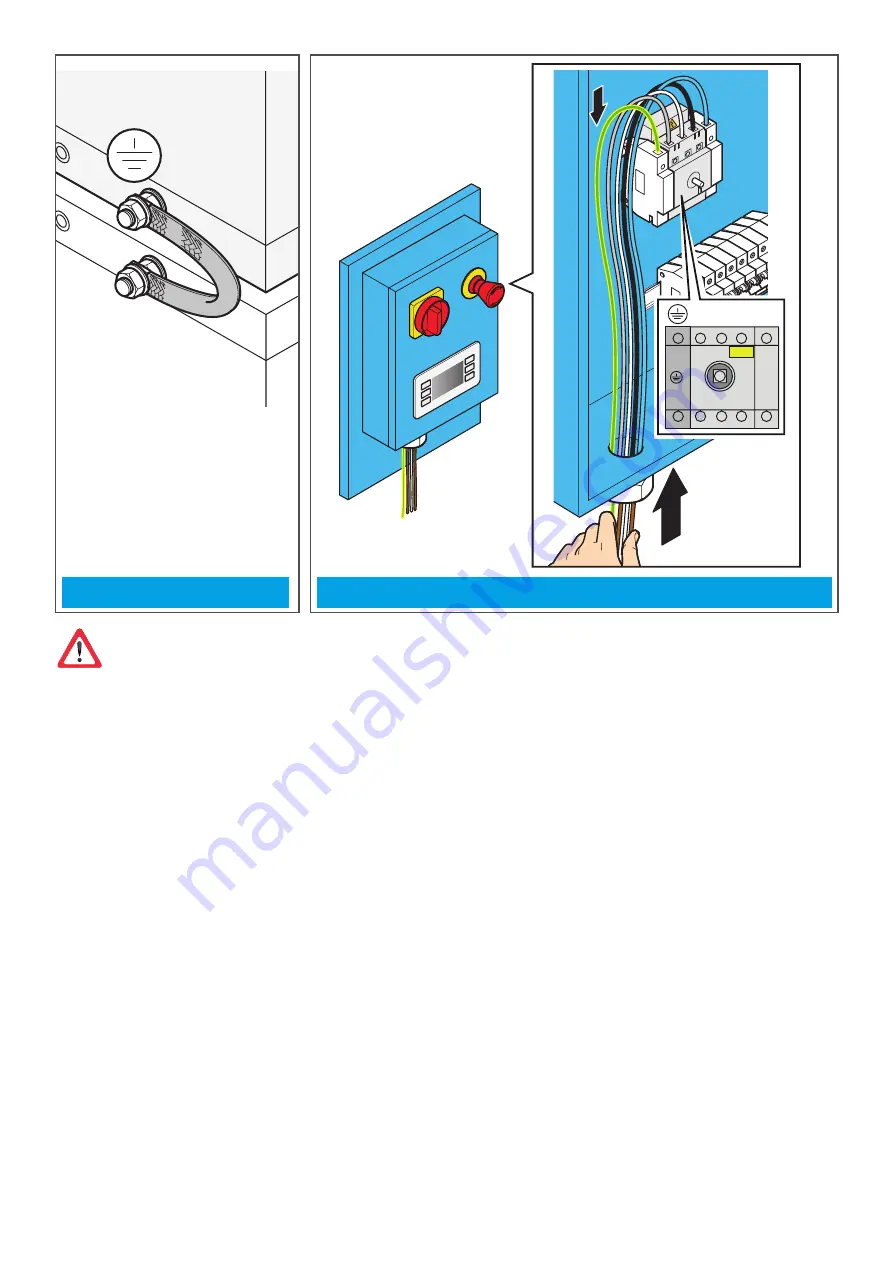

Grounding

QS1

L1 L2 L3 N

10

Example of electrical connection

Additional warnings regarding the connection to the power supply:

It is necessary to install a suitable differential-type protection upstream of the machine's power supply

connection points, in order to be able to isolate each of its elements in the event of malfunctions; the

choice of the differential protection device must not be in conflict with the provisions of the law, the local

regulations, the characteristics of the plant’s electrical system and of the machine itself.

They are recommended, where not in contrast with local laws or system characteristics, differential switch-

es with adjustable current and trip time that cannot be affected by high frequency. The cables connecting

the various elements of the machine to the power supply must be shielded or must pass through metal

ducting, so as to reduce electromagnetic interference.

The shield or metal ducting must be earthed.

Once the system has been set up, the machine can be connected to the electricity supply network. The

actual supply voltage of the user devices must not deviate more than 10% from the expected normal volt-

age. Higher voltage differences cause damage to users and to the electrical system, malfunctioning of fans,

noise. It is therefore essential to check the compliance of the actual voltage values with the nominal values.

Before connecting the electrical panel, make sure that, during installation and maintenance, no other per-

son besides the one who is working has access to the electrical cabinets or switches.

After connecting, make sure that:

-

The ground c

onnection is sufficient (using the appropriate tool). An incorrect connection, ineffective and lacking the grounding

circuit, is contrary to safety regulations and is a source of danger that can damage the components of the machine.

-

The connections are correct and the current consumption of the motor is lower than indicated on the nameplate.

Size 01 ÷ 02

supply 230/1/50 (V-F-Hz)

Size 03 ÷ 10

supply 400/3/50 (V-F-Hz)

NB: Electric battery module power

supply always 400/3/50 (V-F-Hz)

separate from that of the unit.

Summary of Contents for Modular Rotary

Page 15: ...15 Notes...

Page 28: ...28 Notes...

Page 33: ...33 VDI 6022 6...

Page 34: ...34 1 x TE8x35 1 x 8 5 1 x M8 2 x TE8x35 2 x 8 5 2 x M8 7...

Page 43: ...43 3 4 5 x 1 100mm 100mm 250mm 250mm 250mm 10 100mm 5mm...

Page 44: ...44 6 7 NO OK...

Page 45: ...45 H2O SOAP 8...

Page 46: ...46 9...

Page 47: ...47 Notes...

Page 62: ...62 Repair log DATE SERVICE TYPE TIME REQUIRED SIGNATURE...