S0702170K

Page 7

Hydraulic System Troubleshooting, Testing and

Adjustment

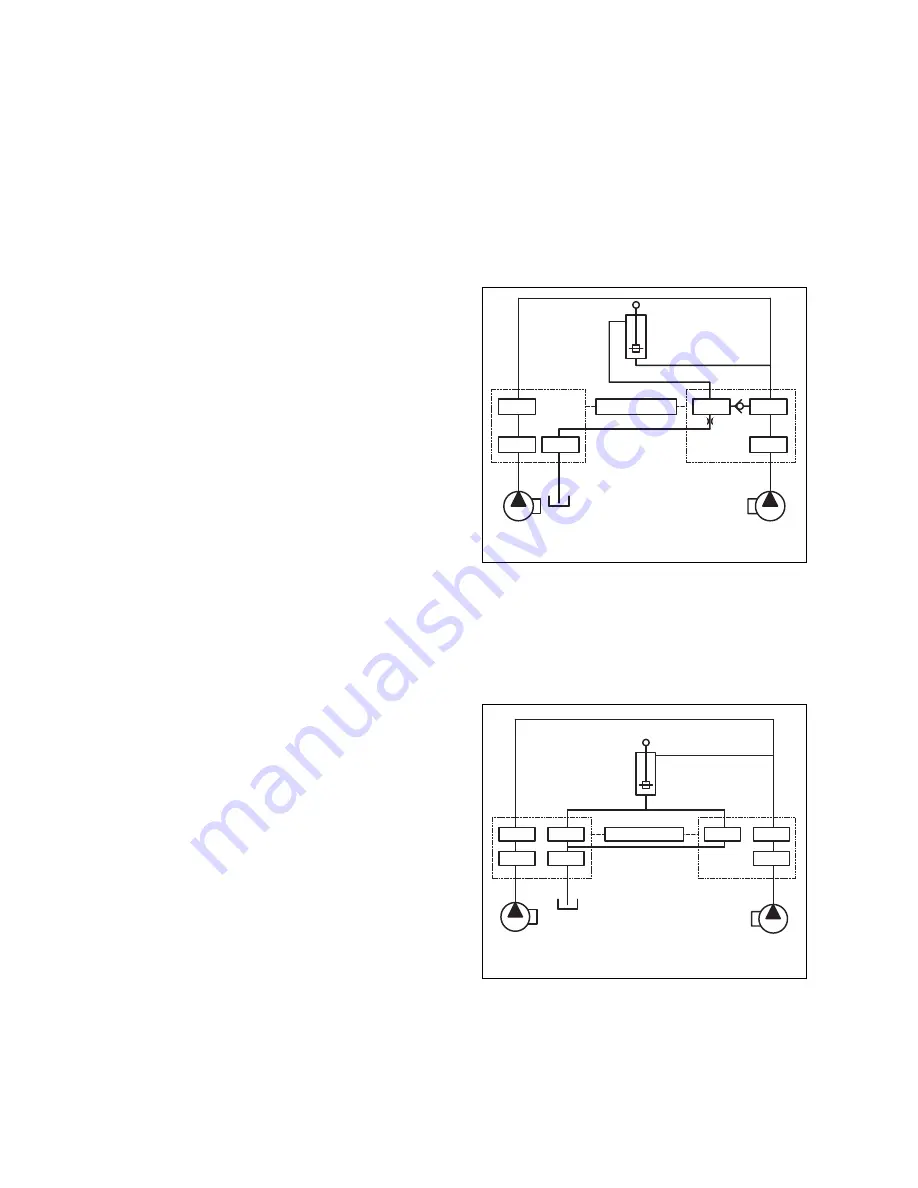

ARM OPERATING CIRCUIT

The arm operating circuit includes both the right and left hydraulic main pumps, the right and left halves of

the control valve, a slow return orifice, and the arm cylinder. The circuit can be operated in the two-stage

speed control mode which works through both halves of the control valve and doubles the volume of oil

flowing to the cylinder.

Overload relief valves set at 360 kg/cm

2

(5,112 psi) have been installed at the

AM 1

and

AMD 1

ports on

the right side of the control valve to protect the circuit and system components from possible damage

caused by shocks and/or overload pressure. Additional protection - to prevent cavitation of the cylinder - is

provided by a make-up valve and reservoir return circuit, which ensures that the volume of oil going to the

cylinder will not exceed the volume of oil coming out.

ARM CROWD CIRCUIT

When the arm control lever is put in the crowd

mode, the left side pilot valve generates

secondary pressure that is transmitted to the

AM1 and AM2 spools of the control valve

simultaneously.

When secondary pilot pressure reaches 7 - 9

kg/cm

2

(100 - 130 psi), the arm control valve

spools AM1 and AM2 open. Output flow from

both halves of the pump assembly is directed to

the arm cylinder.

