© Copyright, Core Protection Systems Ltd, 2021

Page 14

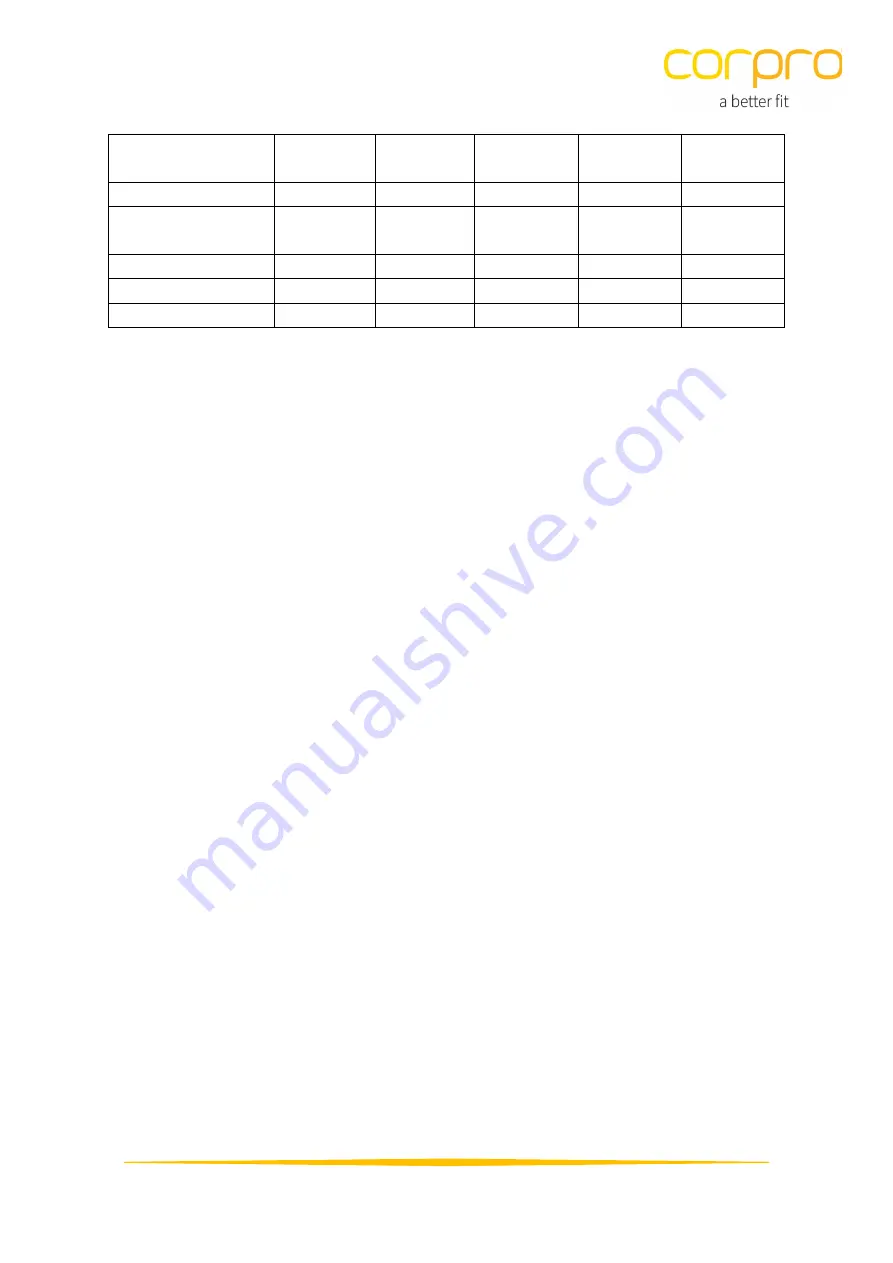

Interval

Task

Before Use

After Use

3 months

6 months

12 months

Cleaning/Disinfecting

X

X

Fit Test / Leak

Tightness Test

X

(First Use)

X

Valve Replacement

X*

X*

X*

General User Checks

X

X

Fit Check

X

X

As previously mentioned, depending on your environment, risks and wear frequency, certain

maintenance tasks may be required more frequently. This needs to be established by an

organisational risk assessment.

If components have been replaced (e.g., valves), a fit check and a general user check must be carried

out in advance of mask’s next use.

All aforementioned tasks should be performed if a mask has been in storage for a long period, and at

least once a year.

* Either every 3, 6 or 12 months depending on wear frequency and working environment.

Organisational risk assessment required to establish.

3.1.6 Disposal

To establish the safest disposal method for the HM1400, this will require a risk assessment by your

organisation. However, Corpro can provide the following information and recommendations:

•

All parts of the mask, other than the elastic strap, are recyclable as the mask’s materials

include thermoplastic elastomers (TPE), acrylonitrile butadiene styrene (ABS) or

polycarbonate/acrylonitrile butadiene styrene (PC/ABS) plastic, and silicone (valves only).

•

Depending on your working environment, you may not be able to recycle the materials as the

mask may be classed as hazardous waste. This would need to be checked and, if classed as

hazardous waste, the appropriate disposal method should be outlined and followed.

•

If the mask is not classed as hazardous waste, the product should be disposed of or recycled

as applicable in a controlled waste area at the occupational site / an agreed third-party site.