To maintain efficient grinder pump operation, care should

be taken to keep both the radial cutter (4) and shredding

ring (16) cutting edges sharp. Neither part can be

sharpened to renew the cutting ability. The radial cutter (4)

must be replaced and the shredding ring either reversed

or replaced.

E-1.2) Reassembly:

To replace impeller (14) on shaft, turn clockwise while

holding shaft stationary with a screwdriver. Next install

shredding ring (16) by pressing into body (19) with the use

of an arbor press.

NOTE:

It is important that the grooves

in the shredding ring are at the top of the pump and the

solid part is to the bottom. This is to keep some solids from

setting in the grooves and causing a jam at start up. Then

insert throat (17) into body (19) with three flat head allen

screws (18). Apply a thin coat of petroleum jelly to the

square ring (20) and place on body (19). Place motor

assembly on body (19), being careful not to damage

square rings (20). Place washers (9) and nuts (21) on studs

(22) and tighten. Screw radial cutter (4) on shaft clockwise.

Hold motor shaft stationary with screwdriver and tighten.

Then replace washer (5) and screw (6). Radial cutter (4)

to be flush with shredding ring (16) on suction side to within

±

.020.

E-2) SHAFT SEAL SERVICE:

CAUTION ! - Handle seal parts with extreme

care. DO NOT scratch or mar lapped surfaces.

E-2.1) Disassembly and Inspection:

Seal-

To expose shaft seal (12) for examination

disassemble volute, cutter and impeller as outlined in

paragraph E-1.1.

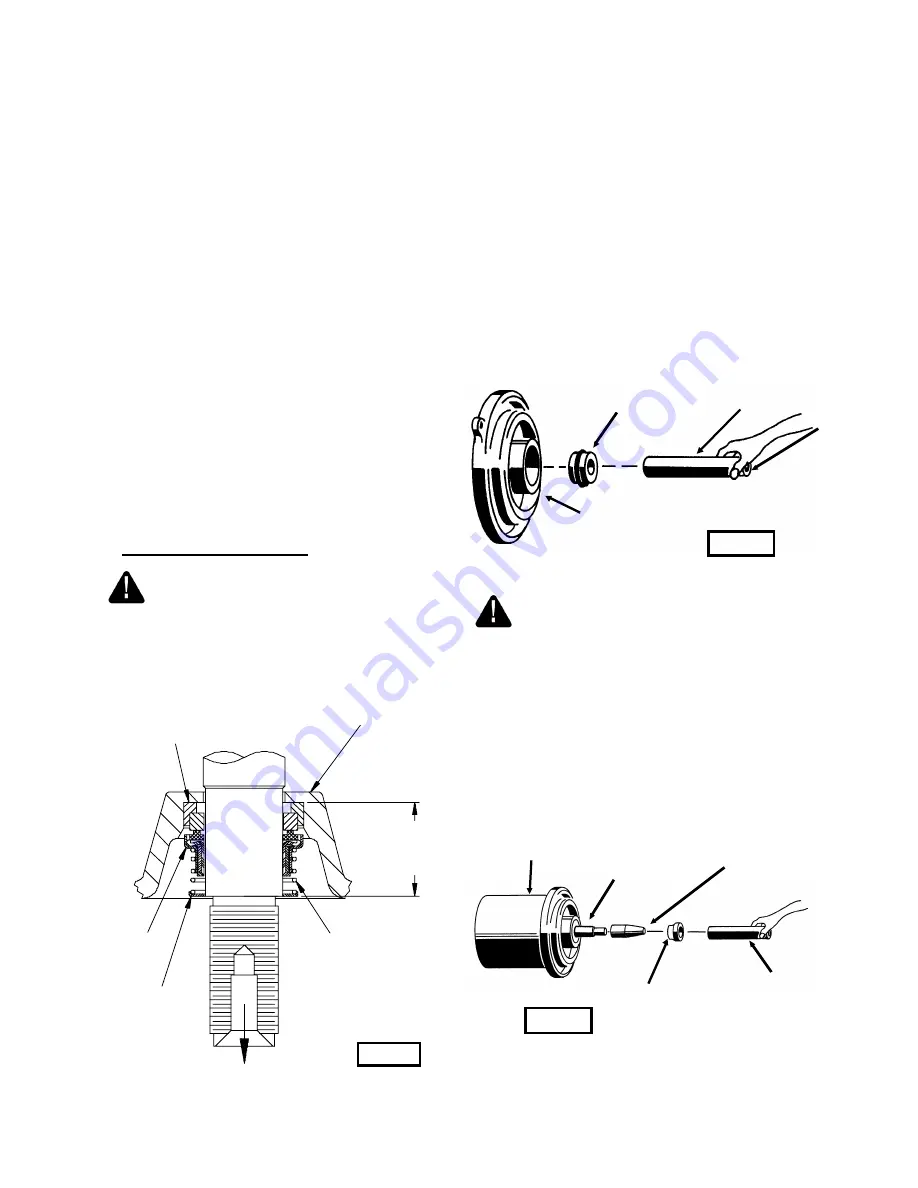

To inspect seal further, remove retaining ring (12d), spring

(12c) and rotating member (12b) from shaft (see Fig. 3).

Examine all seal parts and especially contact faces.

Inspect seal for signs of wear such as uneven wear pattern

on stationary members, chips and scratches on either seal

face.

DO NOT

interchange seal components, replace the

entire shaft seal (12). If replacing seal, remove stationary

(12a) by prying out with flat screw driver.

E-2.2) Reassembly:

Seal-

Clean and oil seal cavity in seal plate (10). Lightly oil

(

DO NOT

use grease) outer surface of stationary member

(12a). Press stationary member (12a) firmly into seal plate

(10), using a seal pusher (see parts list- seal tool kit).

Nothing but the seal pusher is to come in contact with seal

face (see Fig. 4).

IMPORTANT ! - DO NOT HAMMER ON THE

SEAL PUSHER- IT WILL DAMAGE THE SEAL

FACE.

Make sure the stationary member is in straight. Slide a

bullet (see parts list-seal tool kit) over motor shaft. Lightly

oil (

DO NOT

use grease) shaft, bullet and inner surface of

bellows on rotating member (12b) (see Fig. 5). With lapped

surface of rotating member (12b) facing inward toward

stationary member (12a), slide rotating member (12b) over

bullet and onto shaft, using seal pusher, until lapped faces

of (12a) and (12b) are together (see Fig. 3).

PUMP END

(OUTBOARD END)

SEAL

ASSEMBLY

(12)

Seal Plate (10)

Fig. 3

MOTOR END

(INBOARD END)

Stationary (12a)

Rotating

Member

(12b)

Retaining Ring

(12d)

Spring (12c)

Seal Plate (10)

SEAL PUSHER

Stationary Member (12a)

Polished Face Out.

Fig. 4

MOTOR & SEAL

PLATE

STATIONARY

(12a)

BULLET

ROTATING

MEMBER

(12b)

SEAL PUSHER

Fig. 5

8