IOM 1242-2 • PATHFINDER

®

MODEL AWV CHILLERS

18 www.DaikinApplied.com

I

nsTallaTIon

and

a

pplICaTIon

C

onsIderaTIons

equipment including motor-compressors, and controllers from

the circuit feeder.” Select and locate the disconnect switch per

the NEC

®

guidelines.

Terminals are provided in a unit control panel for optional

field hookup of the control circuit to a separate fused 115-volt

power supply in lieu of the standard factory installed control

transformer.

Use with On-Site Generators

Switching from site grid power to generator power and vice

versa requires that the chiller must either be powered down

or the power must be off for more than five seconds to avoid

sending out of phase voltage to the chiller. A properly installed,

fully synchronized Automatic Transfer Switch must be used to

transfer power if the chiller is running under load.

Generator Sizing

WARNING

Generator must be sized by an electrical engineer familiar

with generator applications.

Transfer Back to Grid Power

Proper transfer from stand-by generator power back to grid

power is essential to avoid chiller damage and must be used to

ensure proper function of the unit.

WARNING

Stop the chiller before transferring supply power from the

generator back to the utility power grid. Transferring power

while the chiller is running can cause severe chiller damage.

The necessary procedure for reconnecting power from the

generator back to the utility grid is as follows:

1.

Set the generator to always run five minutes longer than

the unit start-to-start timer, which can be set from two to

sixty minutes, while keeping the chiller powered by the

generator until the fully synchronized Automatic Transfer

Switch properly hands over chiller power from the site.

2.

Configure the transfer switch provided with the

generator to automatically shut down the chiller before

transfer is made. The automatic shut-off function can

be accomplished through a BAS interface or with the

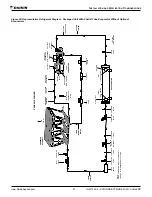

“remote on/off” wiring connection shown in the field

wiring diagrams.

A start signal can be given anytime after the stop signal since

the three-minute start-to-start timer will be in effect.

Long Term Storage

This information applies to new units being stored waiting

for startup or to existing units that may be inoperative for an

extended period of time.

The chiller must be stored in a dry location and protected from

any damage or sources of corrosion. A Daikin Applied service

representative must perform an inspection and leak test of

the unit on a minimum quarterly schedule, to be paid by the

owner or contractor. Daikin Applied will not be responsible for

any refrigerant loss during the storage time or for repairs to the

unit during the period of storage, or while moving the unit from

the original location to a storage facility and back to any new

installation location. If there is concern about the possibilities of

damage and loss of charge during storage, the customer can

have the charge removed and stored in recovery cylinders.

CAUTION

If the temperature of where the chiller is located is expected to

exceed 130°F (54.4°C), then the refrigerant must be removed.

For additional tasks required, contact a Daikin Applied service

representative.

Summary of Contents for AWV008

Page 4: ......