59

TROUBLESHOOTING

69.

THE MACHINE DOES NOT START

1.

Check the batteries are charged (battery version)

2.

Check the starter battery is charged (combustion engine version)

3.

Check the starter battery is connected to the machine system (combustion engine version)

4.

Check the electric system connector is connected to the battery connector (battery version)

5.

Check the electric system connector is connected to the generator connector (combustion engine

version)

6.

Check the key switch is ON/I

7.

Check there is fuel in the engine tank, and that the LPG cylinder is full (combustion engine version)

70.

THE COMBUSTION ENGINE DOES NOT START

WARNING: If the combustion engine does not start up, check the diagnostics

in the motor use and maintenance manual (the booklet supplied with the

machine itself).

71.

INSUFFICIENT WATER ON THE BRUSHES

1.

Check there is water in the solution tank

2.

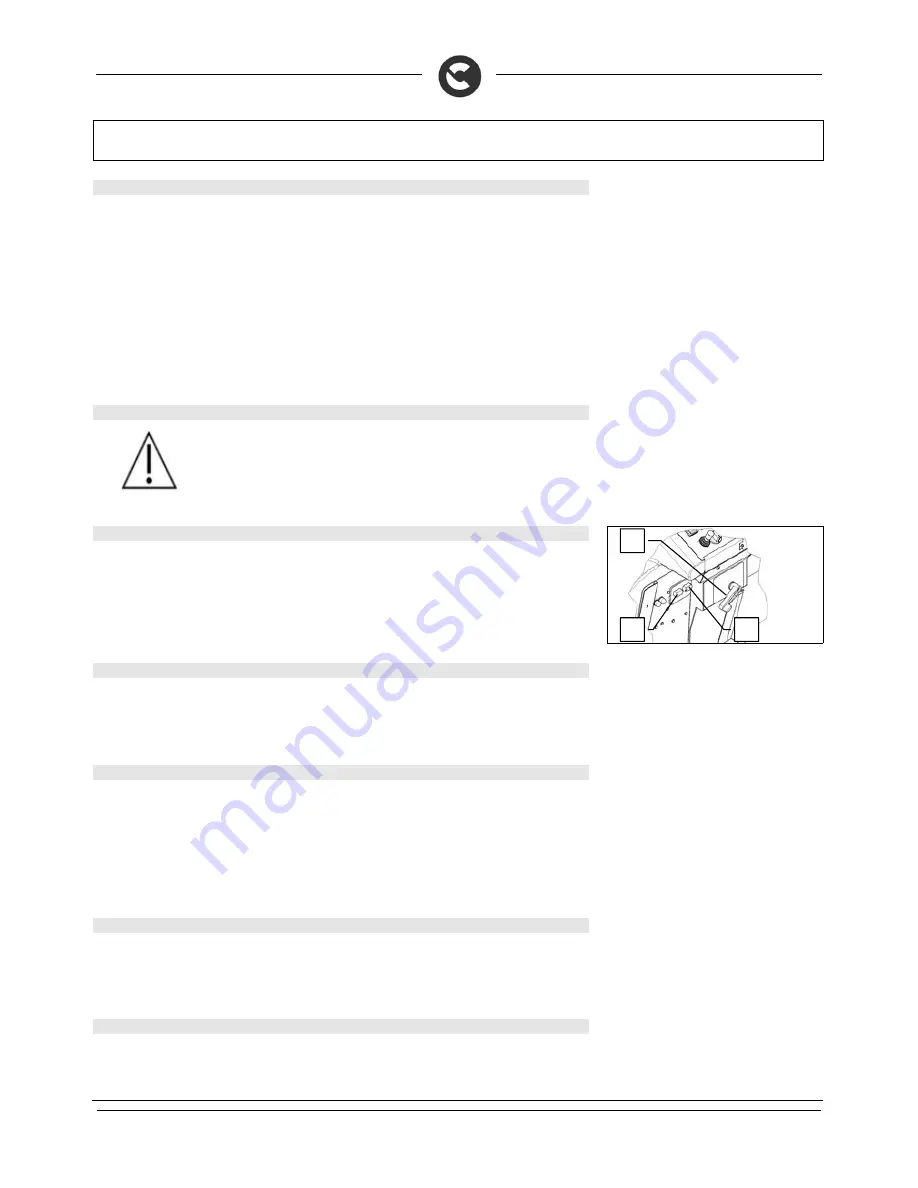

Check that the water/detergent solution release adjustment lever (1) is open

3.

Check that the water/detergent selectors (2-3) are open (for CDS versions only)

4.

Clean the solution filter located at the front of the machine

5.

Make sure the detergent solution distribution tank (on the brush head unit) is not clogged

72.

THE SQUEEGEE DOES NOT DRY PERFECTLY

1.

Check the squeegee is clean

2.

Check the squeegee settings (see “MACHINE PREPARATION”)

3.

Clean the entire vacuum unit (see “WEEKLY MAINTENANCE”)

4.

Replace the rubbers, if worn

73.

THE MACHINE DOES NOT CLEAN WELL

1.

Check the state of wear and tear of the brushes and, if necessary, replace them. The brushes should

be changed when the bristles are about 15mm long. To replace them, see “REPLACING THE

BRUSHES”, or “DISASSEMBLING THE BRUSHES” and “ASSEMBLING THE BRUSHES”. Working

with over-worn brushes may cause damage to the floor

2.

Use a different kind of brush to the one fitted as standard. For cleaning floors where the dirt is

particularly resistant, we recommend the use of special brushes supplied upon request and according

to needs (see “CHOOSING AND USING THE BRUSHES”)

74.

EXCESSIVE FOAM PRODUCTION

Verify that a low foam detergent has been used. If necessary, add a small quantity of anti-foam liquid to the

recovery tank.

Remember that, when the floor is not very dirty, more foam is generated. In this case the detergent solution

should be more diluted.

75.

THE SUCTION MOTOR DOES NOT FUNCTION

1.

Check whether the recovery tank is full and, if necessary, empty it

2.

Check the float switch on the suction cap is working well (see also “CLEANING THE RECOVERY

TANK” under “DAILY MAINTENANCE”)

2

1

3