F

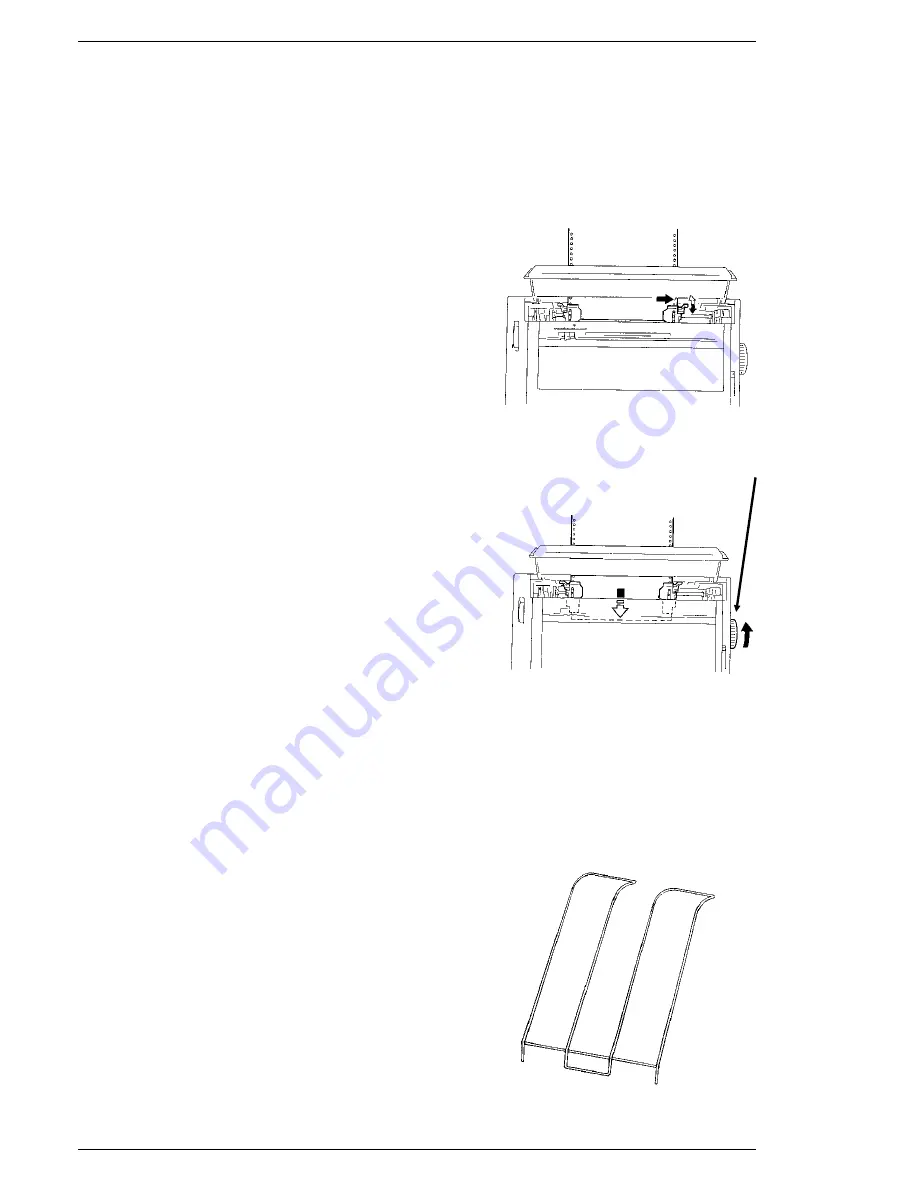

Make sure that the paper is correctly aligned with the left and right

tractors.

4.

Close the left and right tractor

covers.Slide the right tractor to

take up any slack in the paper.

Move the tractor set lever of the

right tractor to lock the tractor.

5.

Rotate the platen knob to feed the

paper forward slightly as shown

below.

When loading chemical multicopy fanfold paper in push tractor you should

install the fanfold paper guide

Proceed as follows:

1.

Find the fanfold paper guide

Platen knob

Chapter 3

3.28

A78401740-001

Summary of Contents for 914N

Page 1: ...914N User Manual...

Page 2: ......

Page 3: ...Compuprint 914N...

Page 4: ......

Page 10: ......

Page 12: ...Getting To Know Your Printer Chapter 1 1 2 A78401740 001...

Page 16: ...Rear View Interface Connector Friction Release Lever Rear Cover Chapter 1 1 6 A78401740 001...

Page 70: ......

Page 76: ......

Page 89: ...Commands Appendix A A78401740 001 A 5...

Page 120: ......

Page 122: ...Character Sets Character Set 1 CS1 Appendix B B 2 A78401740 001...

Page 123: ...Character Set 2 CS2 Appendix B A78401740 001 B 3...

Page 124: ...IBM PC Character Set All Printable Character Table Appendix B B 4 A78401740 001...

Page 125: ...IBM National Variations USA CP 437 Appendix B A78401740 001 B 5...

Page 126: ...Multilingual CP 850 Appendix B B 6 A78401740 001...

Page 127: ...Portugal CP 860 Appendix B A78401740 001 B 7...

Page 128: ...Canada France CP 863 Appendix B B 8 A78401740 001...

Page 129: ...Denmark Norway CP 865 Appendix B A78401740 001 B 9...

Page 130: ...EPSON National Variations Appendix B B 10 A78401740 001...

Page 132: ......

Page 140: ......

Page 146: ......