6

(4) Tighten the upper nut.

6.

REFRIGERANT PIPING WORK

〈

For refrigerant piping of outdoor units, see the installation

manual attached to the outdoor unit.

〉

〈

Execute heat insulation work completely on both sides of

the gas piping and the liquid piping. Otherwise, a water

leakage can result sometimes.

Use insulation that can withstand temperatures of at least

250°F. Reinforce the insulation on the refrigerant piping

according to the installation environment. If the temperature

above the ceiling might reach 86°F or the humidity RH80%.

Condensation may form on the surface of the insulation.

〉

CAUTION

Follow the points at below.

• Use a pipe cutter and flare suitable for the type of refrigerant.

• Apply ester oil or ether oil to the flare section when using a

flare connection.

• Only use the flare nuts included with the unit. Using different

flare nuts may cause the refrigerant to leak.

• To prevent dust, moisture or other foreign matter from infil-

trating the piping, either pinch the end or cover it with tape.

• Do not allow anything other than the designated refrigerant to

get mixed into the refrigerant circuit, such as air, etc. If any

refrigerant gas leaks while working on the unit, ventilate the

room thoroughly right away.

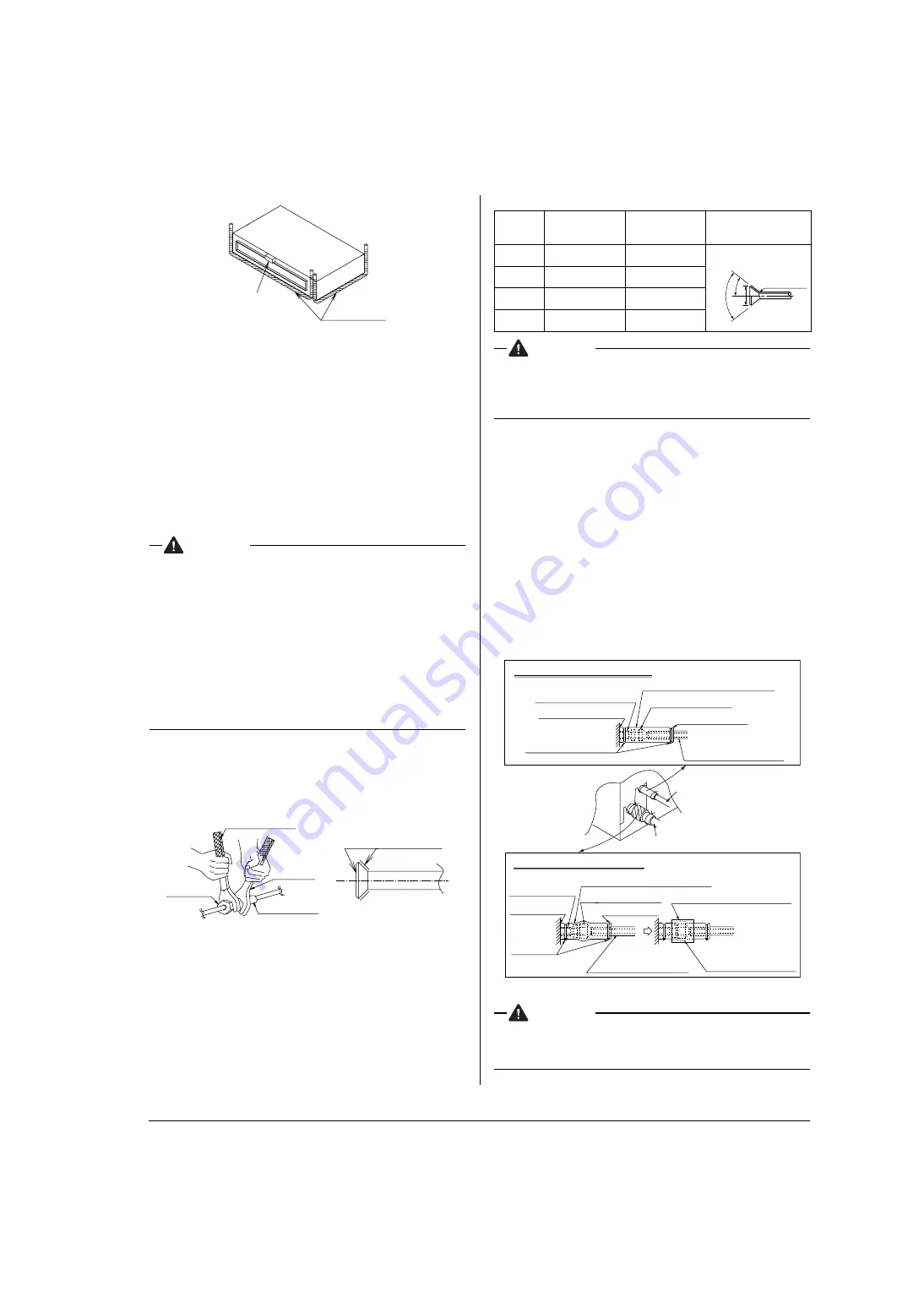

(1) Connect the piping.

• The outdoor unit is charged with refrigerant.

• Be sure to use both a spanner and torque wrench together,

as shown in the drawing, when connecting or disconnecting

pipes to/from the unit.

(Refer to Fig. 6)

• Refer to the Table 1 for the dimensions of flare nut spaces.

• Apply ester oil or ether oil to flare section (both inside and

out) when using flare nut connections and then turn 3 or 4

times by hand.

(Refer to Fig. 7)

• Refer to Table 1 for tightening torque.

Table 1

CAUTION

Overtightening may damage the flare and cause leaks.

Be careful for oil not to adhere to any portions other than

a flare part. If oil adhere to resin parts etc., there is a pos-

