31

COMUNELLO

®Copyright 2016 - All rights reserved

ENGLISH

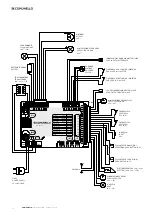

ANT-:

Antenna Ground Input.

ANT+:

Antenna Hot pole input.

CN3:

ENC1 +:

Operator 1 Encoder Power Input

ENC1 E:

Operator 1 Encoder Signal Input

ENC1 GND:

Common GND input

MOT1 FCA:

Operator 1 Opening Limit Switch Input (NC).

MOT1 FCC:

Operator 1 Closing Limit Switch Input (NC).

SYNC D:

Master/Slave Synchronisation Input (Data)

SYNC GND: Master/Slave Synchronisation Input (GND)

CN8:

L:

230 V~ line input (phase).

N:

230 V~ line input (neutral).

• Connection of the Y power cord.

10.3 FUNCTIONAL CHARACTERISTICS

OPERATION:

When either the remote or the low voltage pushbutton panel are used to

control the barrier, operation is as follows:

the first command opens the barrier until motor time elapses or the arm

reaches its opening limit position; the second command closes the barrier;

if another command is transmitted during the Opening movement, the

control unit disregards the command; if a command is transmitted during

the Closing movement the control unit reverses the movement direction.

AUTOMATIC CLOSING:

The control unit can be set up to close the barrier automatically without

sending any additional commands.

Selection of this type of operation is described in Pause time programming

mode.

EMERGENCY STOP INPUT:

The control unit allows the connection of an emergency stop pushbutton

(NC). Pressing this pushbutton irrespective of the current operating mode

of the control unit will cause barrier movements to stop immediately. An

additional barrier movement command will be valid, provided the emergency

stop input is deactivated and, in any case, the control unit will perform the

barrier opening cycle after preflashing for 5 seconds.

Important: in Master/Slave applications, if you want to stop the Barriers

simultaneously, the Emergency Stop Inputs of the Master and Slave control

units must be interconnected.

PHOTOCELLS:

Photocells can be powered by and connected to the control unit in

accordance with directive EN 12453.

• Input DS1 (NC)

Tripping of the photocells during opening is disregarded, while during

closing it causes reversal of the direction of movement.

• Input DS2 (NC)

Tripping during opening causes momentary stopping of the barrier; once

the photocell is freed, the control unit resumes the opening movement.

Tripping during closing causes reversal of the direction of movement.

IMPORTANT:

in Master/Slave applications tripping of input DS2 causes

exclusively reversal of the direction of movement in the closing stroke.

OPENING AND CLOSING LIMIT SWITCHES:

The control unit allows the connection of Opening and Closing limit

switches (NC). Tripping of the limit switches in the associated operating

cycles causes immediate stopping of barrier movement.

ADJUSTMENT OF MOTOR FORCE DURING THE “NORMAL” CYCLE:

The electronic control unit is equipped with a “SPEED” trimmer for

adjustment of Motor Force during the Normal cycle.

Adjustment can be performed in a range of between 50% and 100% of

maximum force during the Normal cycle.

ADJUSTMENT OF MOTOR FORCE DURING THE “SLOWDOWN”

CYCLE:

The electronic control unit is equipped with a “SLOWING” trimmer

adjustment of Motor Force during the Slowdown cycle.

Adjustment can be performed in a range of between 50% and 100% of

maximum force during the Slowdown cycle.

OBSTACLE DETECTION:

The electronic control unit is equipped with a “SENS” trimmer, completely

managed by the microprocessor, for adjustment of the opposing Force

required to detect the presence of an obstacle.

The adjustment can be made with a trip time from a minimum of 0.1

seconds to a maximum of 1 seconds

IMPORTANT:

detection of an obstacle always causes a reversal of the

direction of movement.

MOTOR ENCODER:

The control unit allows connection of an Encoder. The use of Encoders

facilitates the work of the control unit in the Obstacles Detection function

and ensures enhanced precision during execution of arm movements.

FLASHING LIGHT:

The control unit features an output to control a 24 V 25W max flashing

light. Operation of the flashing light depends on the movement of the motor

and automatic closing, which, if selected, enables the flashing light also

during the pause time.

INDICATOR LIGHT:

The control unit allows a 24 V indicator light to be connected to display

the status of the automation system.

Indicator light off: barrier closed

Indicator light on: barrier open

Indicator light slow blinking: opening movement; rapid blinking: closing

movement.

OPERATION WITH TIMER:

The control unit allows a timer to be connected in place of the open – close

pushbutton.

E.g.: at 08.00 am the timer closes the contact and the control unit

commands an opening movement; at 06.00 pm the timer opens the

contact and the control unit commands a closing movement. From 08.00

am – 06.00 pm at the end of the opening cycle the control unit disables the

flashing light, automatic closing and the remotes.

BUFFER BATTERY:

The control unit is equipped with a built-in 27.4 V battery charger to

keep a full charge on the two 12V batteries connected in series. The

batteries allow the barrier to perform several complete open/close cycles

in emergency mode. The Flashing Light and LED strip output will operate

only for the first 4 seconds of the movement when mains power is absent.

