16 - ENG

D20396

PROBLEM

CAUSE

CORRECTION

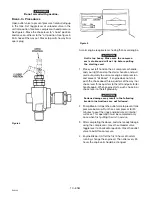

EXCESSIVE VIBRATION COULD

WEAKEN THE AIR TANK AND CAUSE IT

TO RUPTURE OR EXPLODE. STIFFENER

BAR NUTS AND MOUNTING SCREWS

MUST BE KEPT TIGHTENED. NEVER

OPERATE THE OUTFIT UNLESS

EQUIPPED WITH THE STIFFENER BAR

AND RUBBER FEET.

Stiffener bar or engine and compressor

mounting screws are loose.

Excessive vibration.

Excessive belt wear.

Squealing sound.

Engine will not run

Loose belt.

Adjust tension per instruction on page 12, step 5.

Pulley misalignment.

Adjust pulleys per instructions on page 13.

Loose pulley.

Loose belt.

There is no oil in the compressor.

The stop switch is in the "stop" position.

The gasoline tank is empty.

The choke is not set properly.

Improper fuel mixture.

Air tank pressure is too high.

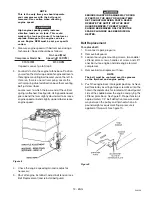

The unloading valve toggle lever is in a

horizontal position.

Check for worn keyway or pulley bore. Also check

for bent motor shaft. Replace parts if necessary.

Adjust belt tension per instructions on page 12,

step 5.

Add oil to top of fill hole in base.

Move the stop switch away from the spark plug.

Fill the tank with gas.

Re-set the choke. Remember, a warm engine

requires less choking that a cold engine.

Adjust the fuel mixture.

Open the ball valve and reduce tank pressure to less

than 40 psig.

Place unloading valve toggle lever in a vertical

position.