―9―

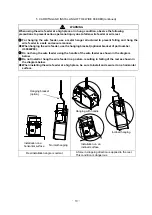

5. CARRYING AND INSTALLING OF THE WIRE FEEDER

5.1 Transportation

WARNING

Observe the following to avoid damage to the wire feeder or physical injury when carrying the

equipment.

●

Do not touch the charging parts inside or outside of the wire feeder.

●

Disconnect the welding power source by turning off the line disconnect switch

in the power box to avoid an electric shock before carrying the equipment.

●

Be sure to detach the wire reel from the fire feeder before lifting the equipment

to the high places by a crane.

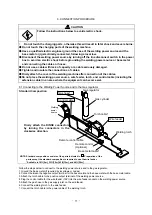

5.2 Installation

WARNING

When installing the wire feeder, follow the instructions below to avoid occurrence of fires

during welding and physical damage by fume gas.

●

Do not place the welding machine near combustible materials and flammable gas.

●

Remove combustible materials to prevent dross coming into contact with

combustible objects. If that not possible, cover them with noncombustible covers.

●

To avoid gas poisoning and danger of suffocation, wear a gas mask or adequately

ventilate when using the welding machine in the place regulated by a local law.

●

To prevent disorder or poisoning caused by fume, wear a gas mask or weld at a

partial exhaust facility approved by the local regulation.

●

Adequately ventilate or wear a gas mask when using the welding machine in a

tank, a boiler, a hold of a ship, because heavier gas such as carbon dioxide or

argon gases are drifting there.

●

When using the welding machine at a narrow space, comply with a trained

supervisor’s directions. And be sure to wear a gas mask.

●

Do not operate the welding machine near the place where degreasing, cleansing,

and spraying are performed. Otherwise, poisonous gas may be generated.

●

Be sure to wear a gas mask or adequately ventilate when welding a coating

steel plate. (Poisonous gas and fume may be generated.)

●

Do not place the welding power source, wire feeder, torch, and control cable

(including the extension cable) in an area where the equipment can become

wet.

INSTALLATION PLACE

Follow the instructions below when selecting an installation place of the wire feeder.

●

Do not install the wire feeder in the indoor place subject to direct sunlight and rain.

●

Install the wire feeder in the place where the ambient temperature is between -10 ˚C and +40 ˚C.

●

Do not place the welding power source, wire feeder, torch, and control cable (including the

extension cable) in an area where the equipment can become wet.

●

Use a wind shield to protect arc from a wind blow when welding on a windy day.

-

9

-