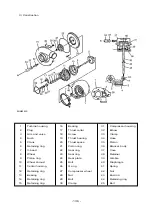

(5) Screw in the bobbin until the edge of

the bobbin contacts the bottom of the

joint.

Note : Before installing the bobbin

in the joint, apply grease to

the O-ring.

- 130 -

EA2M4027

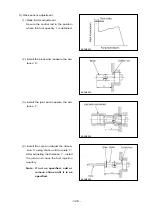

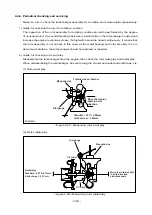

10) Rack sensor adjustment

(1) Secure the control lever in the full

speed position.

(2) Specified output voltage

Read the specified output voltage and

the specified rack position from the

Rack position - Voltage graph in the

calibration data.

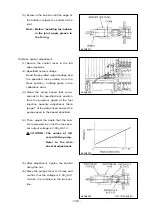

(3) Read the pump speed that corre-

sponds to the specified rack position

from the governor graph of the fuel

injection quantity adjustment table

(page 1 of the data sheet) and set the

pump speed to the speed specified.

EA2M4028

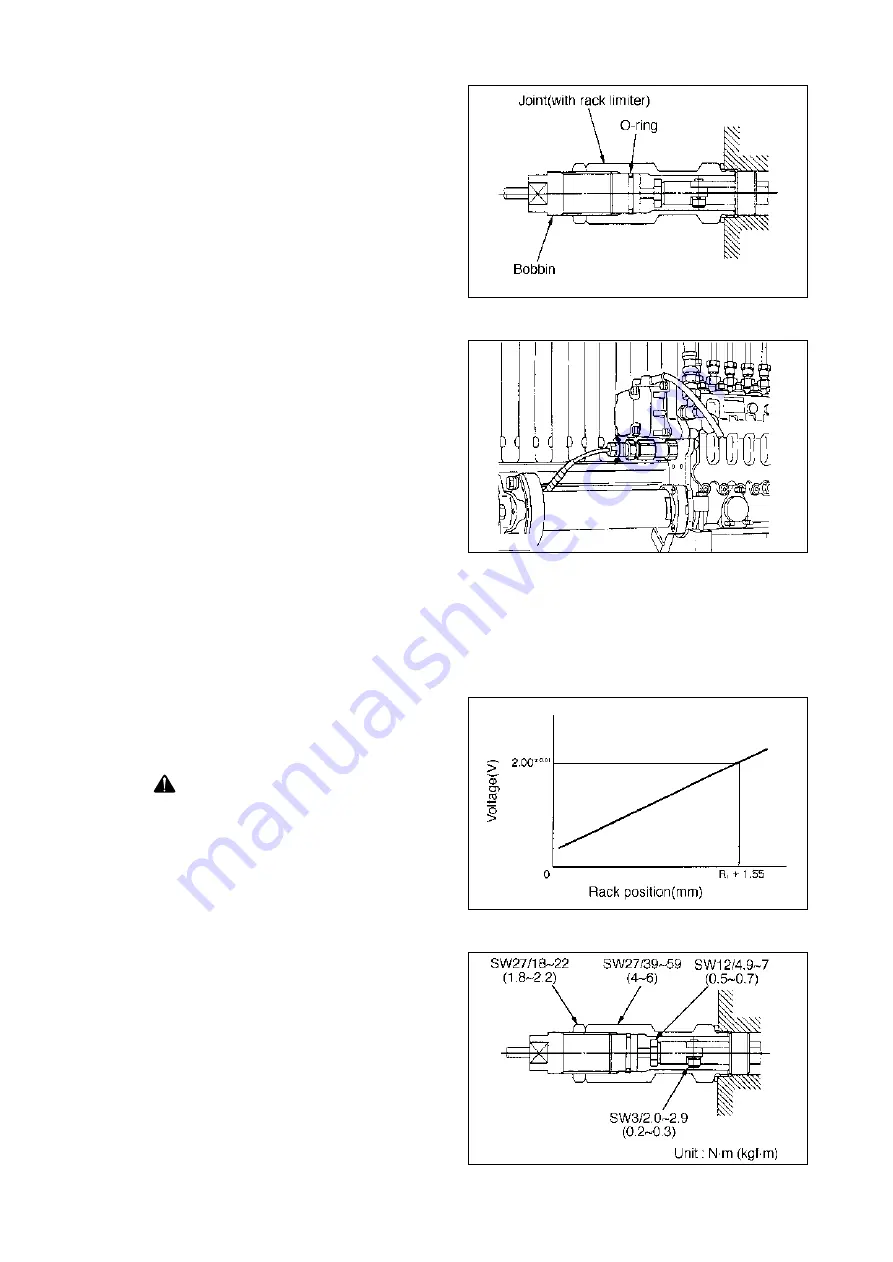

(4) Then, adjust the depth that the bob-

bin is screwed in so that the rack sen-

sor output voltage is 2.00

L

0.01 V.

COUTION : The values at left

vary with the pump.

Refer to the data

sheet at adjustment.

EA2M4029

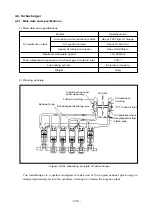

(5) After adjustment, tighten the bobbin

using the nut.

(6) Move the pump’s lever 2~3 times and

confirm that the voltage is 2.00

L

0.01

V when it is returned to the full posi-

tion.

EA2M4030