3 About the unit

Installation manual

5

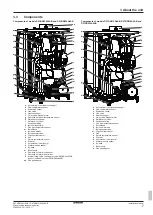

D2CND024A1/4AB + D2TND012~024A4AB

Wall-mounted condensing boiler

3P469346-3N – 2019.11

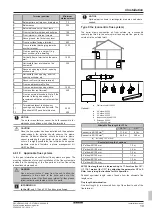

Model

Type

Domestic hot water

supply

Filling loop

D2TND012A4AB

D2TND012

Storage tank

External

D2TND018A4AB

D2TND018

Storage tank

External

D2TND024A4AB

D2TND024

Storage tank

External

A control unit, which contains a user interface, controls the ignition,

safety systems, and other actuators. User interaction is provided via

that user interface, which is composed of an LCD screen and

buttons which is located on the front cover of the unit.

3.1

Safety systems

The unit is equipped with several safety systems, to protect it against

dangerous conditions:

Flue safety system

: This is controlled by the flue gas temperature

sensor located on the flue outlet part of the boiler. It is activated

when the flue gas temperature exceeds safety limits.

Overheating safety system

: This is controlled by the safety limiting

thermostat. It is located on the main heat exchanger and stops the

unit when the flow temperature reaches 100°C, to avoid boiling of

the water, which may damage the unit.

Pump anti-blockage system

: The pump operates for 30 seconds

every 24 hours during long periods of inactivity to ensure it does not

get stuck. To enable this function, the unit must be connected to the

power supply.

Three-way valve anti-blockage system

: In cases where the unit is

non-operational for prolonged periods of time, the three-way valve

switches its position every 24 hours to prevent it from getting stuck.

To enable this function, the unit must be connected to the power

supply.

Safety against dry operation

: This is controlled by the pressure

sensor. It turns off the unit and ensures system safety when the

water pressure of the heating installation falls below 0.6 bar for any

reason.

Flame ionisation control

: This is controlled by the ionisation

electrode. It checks whether a flame forms on the burner surface or

not. If there is no flame, it turns the unit off to stop gas flow and

warns the user.

High pressure protection

:

▪

Pressure sensor

: When heating system pressure reaches

2.8 bar, control unit stops heating operation thus preventing the

pressure from rising.

▪

Safety valve

: When the water pressure of the heating circuit

exceeds 3 bar, some water is automatically drained from the

safety valve to keep the pressure below 3 bar thus protecting the

boiler and heating installation.

Automatic air vents

: There are two air vents; one on the pump,

other on the heat exchanger. They help discharging the air inside the

installation and heating circuit to avoid air traps and consequent

operational problems.

Frost protection safety system

: This function protects the unit and

heating installation from frost damages. It is controlled by the flow

temperature sensor, which is located at the outlet of the main heat

exchanger. This protection activates the boiler pump when the water

temperature drops below 13°C and it activates the burner when the

water temperature drops below 8°C. The unit keeps running until the

temperature reaches 20°C. To enable this function, the unit must be

connected to the power supply and its main gas valve must be open.

Any damage caused by frost is not covered by the warranty.

Low voltage safety system

: This is controlled by the control unit.

When the supply voltage drops below 170 V, the boiler goes to error

mode. It is a blocking error and the boiler will operate without reset

after supply voltage is above 180 V. It is recommended to use a

voltage regulator of suitable power and type in locations with voltage

fluctuations below this limit for faultless operation.

High electric supply current protection system

: A fuse on the

control unit protects equipment and wiring against the damaging

effects of electrical faults which is caused by excess currents, and

disables equipment which is faulty. The fuse "blows" (opens) when

the current carried exceeds the rated value for an excessive time.

Automatic by-pass system

: This ensures that the flow is at all

times continued, to avoid overheating of the heat exchanger. This

system is also supported with a special by-pass function in the

control unit software.

Combustion control safety system

: Boiler control unit monitors the

flame to avoid bad combustion and risky conditions. It also makes

self-inspection against its own malfunctioning and to keep emissions

always at a low level.

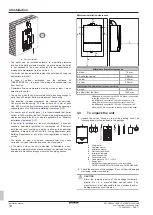

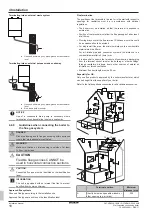

3.2

Dimensions

Top view

200

DN100

127

200

Front view and right side view

255.5

400

590

613.7

Bottom view of model D2CND024A1AB

53

65

61

22.4

161.7

105.8

101.4

71.9

65.1

Summary of Contents for D2CND024A4AB

Page 31: ......