Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Combustion Research Corporation

Page 13

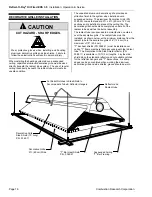

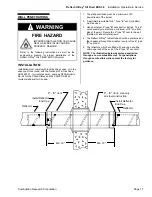

REFLECTOR INSTALLATION

CAUTION

CUT HAZARD - SHARP EDGES.

Wear protective gloves when installing and handling

and cutting reflectors. Failure to follow these

instructions will result in personal injury.

Radiant heat tube combination hangers are an integral part

of the reflector support system. Improperly installed radiant

tube hangers will distort reflectors and result in an

undesirable appearance of the entire system, and can lead

to vibration and noise.

Check to be sure all combination hangers and intermediate

supports are hanging straight. Tubes must be straight and

in line before installing reflectors.

Install reflector elbows and "tees" where required.

1. Starting from burner slide reflector through tube hanger

until end stops against drawband coupler. Nearest the

burner, attach reflector end cap with 4 sheet metal

screws.

2. Adjust position of reflector supports so that reflector is

held level and parallel with heat tube. Where possible,

position one support at overlapped ends of reflectors.

3. Using same procedure, continue to install reflector

sections until entire system is complete. Make sure

each reflector section is overlapped a minimum of 1 -2"

and secured as outlined on this page.

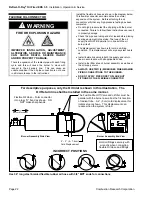

4. When last section of reflector has been installed, inspect

heat tube and reflector assembly as follows:

a. Check to be sure all heat tubes are straight and in

line. Adjust suspension when necessary.

b. Make sure all radiant tube joints are properly

aligned, sealed, and secured.

c. Check all heat tube suspension points, clamps,

turnbuckles, lock nuts, etc. are in place and tight.

All suspension chain should be hanging straight

down.

d. Check all reflector joints for minimum 1 - 2" overlap.

e. Overlapped joints are secured with sheet metal

screws. Make sure expansion joint is in every

straight run - see the following expansion joint

illustration.

f. Check all reflector hangers and supports for location

and make sure reflectors are straight and in line.

g. Make sure all combination hanger hooks are closed.

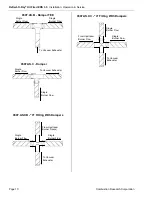

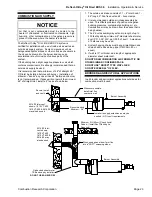

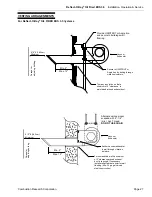

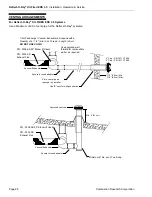

TYPICAL REFLECTOR LAYOUT WITH

EXPANSION JOINTS

An expansion joint consists of a reflector overlap without

being secured together. This allows for freedom of

movement during heat up and cool down. Expansion joints

are to be placed at approximately the center of each straight

run of reflectors with a maximum of three (3) reflectors

connected together. Additional expansion joints in each

straight run may be necessary.

All other reflector joints, reflector elbows and reflector tee's

should be overlapped 1 - 2" and sheet metal screwed

together, DO NOT position an expansion joint at an elbow or

tee.

Burner

Building

Wall

Vacuum

Exhauster

Expansion

Joint

Expansion

Joint

Expansion

Joint

!