13

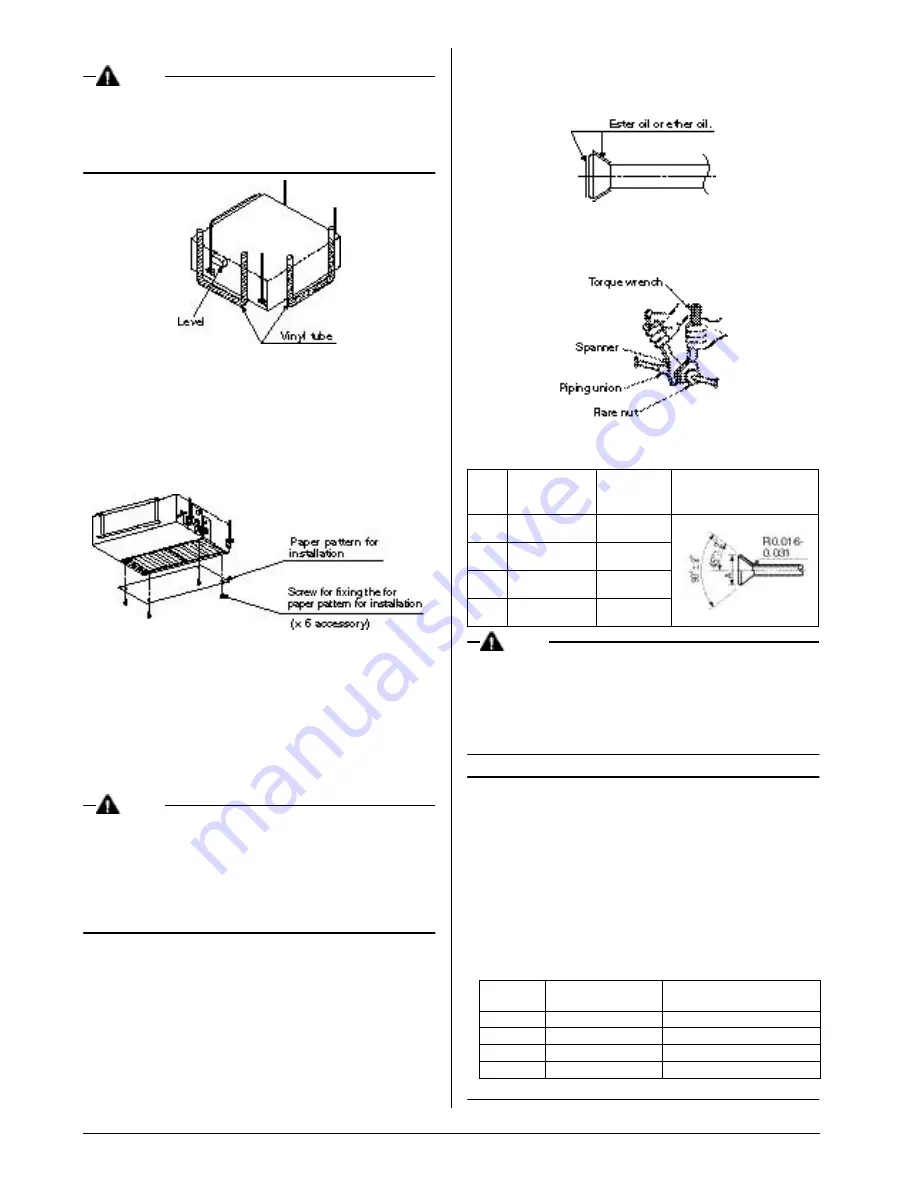

(2) Check the unit is horizontally level.

NOTE

• The indoor unit is equipped with a built-in drain pump

and float switch. At each of the unit’s 4 corners, verify

that it is level by using a level or a water-filled vinyl tube.

(If the unit is inclined against condensate flow, the float

switch may malfunction and cause water to drip.)

(3) Tighten the upper nut.

(4) Fix the paper pattern for installation.

• The paper pattern for installation corresponds with the

measurements of the ceiling opening. Consult the builder

for details.

• Attach the paper pattern for installation to the unit with the

screws as shown in the drawing.

The paper pattern for installation is marked for 3 types of ceil-

ing openings. Read the notations carefully when installing.

6. REFRIGERANT PIPING WORK

6-1

GENERAL INSTRUCTIONS

• For refrigerant piping of outdoor units, see the installation man-

ual attached to the outdoor unit.

• Before refrigerant piping work, check which type of refriger-

ant is used. Proper operation is not possible if the types of

refrigerant are not the same.

• The outdoor unit is charged with refrigerant.

NOTE

• Use a pipe cutter and flare suitable for the type of refrigerant.

• To prevent dust, moisuture or other foreign matter from infil-

trating the tube, either pinch the end or cover it with tape.

• Do not allow anything other than the designated refrigerant

to get mixed into the refrigerant circuit, such as air, etc. If any

refrigerant gas leaks while working on the unit, ventilate the

room thoroughly right away.

6-2

Connecting the refrigerant piping

• When connecting the flare nut, coat the flare both inside and

outside with ester

oil

or

ether

oil and initially tighten by hand 3

or 4 turns before tightening firmly.

• To prevent flare nut cracking and gas leaks, be sure to use

both a spanner and torque wrench together, as shown in the

drawing below, when connecting or disconnecting pipes to/

from the unit.

• Refer to the Table 3 for the dimensions of flare nut spaces.

• Refer to the Table 3 to determine the proper tightening torque.

Table 3

NOTE

• Apply ester oil or ether oil around the flare portions before

connecting.

• The flare nuts used must be those included with the main

body.

• Over-tightening may damage the flare and cause a refriger-

ant leakage.

Not recommendable but in case of emergency

You must use a torque wrench but if you are obliged to

install the unit without a torque wrench, you may

follow the installation method mentioned below.

After the work is finished, make sure to check that

there is no gas leak.

When you keep on tightening the flare nut with a spanner,

there is a point where the tightening torque

suddenly increases. From that position, further tighten the

flare nut the angle shown below:

Table 4

Pipe

size

Tightening torque

(ft.lbf)

Flare

dimensions

A (in.)

Flare shape (in.)

φ

1/4”

10.4 – 12.7

0.342-0.358

φ

3/8”

24.1 – 29.4

0.504-0.520

φ

1/2”

36.5 – 44.5

0.638-0.654

φ

5/8”

45.6 – 55.6

0.760-0.776

Pipe size

Further tightening

angle

Recommended arm length of

tool (in.)

φ

1/4”

60 to 90 degrees

Approx. 5 7/8

φ

3/8”

60 to 90 degrees

Approx. 7 7/8

φ

1/2”

30 to 60 degrees

Approx. 9 13/16

φ

5/8”

30 to 60 degrees

Approx. 11 13/16