FIGURE 4-10. SPOT TIME CONTROL

FUNCTION SELECTOR:

Place the switch in the position ( I ) activate the function:

1.- Dotting: Welding by time intervals, the duration of each interval (from when the torch trigger

is pressed) will depend on the position pre-set in the control of the spot time.

SPOT TIME CONTROL. This control allows you to adjust the tapping time (duration of

the operation or welding interval) from 0.5 to 4 seconds. Turning the knob clockwise

increases the time. The scale of the control is calibrated in percentage and does not

indicate the interval time.

Install and

connect the

equipment

Turn On Wire feeder

and Power Source

Put On

sa fety

equipment

Install and

prepare Flux

system

Install and

prepare

wire feeder

Set Control

Turn On Flux

system

Beging welding

Readjsut

controls and

begin welding

O pen

gas

valve

Turn On Wire

feeder and Power

Source

Put On

sa fety

equipment

Install and

prepare

wire feeder

Install and

connect the

equipment

Readjsut

controls and

begin welding

Put On

sa fety

equipment

Install and

prepare

wire feeder

Install and

connect the

equipment

Turn On Wire

feeder and Power

Source

Set Controls

Put On

sa fety

equipment.

Select

coa t

electrode

Connect

compreser air

system

Inssert electrode into

tor ch

Supply

compresed air

Turn On Power

Source

Start cutting or

gouging

Install and

connect the

equipment

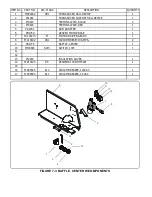

AIR CUTTING AND GOUGING PROCESS (CAC-A)

9

FIGURE 4-11 OPERATION SEQUENCE FOR GMAW, FCAW, SAW, CAC-A

SUBMERGED ARC PROCESS (SAW)

FLUX CORED ARC WELDING PROCESS (FCAW)

SOLID WIRE PROCESS (GMAW)