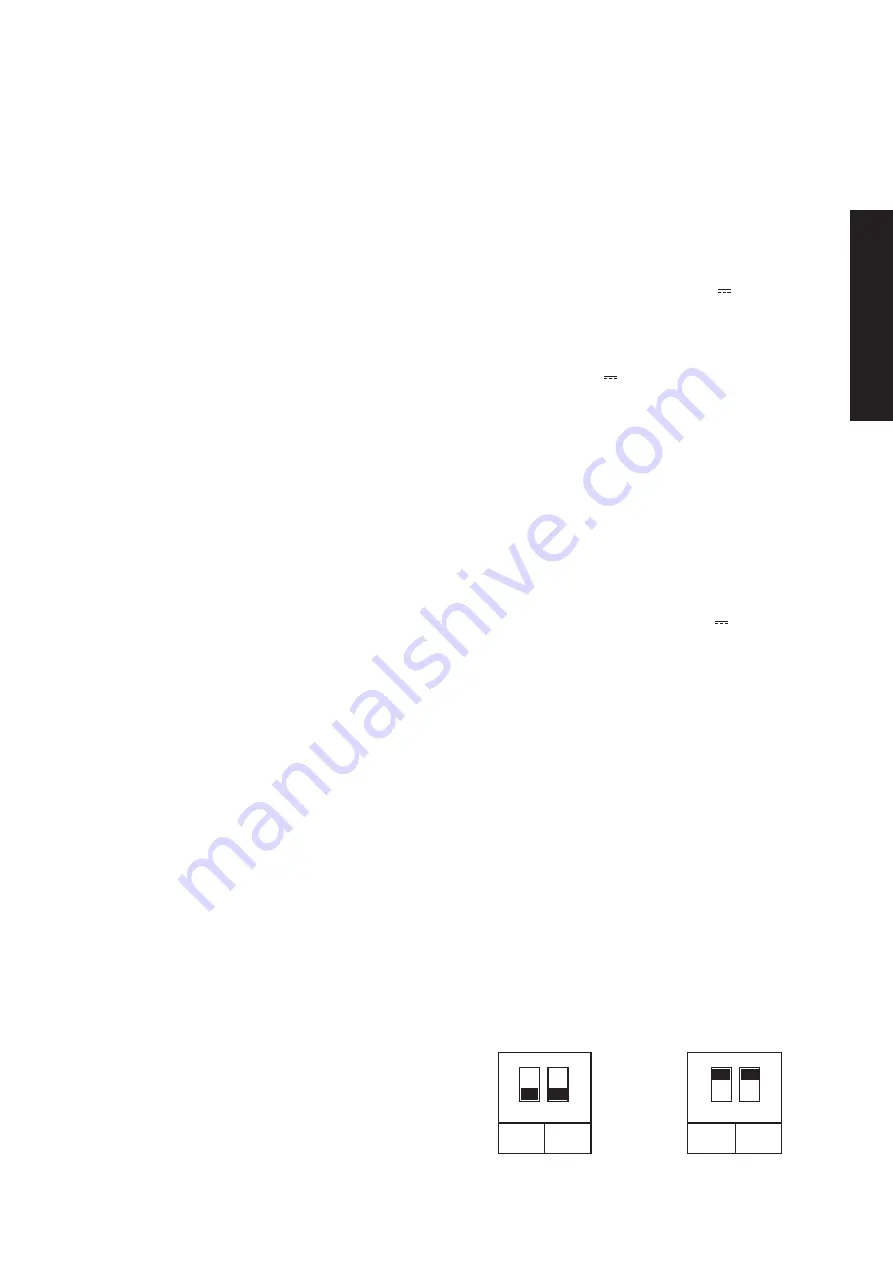

CHECKING THE MOTOR DIRECTION OF RUN

AND MASTER/SLAVE SELECTION

Important Note: make sure the settings of dip-switch SW1 are

changed with the control unit off and then repeat the control unit

programming procedure.

The electronic control unit is equipped with a Dip Switch SW1, which can

be used to change the direction of run of the connected motor without

having to physically alter the electrical connections (DIP 1). In addition, again

using (DIP 2) of Dip Switch SW1, in the case of synchronized operation of

two barriers the control unit can be used to select which one acts as Master

and which one acts as Slave.

Important Note:

• In Master/Slave applications synchronised opening of the barrier is

available using the PUL input or exclusively the master barrier using the

PED input.

• In the Slave control unit all the control and safety inputs (except the

Emergency stop input) are automatically disabled because they are

managed by the control unit configured as the Master.

INV

1

ON

2

OFF

MASTER

INV

ON

SLAVE

1

ON

2

SW1

SW1

Summary of Contents for LIMIT 500

Page 3: ...3 COMUNELLO Copyright 2016 All rights reserved FIG 2A FIG 2B FIG 3 FIG 4 FIG 3B FIG 5...

Page 5: ...5 COMUNELLO Copyright 2016 All rights reserved FIG 7A FIG 7B FIG 8A FIG 8C FIG 8B FIG 9A...

Page 7: ...7 COMUNELLO Copyright 2016 All rights reserved FIG 13A FIG 13B FIG 14A FIG 14B...

Page 8: ...8 COMUNELLO Copyright 2016 All rights reserved FIG 16A FIG 16B FIG 15...

Page 9: ...9 COMUNELLO Copyright 2016 All rights reserved FIG 17 FIG 18A FIG 18B...

Page 10: ...10 COMUNELLO Copyright 2016 All rights reserved DEFLECTOR FIXING FIG 20A...

Page 14: ...LIMIT 800 SWING DOWN SUPPORT 45 MIN FIG A FIG C FIG B...

Page 16: ...LIMIT 600 BAR AND SKIRT FIG A FIG C FIG B 110 MIN 110 MIN 200 200...

Page 68: ...NOTES...

Page 69: ...69 COMUNELLO Copyright 2016 All rights reserved NOTES...

Page 70: ...NOTES...

Page 71: ...71 COMUNELLO Copyright 2016 All rights reserved NOTES...