6-7

Chapter 6

W

elding Condition

F

UNCTION

ON

O

PERATION

P

ANEL

W

ELDING

C

ONDITION

C

HAPTER

6

15

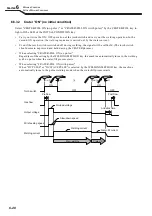

CRATER-FILL key

Select the crater treatment method or arc spot at the end of welding.

The LED of the parameter in selection lights up.

• For details of the crater treatment (

-

• For details of arc spot (

16

SPOT TIME key

Sets the welding time when "ARC SPOT" is selected by the CRATER-FILL key. (

spot time)

Pressing this key makes the LED lit, enabling to adjust the welding time by the parameter

adjustment knob.

The set time is displayed on the left digital meter.

17

ARC CONTROL key

Set the arc characteristics (soft to hard). (

Arc characteristics adjustment)

Pressing this key makes the LED lit, enabling to adjust the arc characteristics by the

parameter adjustment knob. The arc characteristic in adjustment is displayed on the right

digital meter.

18

INITIAL CONDITION key

When "CRATER-FILL ON" is selected by the CRATER-FILL key, the sequence of initial

condition is added before the welding. (

Pressing this key makes the LED lit, adding the sequence of initial condition.

19

CONSTANT PENETRATION key

Activates the penetration control. (

Penetration control adjustment)

Press this key makes the LED lit, and automatically adjusts the wire feed speed so that

the welding current becomes always constant even with the wire feeding length changed.

This function is available only when the "MILD STEEL CORED", "MILD FLUX CORED", "SUS

SOLID" or "SUS FLUX CORED" is selected by the WIRE MATERIALS key.

20

WAVE FRQ key

Sets the wave frequency when "DC WAVE PULSE" is selected by the WELDING METHOD

key. (

Pressing this key lights the LED, enabling to adjust the wave frequency by the parameter

adjustment knob.

The set wave frequency is displayed on the left digital meter.

21

TORCH key

Select air-cooled welding torch or water-cooled welding torch to be used. Switching the

mode is enabled by pressing the key.

• When the LED is ON: water-cooled welding torch mode

• When the LED is OFF: air-cooled welding torch mode

22

VOLT.ADJUST key

Sets welding voltage. Switching the mode is enabled by pressing the key.

• When the LED of the VOLT. ADJUST key is on: SYNERGIC mode. (The welding voltage

is automatically set according to the set welding current. To fine-tune welding voltage,

adjust the synergic fine adjustment knob.)

• When the LED of the VOLT. ADJUST key is off: INDIVIDUAL mode. (In the individual

adjustment setting, welding current and welding voltage are adjusted respectively.)

23

WELD MONITOR key

Sets welding control function. (See Chapter 7 Administrator Functions.)

Pressing this key for a second or more lights up the LED, and the sequence transits to the

welding control mode.

24

LOAD key

Reads the registered welding condition from the internal memory. (

-

Function of Welding Conditions)

25

SAVE key

Registers the set welding condition in the internal memory. (

26

ENTER key

Carries out the administrative functions such as key lock, password, and registration of

welding condition to the memory.

Depressing the key for three seconds or more makes the LED lit, enabling the key lock

function.

27

WARNING/Temperature LED

Lights up or flashes when any failure or abnormal condition occurs in the welding power

source. (

28

USB connector

For variety of registered data, writes to or reads from the USB memory. (

Chapter 7

29

Terminals for service use

Terminals for the OTC service use.

*1: Selective options can be optionally available (OP).

*2: When you select option, item is added.

No.

Name

Function