D-EIMHP01505-22_00EN 44/59

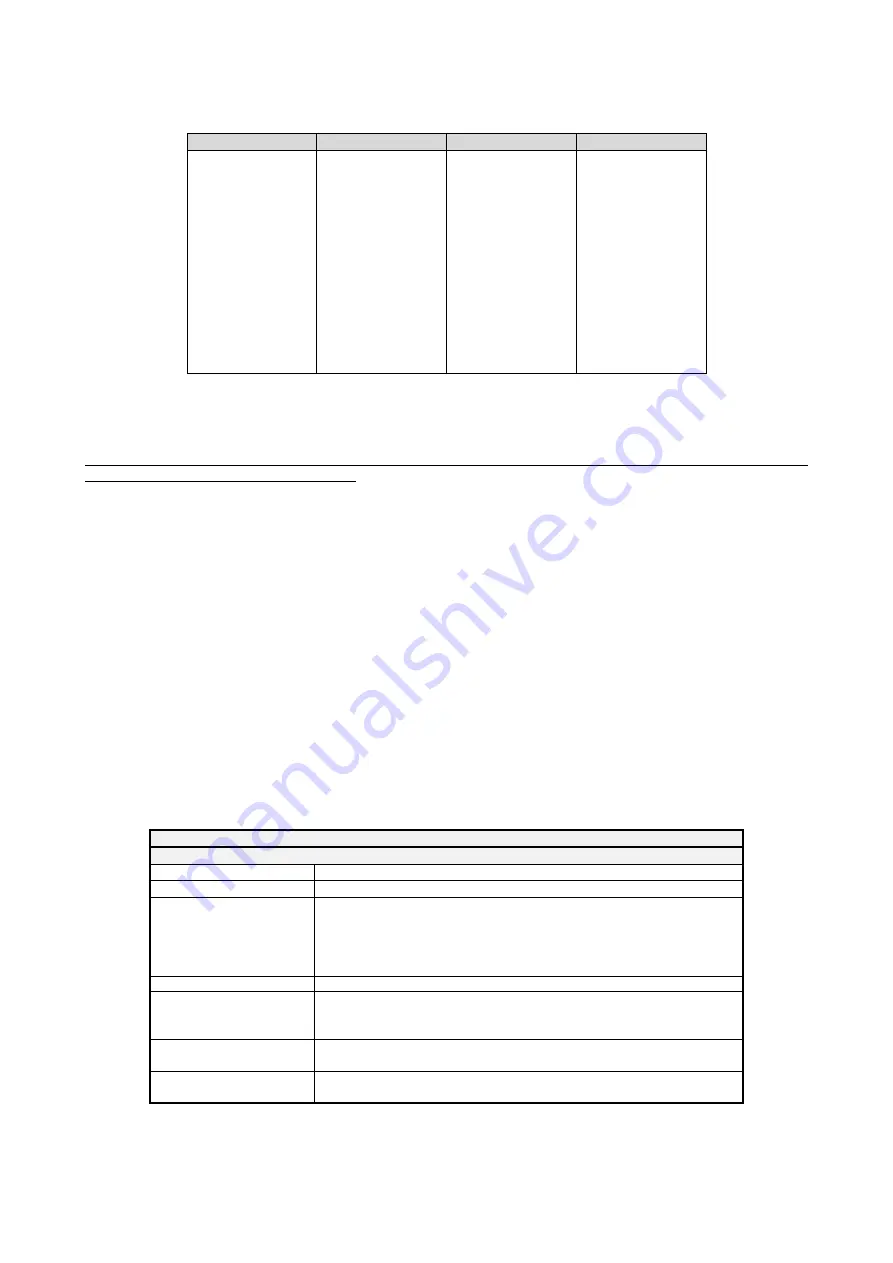

8.1. Pressure / temperature table

°C

Bar

°C

Bar

°C

Bar

°C

Bar

28

2.97

2

7.62

24

16.45

50

31.41

26

3.22

0

8.13

26

17.35

52

32.89

24

3.48

2

8.67

28

18.30

54

34.42

22

3.76

4

9.23

30

19.28

56

36.00

20

4.06

6

9.81

32

20.29

58

37.64

18

4.37

8

10.43

34

21.35

60

39.33

16

4.71

10

11.07

36

22.45

62

41.09

14

5.06

12

11.74

38

23.60

64

42.91

12

5.43

14

12.45

40

24.78

66

44.79

10

5.83

16

13.18

42

26.01

68

46.75

8

6.24

18

13.95

44

27.29

70

48.77

6

6.68

20

14.75

46

28.61

72

50.87

4

7.14

22

15.58

48

29.99

74

53.05

Table 18

– R32 Pressure/Temperature

8.2. Routine maintenance

This unit must be maintained by qualified technicians. Before beginning any work on the system, the personnel shall assure

that all security precautions have been taken.

Neglecting unit maintenance could degrade all parts of the units (coils, compressors, frames, pipes, etc.) with negative

effect on performances and functionality.

There are two different levels of maintenance, which can be chosen according to the type of application (critical/noncritical)

or to the installation environment (highly aggressive).

Examples of critical applications are process cooling, data centres, etc.

Highly Aggressive Environments can be defined as follows:

•

Industrial environment (with possible concentration of fumes result of combustion and chemical process).

•

Coastal environment.

•

Highly polluted urban environment.

•

Rural environment close to of animal excrement and fertilizers, and high concentration of exhaust gas from diesel

generators.

•

Desert areas with risk of sandstorms.

•

Combinations of the above.

Unit exposed to a highly aggressive environment can face corrosion in a shorter time than the ones installed on a standard

environment. Corrosion causes a rapid rusting of the frame core, consequently, decreases unit structure lifetime. To avoid

that, it is necessary to wash periodically the frame surfaces with water and suitable detergents.

In case of part of unit frame paint came off, it is important to stop its progressive deterioration by repainting the exposed

parts using proper products. Please contact factory to get the required products specifications.

In case of just salt deposits are present, it is enough to rinse the parts with fresh water.

Checklist for yearly maintenance of the indoor unit

Indoor Unit: Yearly maintenance plan

Element

Description

Water pressure

Water filter

Water pressure relief

valve

Turn the red knob on the valve counterclockwise and check if it

operates correctly: If you do not hear a clacking sound, contact your

local dealer. In case the water keeps running out of the unit, close both

the water inlet and outlet shut-off valves first and then contact your local

dealer.

Water pressure

Keep water pressure above 1 bar. If lower, add water.

Water filter

Clean the water filter.

NOTICE:

handle the water filter with care.

DO

NOT

use excessive force when you reinsert the water filter so as

NOT

to damage the water filter mesh.

Pressure relief valve

hose

Check the condition and routing of the hose. Water must drain

appropriately from the hose.

Switch box

Carry out a thorough visual inspection of the switch box and look for

obvious defects such as loose connections or defective wiring.

Table 19

– Yearly maintenance checklist for the indoor unit