4 Installation

Installation manual

25

D2CND024A1/4AB + D2TND012~024A4AB

Wall-mounted condensing boiler

3P469346-3N – 2019.11

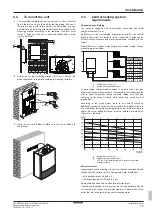

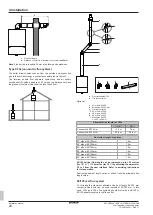

a

1

2

3

4

6

7

5

E

D

F

B

A

a

Use a disconnector or a double check valve according to

local regulations.

After all system connections are performed with care, perform the

following steps:

1

Connect the appliance to the main power supply. Due to low

pressure, error code "Err HJ-09" will appear on the user

interface and the status indicator light will be red.

2

Open

all radiator valves

.

3

Set

all isolating valves

to closed position.

4

Connect fresh water supply pipe to

valve 5

.

5

Open

valves 1, 2, 3, 4, 5, 6

.

6

Slowly turn the

valve 7

to open position until pressure reaches

a value around 0.8 bar for system heights up to 6 metres. For

longer system heights, see

11] to determine filling pressure. Filling

operation should be done slowly. When pressure exceeds

0.8 bar, error code will disappear and the status indicator light

will turn to blue. Turn the

valve 7

off.

7

Turn the

valve

5 off. Remove the filling loop if it is required by

local regulations.

8

Check the central heating circuit - especially the couplings of

the circuit - for leakage.

9

Make sure the automatic air vent valves located on the pump

and heat exchanger are opened. Vent the air from the

installation with the manual air vent screws on the radiators.

Make sure screws are tightened after venting.

10

If after the venting the pressure decreases below 0.8 bar, refill

with water until the pressure reaches 0.8 bar again.

11

Isolate the appliance from power mains.

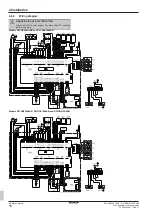

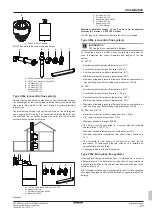

Method 2

(For model D2CND024A4AB)

E

1

2

4

3

6

5

D

F

B

7

a

8

A

a

Use a disconnector or a double check valve according to

local regulations.

After all system connections are performed with care, perform the

following steps:

1

Connect the appliance to the main power supply. Due to low

pressure, error code "Err HJ-09" will appear on the user

interface and the status indicator light will be red.

2

Open all

radiator valves

.

3

Set all

isolating valves

to closed position.

4

Connect the filling loop to the

valve 7 and valve 8

.

5

Set

valves 1, 3, 5, 6 and 8

to open position.

6

Slowly open the

valve 7

until pressure reaches a value around

0.8 bar for system heights up to 6 metres. For longer system

heights, see

"4.5 Central heating system requirements"

11] to

determine filling pressure. Filling operation should be done

slowly. When pressure exceeds 0.8 bar, error code will

disappear and the status indicator light will turn to blue. Turn

the

valve 7

off.

7

You can monitor the system pressure value from the user

interface.

8

Make sure the automatic air vent valves located on the pump

and heat exchanger are opened. Vent the air from the

installation with the manual air vent screws on the radiators.

Make sure screws are tightened after venting.

9

If after the venting the pressure decreases below 0.8 bar, refill

with water until the pressure reaches 0.8 bar again.

10

Set

valve 8

to off position. Remove the filling loop if it is

required by local regulations.

11

Check the central heating circuit - especially the couplings of

the circuit - for leakage.

12

Isolate the boiler from power mains.

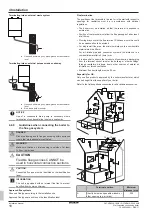

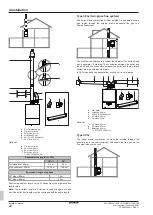

Method 3

(For model D2CND024A1AB)

After all system connections are performed with care, perform the

following steps:

1

Connect the unit to the main power supply. Due to low

pressure, error code "Err HJ-09" will appear on the user

interface and the status indicator light will be red.

2

Open all radiator valves.

3

Set all isolating valves to vertical (open) position.

4

Measure system water height (see

11]).

5

Slowly turn the filling valve until pressure reaches a value

around 0.8 bar for system heights up to 6 metre. For longer

system

heights,

see

11] to determine filling pressure. Filling

operation should be done slowly. When pressure exceeds

0.8 bar, error code will disappear and the status indicator light

will turn to blue. Turn off the filling valve.

6

System pressure value can be monitored from the user

interface.

7

Make sure the automatic air vent valves located on the pump

and heat exchanger are opened. Vent the air from the

installation with the manual air vent screws on the radiators.

Make sure screws are tightened after venting.

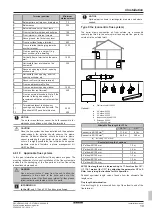

Summary of Contents for D2CND024A4AB

Page 31: ......