- 47 -

TECHNICAL INFORMATION

2.22. Engine Inspection

2.22.1. Stopping engine

After checking the engine for any unusual condition at the idling speed, then turn the key

switch to stop the engine.

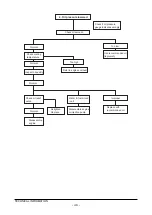

2.22.2. General engine inspection cycle

2.22.3. Use of original parts for repair and replacement

For engine is being mechanically harmonized with many parts, only when the original parts

that the manufacture recommends to use is used, the engine trouble would be preventively

maintained and capable to keep up the maximum performances.

For the analogous parts not the original parts are poor in qualities and gives ill performances,

it may rather bring early engine failure

: Check & adjust : Replace

Inspection

Daily

Every

Every

Every

Every

Every

Remark

50hrs

200hrs 500hrs

600hrs 1200hrs

Check for leakage(hoses, clamp)

Check the water level

Cooling

Change the coolant water

System

Adjust the V-belt tension

Every

2,000hrs

Clean the radiator

Check for leakage

Lubrication

Check the oil level gauge

System

Change the lubricating oil

1st

Replace the oil filter cartridge

1st

Intake &

Check the leakage for

Exhaust

intercooler (hoses, clamp)

System

Clean and change

clean

the air cleaner element

Check the leakage fuel line

Clean the fuel strainer

of fuel feed pump

Remove sediment from

Fuel

fuel tank

System

Drain the water in separator

Replace the fuel filter element

Check fuel injection timing

When

necessary

necessary

Check the injection nozzles

When

necessary

Check the state of exhaust gas

Check the battery charging

Engine

Check the compression

When

Adjust

pressure

necessary

Adjust Intake/Exhaust

1st

When

valve clearance

necessary

Summary of Contents for DE12T

Page 2: ......

Page 187: ... Engine Assembly DE12TIS ECIEA 183 APPENDIX EE6OM026 ...

Page 188: ......