5 Commissioning

Installation manual

26

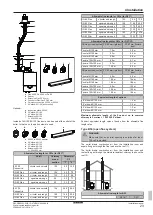

D2CND024A1/4AB + D2TND012~024A4AB

Wall-mounted condensing boiler

3P469346-3N – 2019.11

a

a

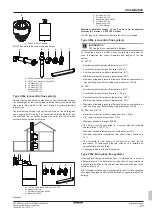

Filling valve

8

If after the venting the pressure decreases below 0.8 bar, refill

the system with water until the pressure reaches 0.8 bar again.

9

Check the central heating circuit - especially the couplings of

the circuit - for leakage.

10

Isolate the unit from power mains.

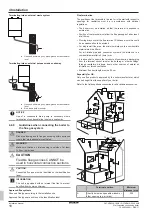

4.10

Converting for use with a different

type of gas

WARNING

Gas conversion operation can only be carried out by

qualified competent persons.

DANGER

Isolate the boiler from the power mains before gas

conversion operation.

INFORMATION

Only for Belgium

Gas conversion from Natural gas to propane gas can only

be executed by Daikin Belux Service Department. Please

contact Daikin Belux Service Department to organise an

appointment on site.

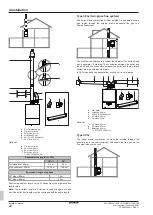

4.10.1

To convert the system for use with a

different type of gas

1

Open the front cover of the unit as described in this manual.

2

To set natural gas, adjust screw on the gas valve to position "1".

3

To set LPG, adjust the screw to position "2".

4

Mount the front cover, connect the unit to the main power

supply.

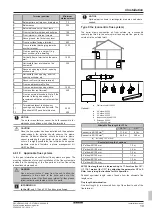

4.10.2

To modify settings for gas conversion

1

Enter the menu section from the user interface. Select service

settings by using the left dial.

2

Press the "Enter" button and choose the password (742) by

using the right dial and press the "Enter" button again.

3

Choose "C" parameters via left dial and press the "Enter"

button.

4

Choose "CE" and press the "Enter" button. It will ask for

password again. Choose the password (115) and press the

"Enter" button.

5

Choose "C0" and press the "Enter" button.

6

To convert to LPG, choose "1" with the right dial and press the

"Enter" button, To convert to Natural gas, choose "0" with the

right dial and press the "Enter" button.

7

Leave the menu screen and go back to the home screen by

using the "Back" button.

INFORMATION

When a conversion is performed, the identification label

shall be marked to show the gas type in use.

5

Commissioning

WARNING

Only qualified persons should conduct commissioning.

CAUTION

Preliminary electrical system checks such as earth

continuity, polarity, resistance to earth and short circuit

must be carried out by using a suitable test meter by a

competent person.

Especially for UK:

It is a requirement that the boiler is installed and commissioned to

the manufacturer’s instructions and the data fields on the

commissioning checklist completed in full.

To instigate the boiler guarantee the boiler needs to be registered

with the manufacturer within one month of the installation.

To maintain the boiler guarantee it is essential that the boiler is

serviced annually by a Gas Safe registered engineer who has been

trained on the boiler installed. The service details should be

recorded on Service Interval Record and left with the householder.

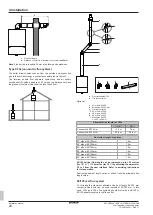

5.1

To fill the condensate trap

INFORMATION

Water must be poured into the

inner

tube.

Fill the condensate trap by pouring 0.2 litres of water from the boiler

flue outlet.

Summary of Contents for D2CND024A4AB

Page 31: ......