sibility of damaging by deterioration.

• Refer to Table 2 if no torque wrench is available.

Using a wrench to tighten flare nuts causes the tightening

torque to suddenly grow much tighter after a certain point.

From there, tighten the nut further by the appropriate angle

listed in Table 2.

(2) After the work is finished, make sure to check that

there is no gas leak.

(3) After checking for gas leaks, be sure to insulate the

pipe connections referring to Fig. 8.

• Insulate using the insulation for fitting (3) (4) included with

the liquid and gas pipes. Besides, make sure the insula-

tion for fitting (3) (4) on the liquid and gas piping has its

seams facing up.

(Tighten both edges with clamp (9).)

• For the gas piping, wrap the mid. sealing pad (6) over the

insulation for fitting (4) (flare nut part).

CAUTION

Be sure to insulate any field piping all the way to the piping

connection inside the unit. Any exposed piping may cause

condensation or burns if touched.

Vinyl tube

Level

Torque wrench

Spanner

Ester oil or ether oil

Piping union

Flare nut

Fig. 6

Fig. 7

Pipe size

(in.)

Tightening torque

(ft.lbf)

Flare dimensions A

(in.)

Flare shape (in.)

φ

1/4

10.4–12.7

0.342–0.358

φ

3/8

24.1–29.4

0.504–0.520

φ

1/2

36.5–44.5

0.638–0.654

φ

5/8

45.6–55.6

0.760–0.776

R0.016-0.031

A

90˚± 2˚

45˚±2˚

Gas pipe

Piping insulation

material (main unit)

Attach to base

Flare nut connection

Turn seams up

Mid. sealing pad (6) (accessory)

Insulation for fitting (4) (accessory)

Gas Piping Insulation Procedure

Liquid Piping Insulation Procedure

(accessory)

Clamp (9)

Piping insulation material

(Field supply)

Clamp (9) (accessory)

Flare nut connection

Turn seams up

Piping insulation material

(Field supply)

Piping insulation material

(main unit)

Attach to base

Main unit

Fig. 8

Liquid pipe

Insulation for fitting (3) (accessory)

Wrap over the top of

the flare nut connection.

Main unit