15

Ed. 0121 - 70702601 REV00 Rounding machine - Preinstallation

Problems during use

During use, some problems may occur that can be easily solved following the instructions detailed below.

PROBLEM FOUND

PROBABLE CAUSES

SOLUTIONS FOR THE USER

The dough balls stick to the auger and find it

difficult to get back up

The dough is too hydrated

Use doughs with hydration from 50 to 65%. If you use doughs with higher hydration (up to 70%

maximum), to obtain good results we recommend you use the dough at 10°C (50°F)

Dough balls do not stick to the auger but

find it difficult to get back up

The dough is not very hydrated

Use doughs with hydration from 50 to 65%. If you use doughs with higher hydration (up to 70%

maximum), to obtain good results we recommend you use the dough at 10°C (50°F)

The dough was left in the air for a long time and

dried up

Once the dough is portioned, start rolling quickly

The portion of dough that goes into the auger

is too large

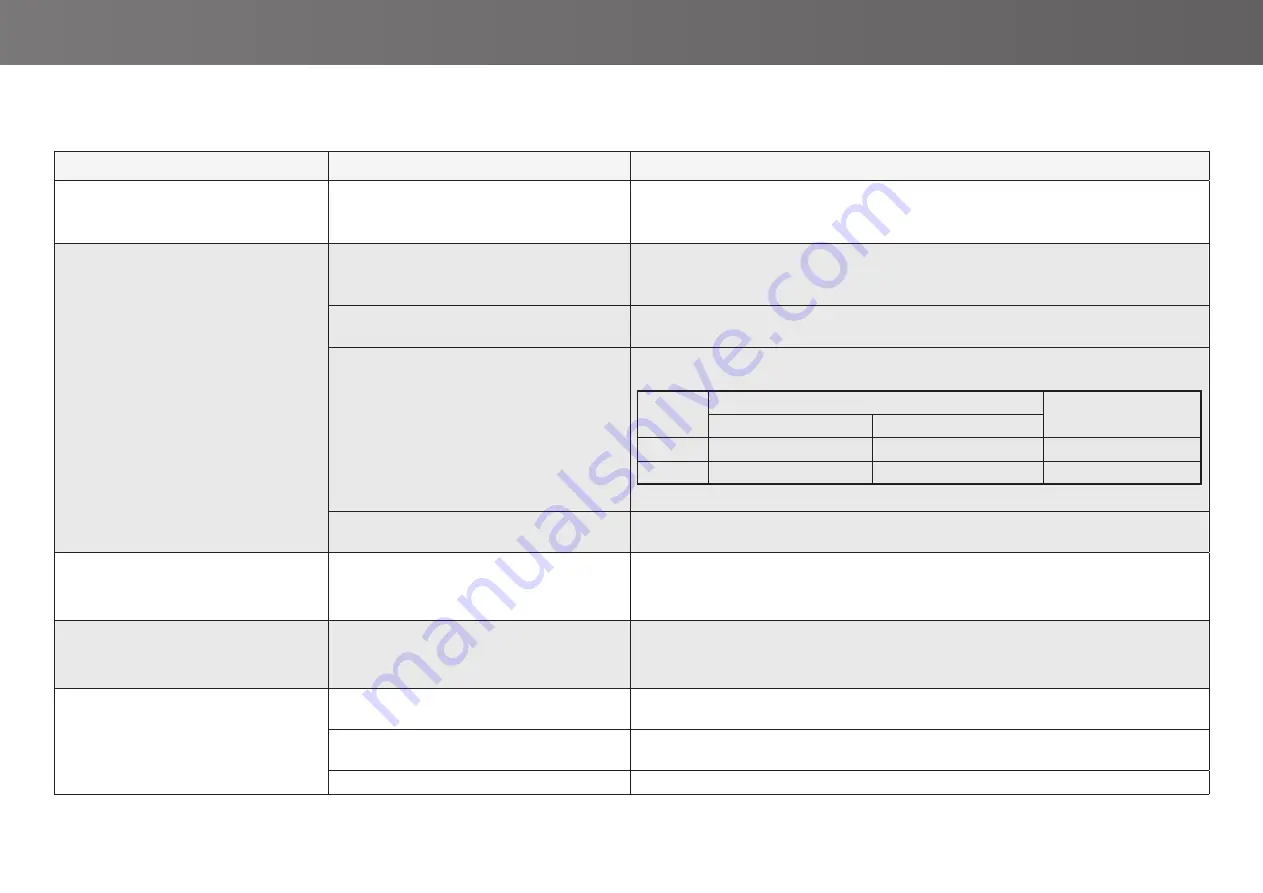

Comply with the following instructions:

Model

Portion weight

Dough hydration

Minimum

Maximum

RND280

20 g [0.044 lb / 0.70 ounces] 300 gr [0.66 lb / 10.58 ounces]

from 50% to 65%

RND800

20 g [0.044 lb / 0.70 ounces]

900 gr [1.9 lb / 31.7 ounces]

from 50% to 65%

The portions of dough were floured before

being inserted into the auger

Do not flour the dough portions

The rounded ball is much larger than the

amount of dough inserted

The portions of dough were inserted too quickly

one after the other inside the auger and joined

together

Increase the time between inserting one portion of dough and the next

The surface of the ball formed is not

smooth and has imperfections

The dough did not rest long enough before

portioning

Increase the resting time of the dough before portioning it

After pressing the ON/OFF button, the ma-

chine does not start

The appliance has been stopped pressing the

emergency button

To reset the normal operating conditions, unlock the emergency button rotating it clockwise

and restart the machine with the ON/OFF button

The machine is not powered

Make sure that the plug is correctly inserted into the socket and that there are no interruptions

to the electricity supply (e.g. black-out)

Some component is broken

Contact the Dealer