ERASING ALL REMOTES and THEIR BUTTONS FROM THE OPERATOR

1) Ensure the ba ery is connected to the Operator.

2) Press the SET bu on to enter the Programming Menu (

Pr

).

3) Press the DOWN bu on un l the Remote Menu (

rc

) is visible.

4) Press the SET bu on to enter the Remote Menu. The display will change to

LE

(Learn).

5) Press the DOWN bu on un l

Er

is visible.

6) Press the SET bu on. While holding the SET bu on, press either the UP or DOWN

bu on. Con nue to hold the two bu ons un l the visible countdown on the LED

display is complete (E5 to E0). All remotes have now been erased from the operator.

7) Exit the Programming Menu by scrolling to

bc

and pressing the SET bu on.

R c

SET

p r

SET

b c

SET

L E

E r

PROGRAMMING A REMOTE BUTTON TO SET THE HOLIDAY LOCKOUT FEATURE

1) Ensure the ba ery is connected to the Operator.

2) Press the SET bu on to ac vate the Programming Menu (

Pr

).

3) Press the DOWN bu on un l the Remote Menu (

rc

) is visible.

4) Press the SET bu on to enter the Remote Menu. The display will change to

LE

(Learn).

5) Press the DOWN bu on un l

Lo

is visible.

6) Press and hold the remote bu on that will be used to ac vate the Holiday Lockout

feature.

7) While holding the remote bu on, press the SET bu on on the operator. The display

will indicate the stored posi on of the remote being programmed (01 to 64). The

bu on has now been programmed.

8) To exit the Holiday Lockout Menu (

Lo

)

,

use the UP or DOWN bu ons to scroll to

bc

and press the SET bu on. This will return you to the Programming Menu (

Pr

).

R c

SET

p r

SET

b c

SET

L E

18

L o

SET

1) Ensure the ba ery is connected to the Operator.

2) Press the SET bu on to enter the Programming Menu (

Pr

).

3) Press the DOWN bu on un l the Factory Reset (

Fr

) is visible.

4) Press the SET bu on. While holding the SET bu on, press either the UP or DOWN

bu on. Con nue to hold the two bu ons un l the visible countdown on the LED

display is complete (F9 to F0). Factory Reset is complete.

5) The screen with return to the Programming Menu (

Pr

).

6) Press the DOWN bu on un l

Li

is visible and proceed to reprogram the doors limits.

7) Reprogram all remotes and operator se ngs.

FACTORY RESET ....Menu 8

F r

SET

p r

p r

l i

5

2

1

3

6

4

7

1

4

5

6

1

2

3

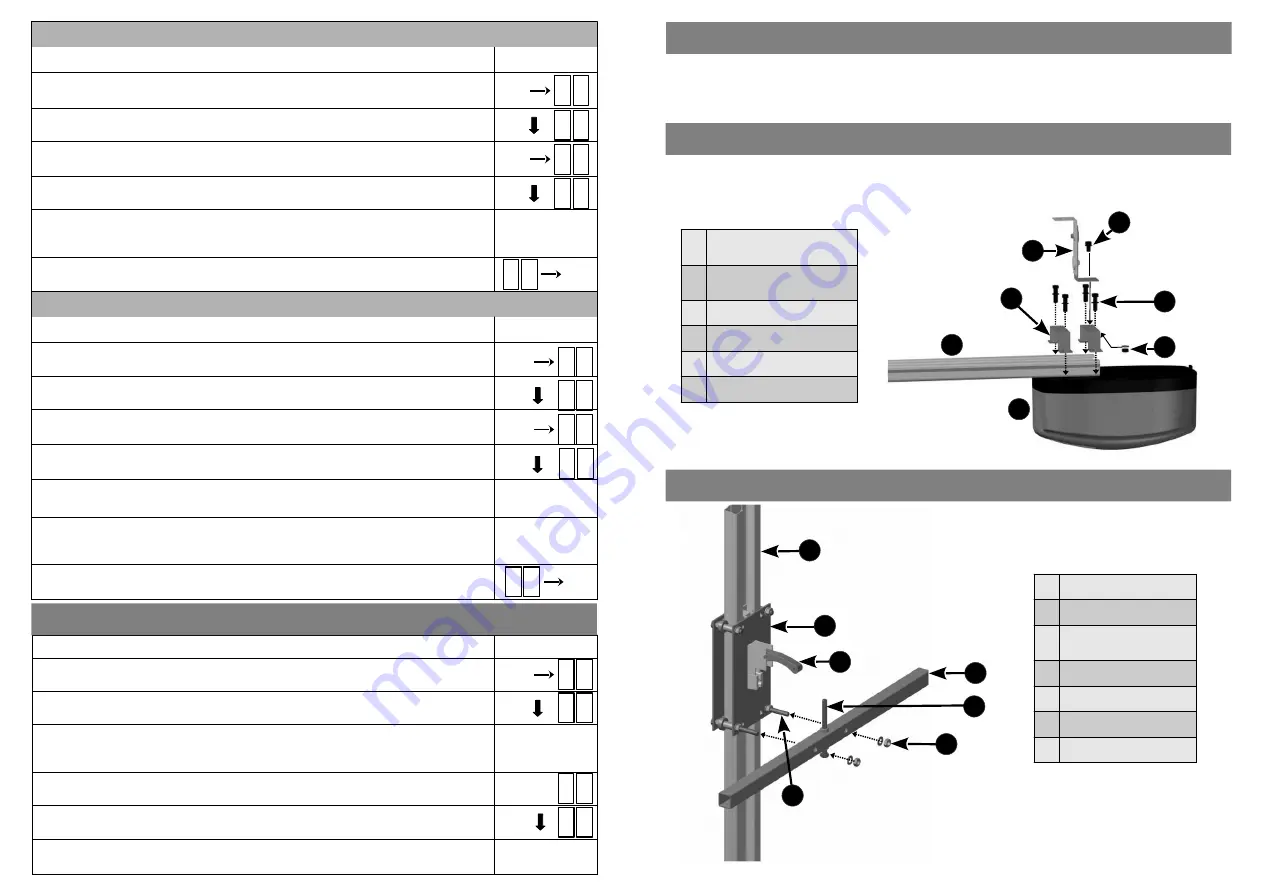

ATTACHING THE POWER HEAD TO THE DRIVE CHANNEL

ATTACHING THE CROSS TUBE TO THE DRIVE CHANNEL

A ach the Power Head to the Drive Channel using the U-Brackets and the four M6 x 25mm hex bolts and

washers provided.

A ach the Floa ng Bracket to the top most U-Bracket (as shown below) using the M6 x 12mm bolt, nut and

washer.

1

M6 x 12mm

Hex Bolt, Nut & Washer

2

M6 x 25mm

Hex Bolts & Washers

3

Floa ng Bracket

4

U-Brackets

5

Drive Channel

6

Power Head

1

Drive Channel

2

Li ing Assembly

3

Manual Release

Mechanism

4

Cross Tube

5

Adjustable End Stop

6

M8 Nut & Washer (x2)

7

M8 Bolt (x2)

The LUX DC12 Ver cal Mount Roll Up Operator is used to operate either single or double roll up garage doors. If a

single door is to be automated, the drive channel will be mounted on either the le or right hand side of the door.

If two doors are being automated, the drive channel will be mounted in the middle, between the two doors.

VERTICAL MOUNT ROLL UP DRIVE CHANNEL POSITION

7