142

FTX-N/U, FVXS-N, FDMQ-R Series EDUS091558E

3P243521-7L

15

Notes)

Field settings are normally applied to the entire remote control group, however if individual

1.

indoor units in the remote control group require speci

c settings or for con

rmation that

settings have been established, utilize the mode number in parenthesis.

Any features not supported by the connected indoor unit will not be displayed.

2.

When mode 10-2-01 is selected, only the return air temperature value is reported to the

3.

multizone controller.

The actual default deadband value will depend upon the indoor unit model.

4.

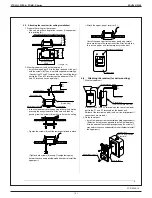

Test Operation

7.

Also see installation manuals furnished with the indoor unit and the

outdoor unit.

Verify that the wiring of the indoor unit and the outdoor unit is completed.

●

Ensure that covers have been replaced on electrical component boxes for both indoor and outdoor

●

units prior to restoring power.

After refrigerant piping, drain piping and electric wiring are completed, clean inside of the indoor unit

●

and decorative panel.

Perform the test operation according to following procedure.

●

To protect the compressor, apply power to the outdoor unit at least 6 hours prior to test operation.

●

Set the remote controller display mode to standard or detailed display mode. Refer to Operation

●

Manual for the setting method.

●

The backlight will be ON for 30 seconds by pressing any button.

The initial push of the button will only turn on the backlight. While the backlight is turned on,

●

the buttons assigned functionality will be available.

Notes for backlight

7-1

Set the operation mode to cooling by

using the remote controller.

Press and hold

7-2

Cancel

button for

4 seconds or longer. Service settings

menu is displayed.

Select

7-3

Test Operation

in the service

settings menu, and press

Menu/OK

button. Basic screen returns and

message “Test Operation” is displayed

at the bottom.

<Basic screen>

1

7-

2

7-

Cool

Return Clean the filter

Set to

68

F

Press and hold

Cancel

button for 4 seconds or

longer while the backlight

is on.

<Service settings menu screen>

3

7-

Setting

1/3

Service Settings

Test Operation

Maintenance Contact

Field Settings

Energy Saving Options

Prohibit Function

Min Setpoints Differential

Press

Menu/OK

button.

01_EN_3P243521-7L.indd 15

11/27/2014 11:21:45 AM

Summary of Contents for FTX-N/U

Page 1: ...Heat Pump Split Type Air Conditioners FTX N U FVXS N FDMQ R Series EDUS091558E...

Page 2: ......

Page 17: ...FTX N U FVXS N FDMQ R Series EDUS091558E 15 C 3D123383 FTX24UVJU C 3D123379 FTX18UVJU...

Page 19: ...FTX N U FVXS N FDMQ R Series EDUS091558E 17 3D112919B FDMQ18 24RVJU 3D112918B FDMQ12RVJU...

Page 20: ...18 FTX N U FVXS N FDMQ R Series EDUS091558E 3D049611A BRC082A43 C 3D091305A BRC1E73...

Page 22: ...20 FTX N U FVXS N FDMQ R Series EDUS091558E 3D107983A RXL24UMVJUA 3D123362 RXL18UMVJUA...

Page 25: ...FTX N U FVXS N FDMQ R Series EDUS091558E 23 3D112629A FDMQ12 18 24RVJU...

Page 32: ...30 FTX N U FVXS N FDMQ R Series EDUS091558E 3D107985A RXL24UMVJUA...

Page 59: ...FTX N U FVXS N FDMQ R Series EDUS091558E 57 3D113126 FDMQ18RVJU...

Page 60: ...58 FTX N U FVXS N FDMQ R Series EDUS091558E 3D113128 FDMQ24RVJU...

Page 62: ...60 FTX N U FVXS N FDMQ R Series EDUS091558E 3D113129 FDMQ24RVJU...

Page 65: ...FTX N U FVXS N FDMQ R Series EDUS091558E 63 3D123455 FTX18UVJU 3D100354 FTX15NMVJU...

