4.5 Piston Rod Packing Adjustment

Piston rod packing should be adjusted or replaced

whenever leakage becomes noticeable. Adjust packing

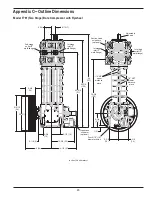

by tightening packing nuts as shown in Figure 4.5.

Figure 4.5: Packing adjusting nuts (models T791 and T891 only)

NOTE: Compressor models D791 and D891 do not

have adjustable packing nuts so the packing sets on

models D791 and D891 are not adjustable, the piston

rod packing should be replaced whenever leakage

becomes noticeable.

Typically, it is a good idea to replace piston rod packing

and piston rings at the same time. For instructions on

replacing the piston rod packing, see section 4.6.

4.6 Cylinder and Packing

Replacement

Cylinders very seldom require replacement if the

compressor is properly maintained. The primary cause

of damage to cylinders is corrosion and the entry of

solid debris or liquid into the compression chamber.

Improper storage can also result in corrosion damage to

cylinder (for proper storage instructions see chapter 5).

If the cylinder does become damaged or corroded, use

a hone to smooth the cylinder bore and then polish it

to the value shown in Appendix B. If more than .005 of

an inch must be removed to smooth the bore, replace

the cylinder. Cylinder liners and oversized rings are

not available. OVERBORING THE CYLINDER WILL

RESULT IN GREATLY REDUCED RING LIFE.

Many compressor repair operations require removal of

the cylinder. While the compressor is disassembled,

special care should be taken to avoid damage or

corrosion to the cylinder. If the compressor is to be left

open for more than a few hours, bare metal surfaces

should be coated with rust preventative.

When reassembling the compressor, make sure the

bolts are retightened using the torque values listed in

Appendix B.

Packing Replacement Instructions

For specific construction details and actual part numbers,

consult Appendix E in the back of this Installation,

Operation & Maintenance (IOM) manual. Use instructions

below and on the following pages that apply to the

MODEL and SERIAL NUMBER of your compressor. Be

careful to arrange packing sets in the proper order.

CAUTION: Before installing the new piston rod

packing, bleed all pressure from the compressor and

piping and purge if necessary. After the new piston

rod packing has been installed, the unit should be

pressure tested and checked for leaks at all joints

and gasket surfaces. When the compressor is being

used with toxic, dangerous, flammable or explosive

gases, this pressure and leak testing should be done

with air or a dry, inert gas such as nitrogen.

Cleanliness:

Sealing a reciprocating piston rod is a very difficult

task. Keep all parts, tools and your hands clean during

installation. Your new packing needs every chance it can

get, so keep it clean.

Workmanship:

Your Corken compressor is a precision piece of equipment

with very close tolerances. Treat it as such. Never beat

on it to get parts in or out.

Packing Configuration

The packing for these compressors includes segmented

packing in a packing barrel at the lower end of the

cylinder and V-ring packing in a packing box cartridge

below the segmented packing.

Refer to Appendix E for packing assembly details. Note

the arrangement of the particular packing sets for the

model of machine that you have.

4.6.1 Model D791 and D891 Compressors (D-Style)

On Models D791 and D891, there is one set of V-ring

packing in a packing box cartridge attached to the

packing barrel. The packing box cartridge holds the

segmented packing inside the barrel.

Disassembly of Packing (D-Style)

1. Depressurize and open the compressor.

2. Remove the cylinder cap, heads, pistons and cylinder.

3. Remove the packing barrels by prying upwardly under

each one and lifting entire packing barrel/cartridge

assembly up from piston rod.

14