SYSTEM OPERATION

13

blower. The induced draft blower timing sequence

is not adjustable.

The integrated control module on all models provides

selectable fan on/off delay adjustments.

On/Off Fan Delay Selection

To change the fan on or off delay for COOLING, HP

HEATING & GAS HEATING modes, see the following

steps:

1. Press menu button until LED displays the desired on/off

setting (See MAIN MENU section for selectable blower

on/off delay options). Press option button and LED will

display the selected on/off delay time in seconds.

2. The control shall cycle through available on/off delay

times every time the option button is pressed.

3. When the menu button is pressed, the current displayed

on/off delay shall stop flashing. Press the menu

button again to select the option and the control shall

immediately apply that delay setting and return to the

corresponding main menu.

CIRCULATING AIR AND FILTERS

DUCTWORK - AIR FLOW

Duct systems and register sizes must be properly designed

for the C.F.M. and external static pressure rating of the

furnace. Ductwork should be designed in accordance with

the recommended methods of "Air Conditioning Contractors

of America" manual D.

A duct system should be installed in accordance with

Standards of the National Board of Fire Underwriters for

the Installation of Air Conditioning, Warm Air Heating and

Ventilating Systems, Pamphlets No. 90A and 90B.

A return air filter is not supplied with the furnace. The installer

or servicer must supply a means of filtering all of the return

air. Filter(s) shall comply with UL900 or CAN/ULC-S111

Standards.

