6-15

Chapter 6

W

elding Condition

S

ETTING

W

ELDING

C

ONDITIONS

W

ELDING

C

ONDITION

C

HAPTER

6

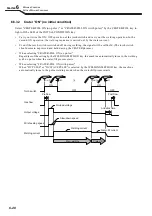

6.6 Setting Welding Conditions

This section explains how to set the welding conditions (welding mode or welding parameters).

6.6.1 Welding mode setting

This section describes how to set welding mode such as selection of shielding gas or wire. Refer to "2.1.2

-

Applicable welding mode" about combination of selectable welding mode.Selecting unavailable

combination displays “- - -“ on the right/left digital meter in a flashing mode.

<Relationship of wire diameter and welding current at aluminum welding (Reference)>

Aluminum material

Wire diameter

(mm

Φ

)

Welding method

Range of stable welding

power source (A)

HARD ALUMINUM

(A5183, A5336 etc.)

1.0

DC

60 to 150

DC PULSE/DC WAVE PULSE (*)

50 to 150

1.2

DC

75 to 250

DC PULSE/DC WAVE PULSE (*)

50 to 250

1.6

DC

100 to 320

DC PULSE/DC WAVE PULSE (*)

75 to 320

SOFT ALUMINUM

(A4043 etc.)

1.2

DC

90 to 250

DC PULSE/DC WAVE PULSE (*)

60 to 300

1.6

DC

100 to 320

DC PULSE/DC WAVE PULSE (*)

75 to 320

*: To use the DC WAVE PULSE, you need OP-WAVE (optional).

Is

IE

I

F

A

m/min.

V

s

A

V

s

㸣

V

sec.

Hz

m/min.

JOB No.

SYN.

INDIV.

SYNERG.

WAVE

(3 sec.)

LOAD

SAVE

ARC

START

ENTER

0.8

1.0

1.2

MAG(20 CO

2

)

MIG(2.5 CO

2

)

MIG(Ar)

DC PULSE

DC

G3Si1

CrNi

WIRE DIA. (mm) key

WIRE MATERIALS key

GAS key

TRAVEL SPEED key

WELDING METHOD key

CONSTANT PENETRATION key