MAINTENANCE

20

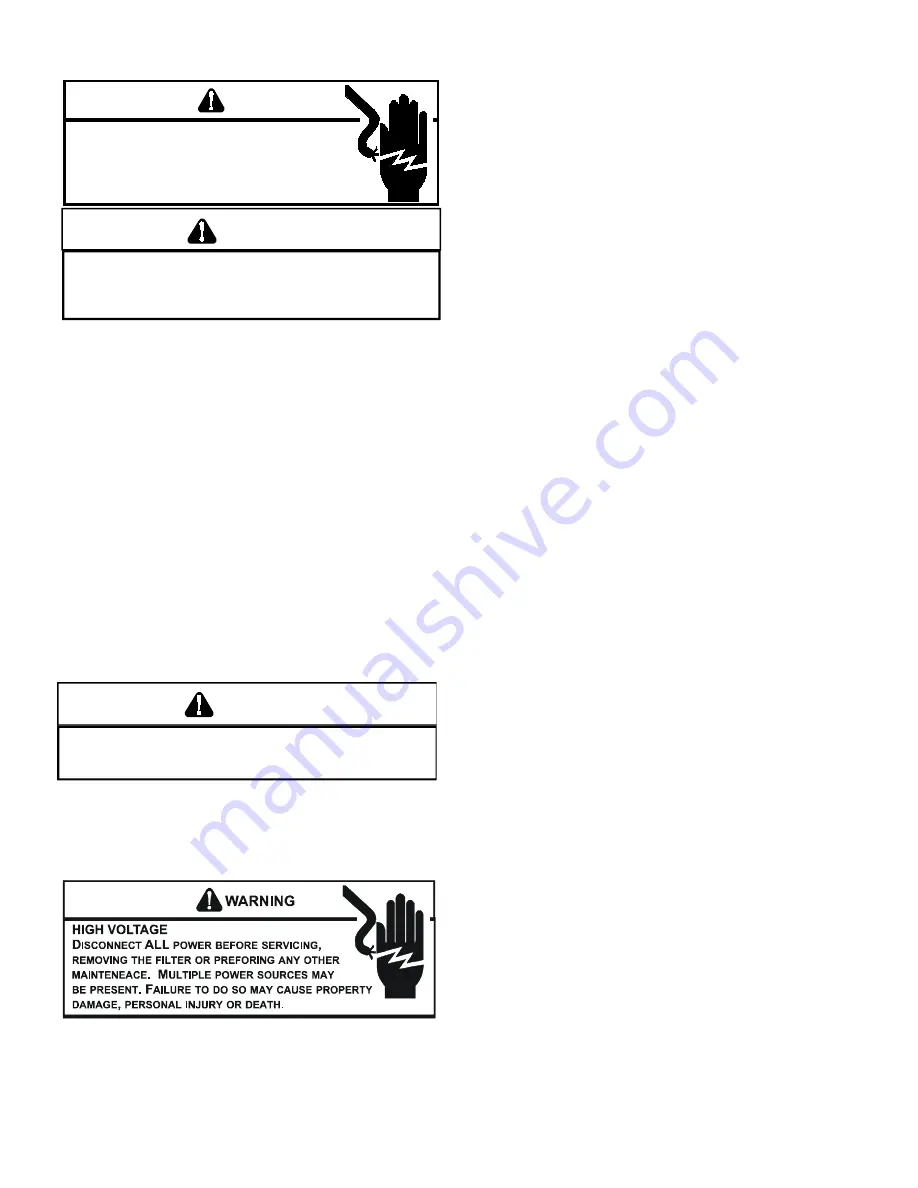

WARNING

HIGH

VOLTAGE

D

ISCONNECT

ALL

POWER BEFORE SERVICING OR

INSTALLING THIS UNIT.

M

ULTIPLE POWER SOURCES MAY

BE PRESENT.

F

AILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

I

F YOU MUST HANDLE THE ITNITOR, HANDLE WITH CARE.