Page 66: ...64 FTX N U FVXS N FDMQ R Series EDUS091558E 3D094737 FVXS09NVJU 3D074866A FTX24UVJU...

Page 67: ...FTX N U FVXS N FDMQ R Series EDUS091558E 65 3D094777A FVXS15NVJU 3D094766 FVXS12NVJU...

Page 70: ...68 FTX N U FVXS N FDMQ R Series EDUS091558E 3D123453 RXL18UMVJUA 3D100636 RXL15QMVJUA...

Page 71: ...FTX N U FVXS N FDMQ R Series EDUS091558E 69 3D123454 RXL24UMVJUA...

Page 394: ...392 FTX N U FVXS N FDMQ R Series EDUS091558E 1P124687 1A...

Page 395: ...FTX N U FVXS N FDMQ R Series EDUS091558E 393 1P124687 1A...

Page 396: ...394 FTX N U FVXS N FDMQ R Series EDUS091558E 1P124687 1A...

Page 397: ...FTX N U FVXS N FDMQ R Series EDUS091558E 395 1P124687 1A...

Page 401: ...FTX N U FVXS N FDMQ R Series EDUS091558E 399 3P124623 1E 4 Fig 6 Fig 5 Fig 8 Fig 7...

Page 412: ...410 FTX N U FVXS N FDMQ R Series EDUS091558E 3P124623 1E 15...

Page 422: ...420 FTX N U FVXS N FDMQ R Series EDUS091558E 3P124623 1E 25 Fig 9 Fig 12 Fig 10 Fig 11...

Page 423: ...FTX N U FVXS N FDMQ R Series EDUS091558E 421 3P124623 1E 26 Fig 14 Fig 13 Fig 16 Fig 15...

Page 425: ...FTX N U FVXS N FDMQ R Series EDUS091558E 423 1P126474 1B...

Page 426: ...424 FTX N U FVXS N FDMQ R Series EDUS091558E 1P126474 1B...

Page 427: ...FTX N U FVXS N FDMQ R Series EDUS091558E 425 1P126474 1B...

Page 428: ...426 FTX N U FVXS N FDMQ R Series EDUS091558E 1P126474 1B...

Page 433: ...FTX N U FVXS N FDMQ R Series EDUS091558E 431 3P162015 1A...

Page 434: ...432 FTX N U FVXS N FDMQ R Series EDUS091558E 3P162015 1A...

Page 435: ...FTX N U FVXS N FDMQ R Series EDUS091558E 433 3P162015 1A...

Page 436: ...434 FTX N U FVXS N FDMQ R Series EDUS091558E 3P162015 1A...

Page 455: ...FTX N U FVXS N FDMQ R Series EDUS091558E 453 3P400464 1...

Page 457: ...FTX N U FVXS N FDMQ R Series EDUS091558E 455 3P561172 1...

Page 459: ...FTX N U FVXS N FDMQ R Series EDUS091558E 457 3P534932 1B...

Page 469: ...FTX N U FVXS N FDMQ R Series EDUS091558E 467 3P436077 1...

Page 471: ...FTX N U FVXS N FDMQ R Series EDUS091558E 469 3P436078 1...

Page 472: ...470 FTX N U FVXS N FDMQ R Series EDUS091558E 3P436079 1 14 26 KPS067A44 Snow Hood Outlet...

Page 473: ...FTX N U FVXS N FDMQ R Series EDUS091558E 471 3P436079 1...

Page 475: ...FTX N U FVXS N FDMQ R Series EDUS091558E 473 3P436071 1...

Page 477: ...FTX N U FVXS N FDMQ R Series EDUS091558E 475 3P436072 1...

Page 478: ...476 FTX N U FVXS N FDMQ R Series EDUS091558E 3P436073 1 14 29 KPS063A47 Snow Hood Outlet...

Page 479: ...FTX N U FVXS N FDMQ R Series EDUS091558E 477 3P436073 1...

Page 480: ...478 FTX N U FVXS N FDMQ R Series EDUS091558E...

Page 481: ......

Page 482: ......

Page 483: ......