Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Combustion Research Corporation

Page 7

SYSTEM INSTALLATION

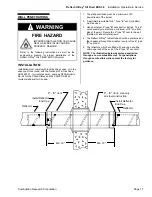

WARNING

COLLAPSE, FIRE AND EXPLOSION HAZARD

Improper suspension of the tube heater may

result in collapse and being crushed. Always

suspend from a permanent and secure part of

the building structure that can evenly support

the total force and weight of entire the heating

system.

Failure to suspend properly and maintain minimum

clearance to combustibles may result in death,

serious injury, fire and/or explosion or property

damage. Always maintain minimum clearances and

post clearance signs where needed.

Combustion Research Corporation recommends that

Reflect-O-Ray

®

Oil Fired OIL FIRED EDS 3.5

®

systems are

hung by means of chain.

DO NOT

STRETCH OR INSTALL

CHAIN OTHER THAN IN A VERTICAL FASHION WHEN

INITIALLY INSTALLED (BURNER NOT FIRING).

WARNING

DO NOT SUSPEND VACUUM EXHAUSTER

BY CHAIN - USE THREADED ROD, ANGLE

IRON, ETC.

If chain is not supplied by Combustion Research

Corporation, furnish a chain with a minimum 90 lb. workload

(trade size #3 or larger).

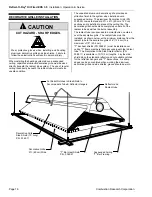

CAUTION

:

This infrared tube system will expand and

contract upon each call for heat and allowances must be

made to accommodate this expansion.

Provisions must be made to limit lateral movement when

systems are installed in site conditions where open doors

may create a wind condition. See page 12 for details.

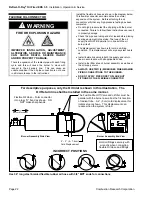

SUSPENSION COMPONENTS - Sub Assembly and

Installation

1. Using the system layout, beginning at the vacuum

exhauster position, determine location of suspension

points of system in relation to building structure, paying

close attention to dimensional limits as shown on page 3.

2. Determine suspension requirements for chain, wire rope,

beam clamps, etc. with the type of mounting hardware

as illustrated. Secure appropriate of each item before

starting installation. Suspension hardware may not be

furnished with this system.

3. If any suspension supports are to be anchored in

cement, drill and insert Acherman-Johnson stud anchors

(or equivalent) as required. DO NOT install anchors in

existing cracks or joints.

4. Determine suspension chain lengths and proceed to cut

and pre assemble suspension components.

NOTE: Each

Reflect-O-Ray

®

OIL FIRED EDS 3.5

burner

assembly is equipped with a suspension point. Adjust as

required to keep the burner assembly level and square to

the radiant tubing.

5. Install beam clamps, eyebolts, etc. at predetermined

suspension locations - refer to the installation layout and

the illustration on page 11 of this manual for guidance.

IMPORTANT NOTE:

If wind or sever air movement can be

encountered in the building (such as found in airplane

hangers where opposing doors are simultaneously open) or

if your area is prone to seismic activity, additional support of

the radiant tube and reflector network will be required. See

page 12 for details

RADIANT TUBE INSTALLATION

The

Reflect-O-Ray

®

OIL FIRED EDS 3.5

radiant heating

system is sealed system. Therefore the heat radiant tubing

installation must be adhered to as outlined in this manual for

optimum performance as designed.

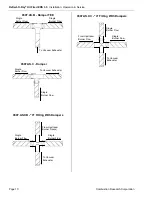

RECOMMENDED HANGER LOCATIONS

For standard systems, the first hanger should be located

approximately 5" from the burner and the next two

combination hangers shall be hung on approximately 56"

centers. The rest of the system combination hangers may

be hung on approximately 9'-10"' centers with intermediate

reflector supports placed halfway between hangers.

For systems using 0304.INSL tubes , the first hanger should

be located approximately 5" from the burner and the next

five (5) combination hangers shall be hung on approximately

56" centers. The rest of the system combination hangers

may be hung on approximately 9'-10"' centers with

intermediate reflector supports placed halfway between

hangers

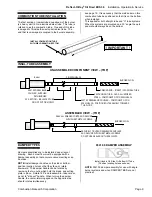

NOTE – THE WELD SEAM ON THIS FIRST (AND

SECOND IF PROVIDED) SECTION OF TUBE MUST BE

POSITIONED SO THAT IT IS ON THE BOTTOM OF THE

TUBE WHEN INSTALLED

.

Weld Seam

Position

Bottom of Tube

Burner Tube End View

Each reflector should be supported at two points, either with

two combination hangers or with one combination hanger

and an intermediate support

NOTE: When a vertical rise of tube is necessary, use a

combination hanger (P/N 0361.00) at both the lower

horizontal run hanger and at the upper horizontal run. If the

vertical run exceeds ten feet (10') a midway support must be

installed. This support may be secured to a wall, beam or

fabricated support. It is recommended that the vertical run

not exceed twenty-five feet (25').

!

!