General Outline

ESIE10-01

1–92

3

11

4

5

1.34

Electrical Installation

General

specifications

Caution:

Q

All electrical connections to the machine must be carried out in compliance with laws and

regulations in force. All installation, operating and maintenance activities must be carried out by

qualified personnel. Please refer to the specific wiring diagram for the machine that you have

purchased and which was sent with the unit. Should the wiring diagram not appear on the machine

or should it have been lost, please contact your dealer who will provide for a copy to be forwarded.

Q

Use copper conductors only. Failure to use copper conductors could cause overheating or

corrosion at the connection points and damage the unit. To avoid interference, all control wires

must be installed separately from the power wires. Use separate electrical conduits for this

purpose.

Q

Before servicing the machine in any way, open the general disconnecting switch on the machine's

main power supply. When the machine is off but the disconnector switch is in the closed position,

unused circuits are live as well. Never open the terminal board box of the compressors before

having opened the unit's general disconnecting switch.

Q

Series units are fitted with high power non-linear electrical components (VPD compressor supply).

These cause superior harmonics and can cause significant leakage towards ground (about 2 A).

The protection for the power supply system must be designed in accordance with the

above-mentioned values.

Q

The short circuit current that can be withstood by the electrical board in accordance with

EN 60439-1, is 25 kA. Please therefore check the short-circuit current at the machine power supply

line connection terminals to ensure that it is less than or equal to the machine panel hold current.

Q

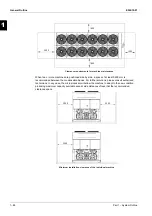

In installations with power supply lines longer than 50 metres, inductive coupling between phases

and between phase and earth generates significant phenomena, namely:

•

Unbalancing of phase currents

•

Excessive voltage drop

In order to limit these phenomena, it is good practise to lay out the phase wires symmetrically, as

described in the figure.

Electrical

components

All power and interface electrical connections are specified in the wiring diagram that is shipped with

the machine. The installer must supply the following components:

Q

Power supply wires (dedicated conduit).

Q

Interconnection and interface wires (dedicated conduit).

Q

Thermal-magnetic circuit breaker of suitable size (please see electrical data).

Electrical wiring

Power circuit:

Connect the electrical power supply cables to the terminals of the general circuit breaker on the

machine's terminal board. The access panel must have a hole of appropriate diameter for the cable

used and its cable gland. A flexible conduit can also be used, containing the three power phases plus

earth. In any case, absolute protection against water penetrating through the connection point must

be ensured.

NO

OK

Installation of long power supply wires

Summary of Contents for EWAD620-C17C-SL

Page 2: ......

Page 8: ...ESIE10 01 1 2 Part 1 System Outline 3 1 1 5 ...

Page 111: ...ESIE10 01 General Outline Part 1 System Outline 1 105 3 1 4 5 1 36 1 Power Compressor 1 2 ...

Page 112: ...General Outline ESIE10 01 1 106 Part 1 System Outline 3 1 1 4 5 1 36 2 Power Compressor 3 ...

Page 113: ...ESIE10 01 General Outline Part 1 System Outline 1 107 3 1 4 5 1 36 3 Kit Pumps ...

Page 122: ...General Outline ESIE10 01 1 116 Part 1 System Outline 3 1 1 4 5 1 36 12 Digital Inputs Board ...

Page 123: ...ESIE10 01 General Outline Part 1 System Outline 1 117 3 1 4 5 1 36 13 Digital Outputs Board ...

Page 124: ...General Outline ESIE10 01 1 118 Part 1 System Outline 3 1 1 4 5 1 36 14 Digital Outputs Board ...

Page 131: ...ESIE10 01 General Outline Part 1 System Outline 1 125 3 1 4 5 1 36 21 EEXV Compressor 1 ...

Page 134: ...General Outline ESIE10 01 1 128 Part 1 System Outline 3 1 1 4 5 1 36 24 EEXV Compressor 2 ...

Page 137: ...ESIE10 01 General Outline Part 1 System Outline 1 131 3 1 4 5 1 36 27 EEXV Compressor 3 ...

Page 138: ...General Outline ESIE10 01 1 132 Part 1 System Outline 3 1 1 4 5 1 36 28 Pumps Control ...

Page 139: ...ESIE10 01 General Outline Part 1 System Outline 1 133 3 1 4 5 1 36 29 Terminals M1 M2 ...

Page 140: ...General Outline ESIE10 01 1 134 Part 1 System Outline 3 1 1 4 5 1 36 30 Terminals M3 ...

Page 141: ...ESIE10 01 General Outline Part 1 System Outline 1 135 3 1 4 5 1 36 31 Terminals M5 MQ ...

Page 148: ...General Outline ESIE10 01 1 142 Part 1 System Outline 3 1 1 4 5 ...

Page 150: ...ESIE10 01 2 2 Part 2 Functional Description 3 1 2 5 ...

Page 170: ...The Digital Controller ESIE10 01 2 22 Part 2 Functional Description 3 1 2 4 5 ...

Page 200: ...Functional Control ESIE10 01 2 52 Part 2 Functional Description 3 1 2 4 5 ...

Page 202: ...ESIE10 01 3 2 Part 3 Troubleshooting 3 1 3 5 ...

Page 254: ...Alarms and Events ESIE10 01 3 54 Part 3 Troubleshooting 3 1 3 4 5 ...

Page 266: ...Controller Inputs and Outputs ESIE10 01 3 66 Part 3 Troubleshooting 3 1 3 4 5 ...

Page 280: ...ESIE10 01 4 2 Part 4 Commissioning and Test Run 3 1 4 5 ...

Page 286: ...Pre Test Run Checks ESIE10 01 4 8 Part 4 Commissioning and Test Run 3 1 4 5 ...

Page 289: ...ESIE10 01 Running Data Part 4 Commissioning and Test Run 4 11 3 4 5 1 ...

Page 290: ...Running Data ESIE10 01 4 12 Part 4 Commissioning and Test Run 3 1 4 5 ...