When working in the arm crowd mode, under

certain conditions, oil in the arm cylinder could

suddenly be forced out by the weight of the arm

and bucket. Insufficient oil flow to the cylinder

could lead to cavitation in the cylinder and/or

surging or irregular movement. This is prevented

by a regeneration valve attached to the control

valve which maintains the balance between oil

flowing into the cylinder and oil flowing out.

ARM DUMP CIRCUIT

When the arm control lever is put in "dump"

mode, the left side pilot valve generates

secondary pilot pressure that goes to both

spools AM1 and AM2 of the control valve

simultaneously.

When pilot pressure reaches 7 - 9 kg/cm

2

(100 -

130 psi), the control spools open, allowing oil

from PUMP (L) and PUMP (R) to flow to the arm

cylinder.

PUMP(L)

PUMP(R)

PL

PR

TL

CONTROL

VALVE(L)

ARM

CYLINDER

CONTROL

VALVE(R)

AMD1

AM1

REGENERATION VALVE

AM2

ARS1580L

PILOT VALVE

Figure 4

PUMP(L)

PUMP(R)

TL

PR

AM2

PL

CONTROL

VALVE(L)

ARM

CYLINDER

CONTROL

VALVE(R)

AMD1

ARS1590L

AMD2

PILOT VALVE

AM1

Figure 5

Summary of Contents for Solar 225LC-V

Page 2: ......

Page 4: ......

Page 7: ...1SAFETY ...

Page 8: ......

Page 46: ...S0102000 Page 38 Track Excavator Safety ...

Page 47: ...1SPECIFICATIONS ...

Page 48: ......

Page 54: ...S0205015K Page 6 Specifications for Solar 225LC V Return to Master Table of Contents ...

Page 70: ...S0205015K Page 22 Specifications for Solar 225LC V Return to Master Table of Contents ...

Page 71: ...1GENERAL MAINTENANCE ...

Page 72: ......

Page 86: ...S0302000 Page 14 General Maintenance Procedures ...

Page 99: ...1UPPER STRUCTURE ...

Page 100: ......

Page 102: ...S0402040K Page 2 Cab TABLE OF CONTENTS Removal 3 Installation 6 ...

Page 116: ...S0403050K Page 8 Counterweight Return to Master Table of Contents ...

Page 140: ...S0407000 Page 6 Swing Bearing ...

Page 165: ...1LOWER STRUCTURE AND CHASSIS ...

Page 166: ......

Page 192: ...S0505030 Page 26 Track Assembly Return to Master Table of Contents ...

Page 193: ...1ENGINE AND DRIVE TRAIN ...

Page 194: ......

Page 205: ...S0605060K Page 11 Air Conditioner Face and Defroster ARS1300L Figure 12 ...

Page 229: ...S0609000 Page 9 Drive Coupling Main Pump Figure 10 DRIVE COUPLING INSTALLATION UCHIDA PUMP ...

Page 234: ...S0609000 Page 14 Drive Coupling Main Pump ...

Page 235: ...1HYDRAULICS ...

Page 236: ......

Page 249: ...S0702170K Page 13 Hydraulic System Troubleshooting Testing and Adjustment ...

Page 272: ...S0702170K Page 36 Hydraulic System Troubleshooting Testing and Adjustment ...

Page 274: ...S0703010K Page 2 Accumulator TABLE OF CONTENTS General Description 3 Specifications 4 ...

Page 297: ...S0705000 Page 9 Cylinders ...

Page 301: ...S0705000 Page 13 Cylinders ...

Page 311: ...S0705000 Page 23 Cylinders ...

Page 315: ...S0705000 Page 27 Cylinders ...

Page 324: ...S0705000 Page 36 Cylinders 17 Force out pin bushing 1 from body of cylinder Figure 28 ...

Page 328: ...S0705000 Page 40 Cylinders ...

Page 335: ...S0707200 Page 7 Swing Motor Return to Master Table of Contents ...

Page 341: ...S0707200 Page 13 Swing Motor Return to Master Table of Contents SPECIAL TOOLS Figure 6 ...

Page 358: ...S0707200 Page 30 Swing Motor Return to Master Table of Contents ...

Page 452: ...S0708320 Page 40 Main Pump With Regulator Return to Master Table of Contents ...

Page 458: ...S0709401K Page 6 Main Control Valve Kayaba Figure 1 ...

Page 459: ...S0709401K Page 7 Main Control Valve Kayaba Figure 2 ...

Page 461: ...S0709401K Page 9 Main Control Valve Kayaba ...

Page 463: ...S0709401K Page 11 Main Control Valve Kayaba Figure 4 ...

Page 475: ...S0709401K Page 23 Main Control Valve Kayaba Figure 16 ...

Page 508: ...S0709401K Page 56 Main Control Valve Kayaba Figure 54 ...

Page 563: ...1ELECTRICAL SYSTEM ...

Page 564: ......

Page 618: ...S0802220K Page 54 Electrical System ...

Page 637: ...S0802220K Page 73 Electrical System ...

Page 649: ...1ATTACHMENTS ...

Page 650: ......

Page 670: ......