Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

80

2.

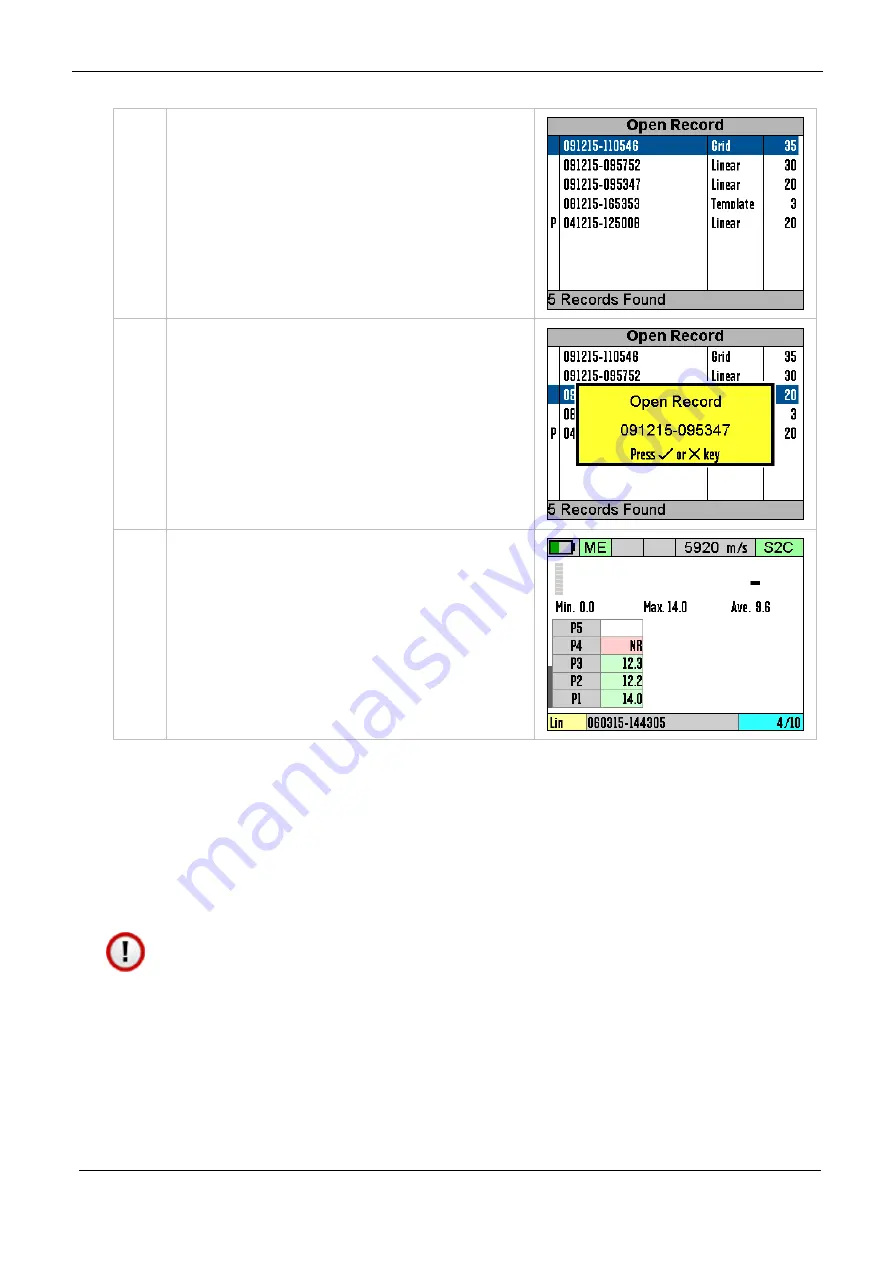

Select the Record to open, the

most recent is at the top of the

list.

Confirm by pressing the √ key.

3.

Confirm by pressing the √ key.

4.

The record has been opened and

data logging record has been

resumed.

Protecting a Record

If you want to Protect a record from being deleted or modified

then you can use the Protect Record feature. Once protected

records cannot be deleted from the gauge and they cannot be re-

opened and amended or changed.

Once you protect a record then you will be unable to un-

protect the record from the gauge. You can however remove

the SD card and deleted the record files from the SD card

using a computer.