T

OUCHING

THE IGNITOR BODY WITH BARE FINGERS, ROUGH HANDLING, OR

VIBRATION COULD RESULT IN EARLY IGNITOR FAILURE.

O

NLY A

QUALIFIED SERVICER SHOULD EVER HANDLE THE IGNITOR.

CAUTION

ANNUAL INSPECTION

The furnace should be inspected by a qualified installer, or

service agency at least once per year. This check should be

performed at the beginning of the heating season. This will

ensure that all furnace components are in proper working

order and that the heating system functions appropriately.

Pay particular attention to the following items. Repair or

service as necessary.

•

• Flue pipe system. Check for blockage and/or leakage.

Check the outside termination and the connections at

and internal to the furnace.

•

• Heat exchanger. Check for corrosion and/or buildup

within the heat exchanger passageways.

•

• Burners. Check for proper ignition and flame sense.

•

• Wiring. Verify that electrical connections are tight and

free from corrossion.

•

• Filters.

AIR FILTER

N

EVER OPERATE FURNACE WIHTOUT A FILTER INSTALLED AS DUST

AND LINT WILL BUILD UP ON INTERNAL PARTS RESULTING IN LOSS OF

EFFICIENCY, EQUIPMENT DAMAMGE, AND POSSIBLE FIRE.

WARNING

Filters must be used with this furnace. Filters do not ship

with these furnaces but must be provided by the installer for

proper furnace operation.

Dirty filters are the most common cause of inadequate

heating or cooling performance.

Maintenance

Improper filter maintenance is the most common cause of

inadequate heating or cooling performance. Filters should

be cleaned (permanent) or replaced (disposable) every two

months or as required.

Horizontal Unit Filter Removal

Filters in horizontal installations are located in the central

return register.

INDUCED DRAFT AND CIRCULATION BLOWERS

The bearings in the induced draft blower and circulator blower

motors are permanently lubricated by the manufacturer. No

further lubrication is required. Check motor windings for

accumulation of dust which may cause overheating. Clean

as necessary.

FLAME SENSOR (QUALIFIED SERVICER ONLY)

Under some conditions, the fuel or air supply can create a

nearly invisible coating on the flame sensor. This coating acts

as an insulator, causing a drop in the flame sensing signal.

If this occurs, a qualified servicer must carefully clean the

flame sensor with steel wool. After cleaning, the flame sensor

output should be as listed on the specification sheet.

The following is a must for every service technician and

service shop.

1. Dial type thermometers or thermocouple meter (op

-

tional) - to measure dry bulb temperature.

2. Volt-Ohm Meter - to measure amperage and voltage

and to test continuity, capacitors and motor windings.

3. Manometer - to measure static pressure, pressure

drop across coils, filters and draft and to test gas inlet

and manifold pressure.

Other recording type instruments can be essential in solving

abnormal problems, however, in many instances they may

be rented from local sources.

Proper equipment promotes faster, more efficient service and

accurate repairs resulting in fewer call backs.

HEATING PERFORMANCE TEST

Before attempting to diagnose an operating fault, run a

heating performance test and apply the results to the

Service

Problem Analysis Guide.

To conduct a heating performance test, the BTU input to the

furnace must be calculated.

After the heating cycle has been in operation for at least

fifteen minutes and with all other gas appliances turned off,

the gas meter should be clocked.

To find the BTU input, multiply the number of cubic feet of

gas consumed per hour by the heating value of the gas being

used. (The calorific value of the gas being used is found by

contacting your local utility.)

EXAMPLE:

It is found by the gas meter, that it takes forty

(40) seconds for the hand on the cubic foot dial to make

one complete revolution, with all appliances off, except

the furnace. Take this information and locate it on the gas

rate chart. Observe the forty (40) seconds, locate and read

across to the one (1) cubic foot dial column. There we find

the number 90, which shows that ninety (90) cubic feet of

gas will be consumed in one (1) hour.

Summary of Contents for DM80SE

Page 15: ...TROUBLESHOOTING 15 DM80SE U...

Page 16: ...TROUBLESHOOTING 16 DM80SE U...