Page 4

SRP 003-304 • Issue 9 • July 2004

7.

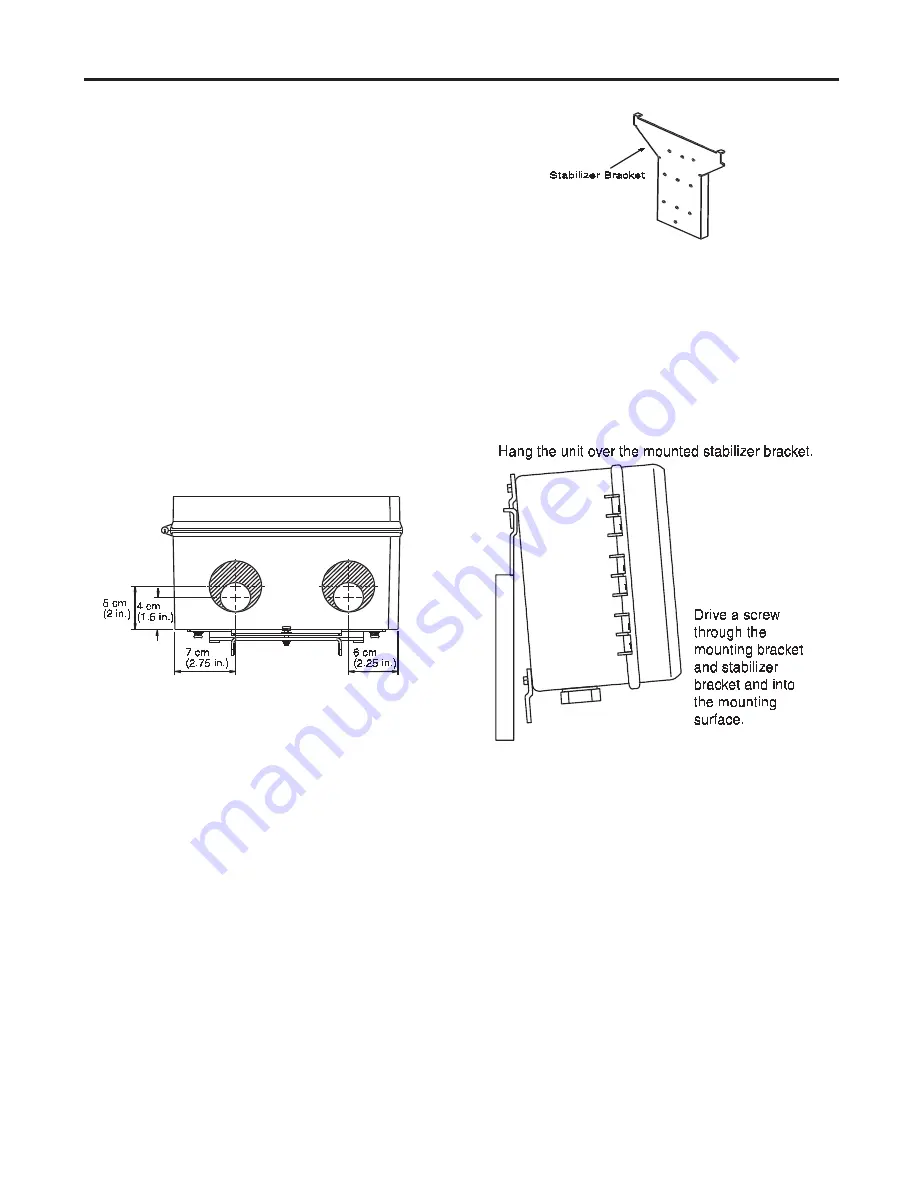

Installing Holes

IMPORTANT:

Remove the base plate from the

housing before cutting any holes.

7.1

Determine the size hole needed based on

the fitting being used. Measure and mark the

location of the hole centers, based on

dimensions in Figure 3, on the bottom of the

unit. The 2-inch conduit holes are represented

by the larger circles and the 1-inch conduit

holes by the smaller circles.

7.2

Cut holes as required for your coupling

fitting. Follow local safety practices.

7.3

Install the fittings (purchased separately).

Fitting kits are available in three types. The kit

is dependant on the type of fitting desired for

your application.

7.4

Reinstall the base plate.

8.

Mounting

NOTE:

If you will be mounting the EDC without

the stabilizer bracket, remove and discard the

stabilizer bracket. Rotate the top bracket so the

elliptical hole is exposed. Position the housing as

desired and secure using

1

/

4

-inch screws in the top

and bottom brackets.

8.1 When wall-mounting,

a) Remove the stabilizer bracket (Figure 4).

b) Drive

1

/

4

-inch screws or wall anchors

through the stabilizer bracket and into the

mounting surface.

Do not install a screw in the

bottom hole of the stabilizer bracket at this time.

c) Hang the unit on the stabilizer bracket,

ensuring that the top mounting bracket is

resting between the two tabs on the

stabilizer bracket (Figure 5).

8.2 When the EDC will be mounted onto a

utility pole:

a) Secure the stabilizer bracket to the pole

using

1

/

4

-inch screws.

Do not install a screw

into the bottom bracket at this time.

b) Hang the EDC on the stabilizer bracket,

ensuring that the top mounting bracket is

resting between the two tabs on the

stabilizer bracket.

c) Line up the elliptical hole in the bottom

mounting bracket with the bottom hole in

the stabilizer bracket. Drive a

1

/

4

-inch screw

through the brackets and into the utility

pole.

d) Mounting hardware is not provided.

Figure 3

Figure 4

Figure 5

d) Align the elliptical hole in the bottom

mounting bracket and the bottom hole in

the stabilizer bracket. Install a

1

/

4

-in. screw

through the holes into the mounting

surface.

e) Mounting hardware is not provided.