■

Install inrush current limiting resistor(TFR1) between R terminal and +BC terminal.

■

If TFR1 is not connected, the power supply will not work.

■

The surge capacity is required for TFR1.

■

Wirewound resistor with thermal cut-offs type is required.

■

Inrush current limiting resistor can be used to limit the primary inrush current. However,

the secondary inrush current can’t be limited by increasing the resistor value of inrush

current limiting resistor. The secondary inrush current is approx. 25 ~ 30A.

Therefore, we don’t recommend connecting a large resistance as TFR1.

■

The inrush current changes by PCB pattern, parts characteristic etc.

Check the actual inrush current value flowing through the AC line.

Table 2.5

Recommended

resistor TFR1

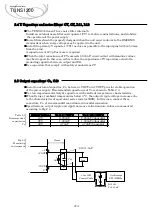

■The selection method of TFR1 is shown below.

・

Calculation of resistance

Resistance can be calculated using the following formula.

TFR1

:

Inrush current limiting resistor

RL

:

Line impedance

Vin

:

Input voltage (rms)

Ip

:

Primary Inrush current (peak)

・

Calculation of required surge capacity

Required surge capacity can be calculated using the following formula.

Please contact to the component manufacturer regarding the surge current

withstanding capability.

I2t

:

Current squared times

TFR1

:

Inrush current limiting resistor

Cbc

:

Smoothing capacitor for boost voltage

Vin

:

Input voltage (rms)

■

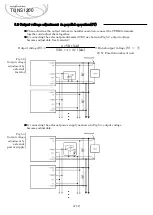

If you need to meet the safety standards, install a discharging resistor R1 at input

interphase capacitors.

■

Please select a resistor so that the input interphase voltage decreases in 42.4V or less

at 1 second after turn off the input.

■

Fig.2.7 shows the relationship between a necessary resistance of R1 and total capacitance

of input interphase capacitors. The data is the value assuming the worst condition.

■

Please keep margin for rated voltage and power of R1.

Fig.2.7

Relationship

between input

interphase

capacitors

and discharging

resistor R1.

2.8 Inrush current limiting resistor: TFR1

2.9 Discharging resistor: R1

A-7

Recommended resistance

4.7Ω

~

22Ω

Applications Manual

TUNS1200

]

[

2

1

−

=

L

R

Ip

Vin

TFR

0

50

100

150

200

250

300

350

400

450

500

0

1

2

3

4

5

6

7

8

9

10

R

1

[

kΩ

]

Total capacitance of input interphase capacitors

[μF]

100VAC

200VAC

277VAC

]

[

1

2

2

2

s

A

TFR

Vin

Cbc

t

I

=