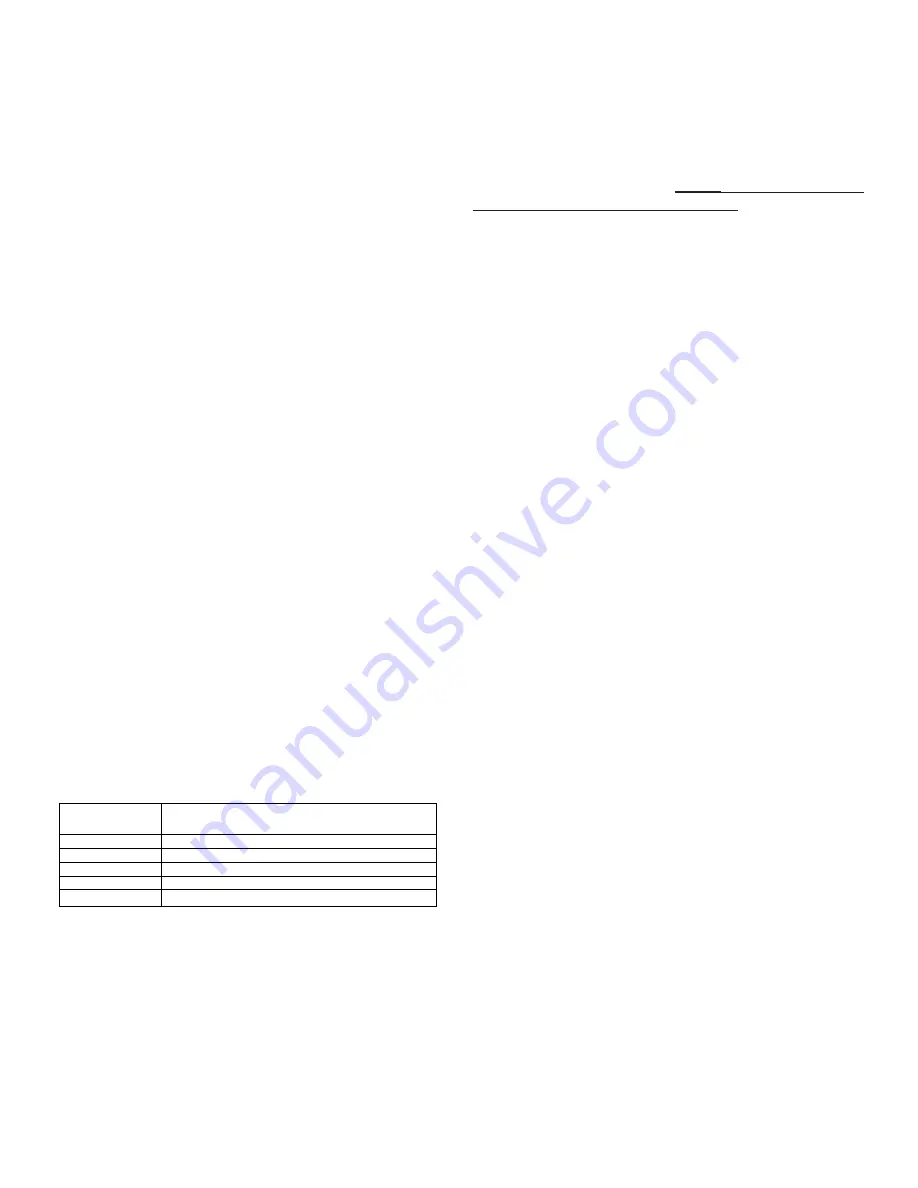

Upflow / Horizontal

Models

Minimum Recommended Filter Size^

*0403A*

1 - 16 X 25 Side or 1 - 14 X 24 Bottom Return

*0603A*

1 - 16 X 25 Side or 1 - 14 X 24 Bottom Return

*0604A*

1 - 16 X 25 Side or 1 - 16 X 25 Bottom Return

*0804A*

1 - 16 X 25 Side or 1 - 16 X 25 Bottom Return

*0805A*

2 - 16 X 25 Side or 1 - 20 X 25 Bottom Return

1

^Large filters may be used, filters may also be centrally located

1

= use 2- 16 X 25 filters and two side returns or 20 X 25 filter on bottom

return if furnace is connected to a cooling unit over 4 tons nominal capacity

Upflow furnaces with air delivery of less than 1800 CFM:

Use one side return or one bottom return ductwork connection.

Upflow furnaces with air delivery of 1800 CFM or higher:

Use two side returns or bottom return or combination of side/

bottom connection.

Guide dimples locate the side and bottom return cutout

locations. Use a straight edge to scribe lines connecting the

dimples. Cut out the opening on these lines. An undersized

opening will cause reduced airflow. For bottom return

connection, remove the bottom of the cabinet before setting

the furnace on the raised platform or return air duct.

A closed return duct system must be used, with the return

duct connected to the furnace.

NOTE:

Ductwork must never

be attached to the back of the furnace.

Supply and return

connections to the furnace may be made with flexible joints

to reduce noise transmission, if desired. If a central return is

used, a connecting duct must be installed between the unit

and the utility room wall so the blower will not interfere with

combustion air or draft. The room, closet, or alcove must not

be used as a return air chamber.

When the furnace is used in connection with a cooling unit,

the furnace should be installed in parallel with or on the

upstream side of the cooling unit to avoid condensation in

the heating element. With a parallel flow arrangement, the

dampers or other means used to control the flow of air must

be adequate to prevent chilled air from entering the furnace

and, if manually operated, must be equipped with means to

prevent operation of either unit unless the damper is in the

full heat or cool position.

When the furnace is heating, the temperature of the return

air entering the furnace must be between

55°F

and

100°F

.

UPRIGHT FILTER INSTALLATIONS

Depending on the installation and/or customer preference,

differing filter arrangements can be applied. Filters can

be installed in the central return register and a side panel

external filter rack kit (upflow filter kit # EFR01). As an

alternative a media air filter or electronic air cleaner can be

used as the requested filter. Refer to the following minimum

filter requirement charts for determination of the minimum

filter area to ensure proper unit performance.

ADDITIONAL FILTERING ACCESSORIES

External Filter Rack Kit (EFR01)

The external filter rack kit is intended to provide a location

external to the furnace casing, for installation of a permanent

filter on upflow model furnaces. The rack is designed to mount

over the indoor blower compartment area of either side panel,

and provide filter retention as well as a location for attaching

return air ductwork.

NORMAL SEQUENCE OF OPERATION

Power Up

•

120 VAC power applied to furnace.

•

Integrated ignition control performs internal checks.

•

LED light will flash once at power up and then remain on.

•

Integrated ignition control monitors safety circuit

continuously.

•

Furnace awaits call from thermostat.

Heating Mode

The normal operational sequence in heating mode is as

follows:

Summary of Contents for DM80SE

Page 15: ...TROUBLESHOOTING 15 DM80SE U...

Page 16: ...TROUBLESHOOTING 16 DM80SE U...