―13―

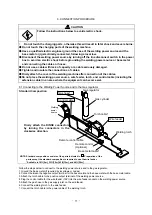

6. CONNECTION PROCEDURE (continued)

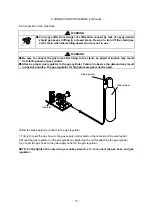

6.4 Connection of the Gas Hose

WARNING

●

You may suffer from danger of suffocation caused by lack of oxygen when

shield gas keeps drifting in a closed place. Be sure to turn off the shield gas

at the main when the welding power source is not in use.

WARNING

●

Be sure to connect the gas hose after fixing to the stand, as physical injuries may result

from falling down of gas cylinder.

●

Attach a proper gas regulator to the gas cylinder. Failure to observe the demand may result

in physical injuries. The gas regulator for high pressure gas must be used.

Follow the steps below to connect to the gas regulator.

1. Firmly connect the gas hose to the gas supply inlet located on the rear side of the wire feeder.

2. Mount the gas regulator on the gas cylinder by tightening the nut for attaching the gas cylinder .

3. Connect the gas hose to the gas supply outlet on the gas regulator.

NOTE: Firmly tighten the nuts using a monkey wrench, etc. to connect the gas hose and gas

regulator.

Gas cylinder

Gas regulator

Gas inlet

-

13

-